This device efficiently dissipates large heat fluxes from hot spots produced inside computer chips, photonic and RF devices and other optoelectronics, and miniaturized high density power conversion devices. When placed in contact with a hot spot (a small area that dissipates a large amount of thermal energy), the device enables highly efficient 3D heat spreading and evaporative cooling by way of an extended meniscus created by a “liquid bridge” formed in the confined volume over the hot spot. It also uses capillary forces and enhanced vapor removal brought about by the large pressure differential produced when capillary pressure rises above background vapor pressure in order to enhance the evaporative cooling.

Georgia Tech’s design exploits high cooling capabilities associated with phase-change heat transfer (i.e., liquid to gas) while avoiding problems that arise from surface dry-out and overheating when heat flux exceeds critical levels. A wide range of operating parameters and working fluids—including water and dielectric fluids—can be used to achieve rapid heat dissipation.

- Effective: Dissipates large heat fluxes via 3D heat spreading and evaporative cooling that could approach kW/cm2 and beyond while keeping the surface temperature under 90oC

- Preventive: Mitigates coolant dry-out at the critical heat flux levels that result in a rapid and large temperature rise and thus cause device burn-out

- Efficient: Exploits high cooling capabilities associated with phase-change heat transfer through evaporation

This technology is useful for thermal management in heat-generating structures:

- Microelectronics

- Power generation and conversion devices

- Chemical reactors

- Optoelectronics, photonics, and RF devices

High performance electronic circuits and chips require enhanced cooling via rapid heat dissipation to prevent deleterious effects on performance. This is especially true for computer chips, power conversion, and communication devices. Two-phase heat dissipation systems are generally limited by the danger of the liquid coolant dry-out at critical heat fluxes.

Georgia Tech’s innovation overcomes fundamental limitations of two-phase cooling techniques with a design that promotes efficient thermal management through capillary confinement of the evaporating film and an efficient mechanism for vapor removal.

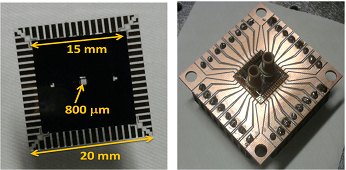

Prototypes of capillary trap and vapor pump thermal management devices