Over the last two decades, thin films with a cross-web gradient structure have received growing attention as an area of research due to their improvements in performance and material properties. Used as coatings to modify and/or amplify the functionality of a surface/substrate, polymer thin films have a wide number of applications across industries, including microelectronics, semiconductor devices, wireless communications, integrated circuits, and solar cells. To date, patterned thin films have been fabricated using several techniques. However, these techniques are often material dependent and wasteful and are not scalable or highly efficient.

Innovative Manufacturing Technique Enhances Gradient Thin Film Quality and Scalability

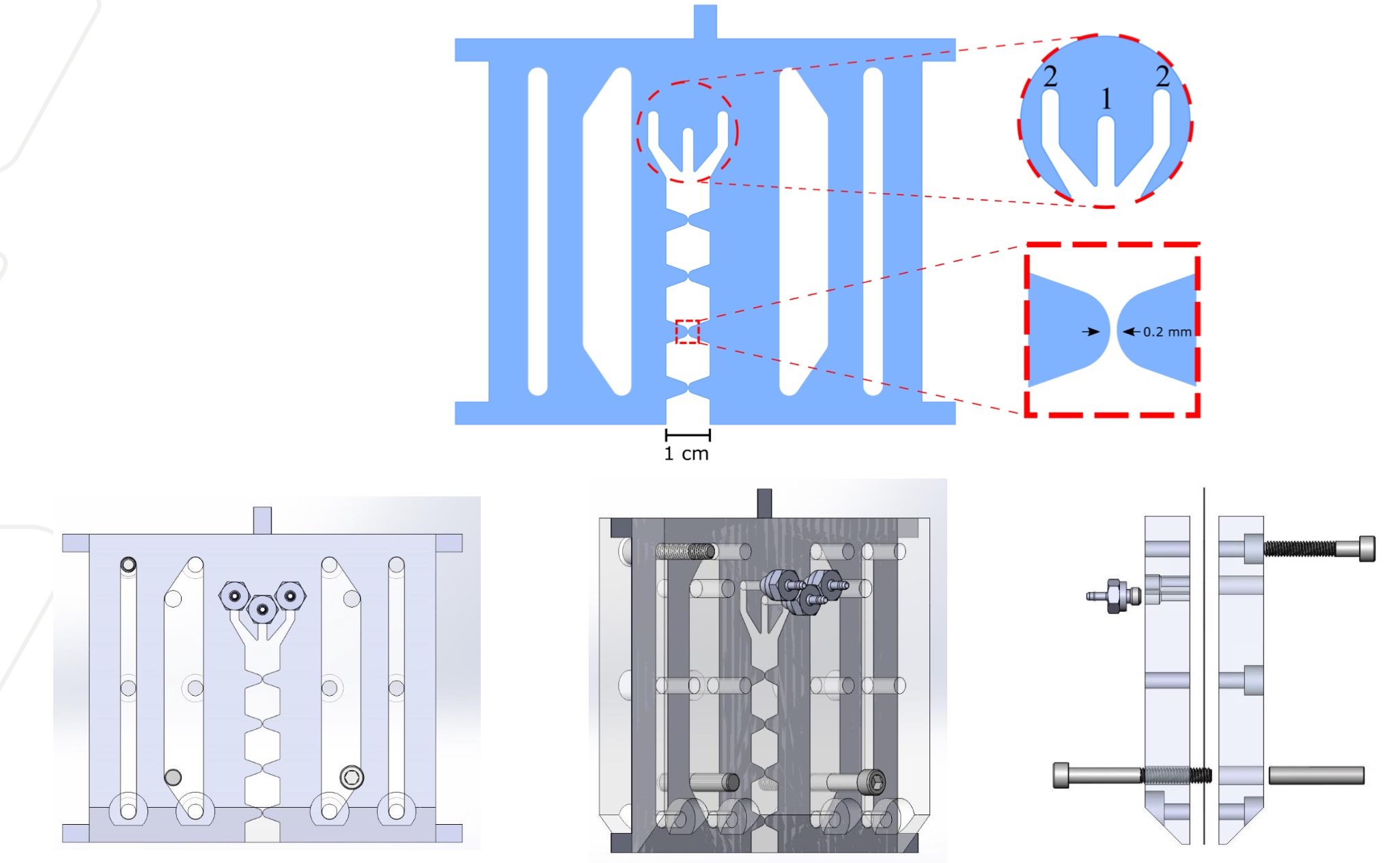

Slot die coating, a well-known scalable manufacturing process, in conjunction with a custom roll-to-roll imaging system allows for the efficient, rapid production of high-quality gradient thin films. Additionally, this innovative manufacturing technique is flexible, as it can use different materials to form the gradient structure. The process works by forcing two fluidic materials into the slot die simultaneously and by manipulating the viscous, diffusion, and inertial forces. The materials intermix with the aim of having a 50% mix along the centerline of any two contiguous stripes. This manufacturing process has been tested (with different coating parameters, substrates, etc.), and the practicality and functionality of the pattern has been demonstrated.

- Scalable production: The combination of slot die coating with a custom roll-to-roll imaging system allows for continuous scalable fabrication at a faster rate than current manufacturing processes.

- High-quality: The manufacturing process provides higher quality patterned thin films than existing manufacturing techniques.

- Flexible: Broad material combinations can be used in the process to form the gradient structure, which is an improvement over existing techniques that are material dependent.

- Cost-effective and green materials: Fluidic materials are selected for the process if they are water-soluble, non-toxic, known for functionality, and cost-effective.

- Proven: The practicality and functionality has been proven through experimentation, suggesting the manufacturing technique has the potential for increased application of patterned thin films across multiple industries.

Graded thin films are used across multiple industries, including:

- Electronics and microelectronics industry use, such as flexible electronics encapsulation, lab-on-a-chip biosensors, thermoplastics scaffolds, and electrically conductive shielding foam

- Energy technologies and environmental systems, including solar cells and heterofibrous scaffolds for lithium-ion batteries

Slot die coating on roll-to-roll process