Unwanted bacteria growth can cause the formation of biofilms on medical device surfaces, in city infrastructures like water distribution systems, and on food processing and other industrial equipment. These biofilms can cause problems such as clogging and biocorrosion; serve as reservoirs for pathogens and antibiotic-resistant genes; and cause process failures, material waste, and safety issues.

Antimicrobial surfaces provide safer, more effective bacteria inactivation

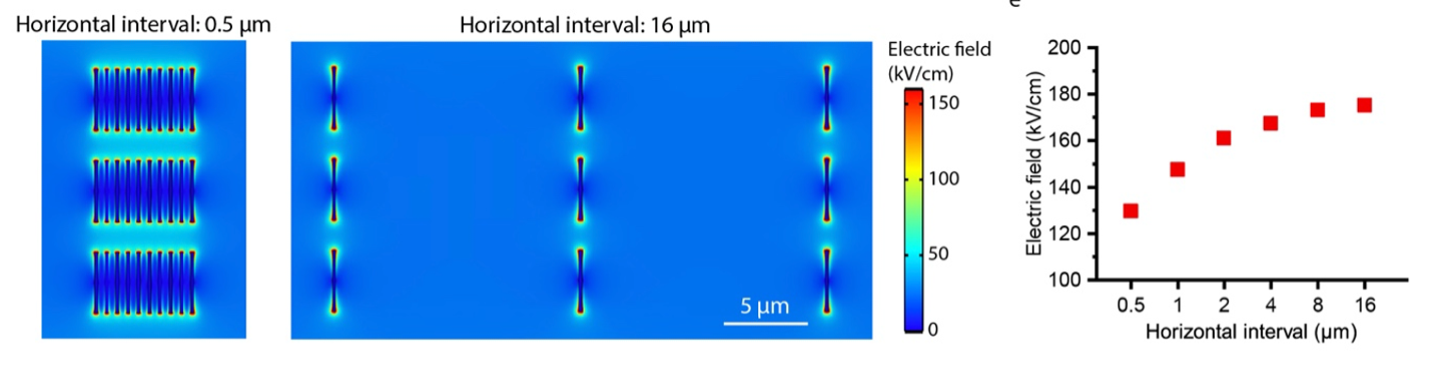

Applying electrode patterns to a surface generates a strong electric field that will inactivate bacteria and inhibit biofilms quickly and efficiently. Differing the patterns by varying the width and spacing between interdigitated electrodes enhances the electric field and its ability to inactivate bacteria. Another design uses floating nanotips with high aspect ratios densely arranged between the positive and negative electrodes. The electric field will be largely enhanced at the ends of the nanotips, leading to bacteria inactivation and biofilm inhibition.

This antimicrobial surface can be applied to flat surfaces, curved surfaces, and soft structures and has many potential applications.

- Effective: Studies have demonstrated that both Gram-positive and Gram-negative bacteria, including antibiotic-resistant bacteria, are inactivated by electric field treatment on the antimicrobial surface.

- Safe: Because it uses a physical process targeting cell membranes or capsid, electric field treatment is chemical-free and less likely to induce antimicrobial resistance.

- Increased efficiency: Requires very short electrical pulses to achieve effective bacteria inactivation, potentially leading to higher antimicrobial efficiency.

- Versatile: Has many potential applications and can be applied to flat surfaces, curved surfaces (such as a pipeline), and soft structures.

- Drinking water distribution systems

- Industrial equipment (e.g., for food or drink processing)

- Cooling systems

- Medical or surgical devices

- Home appliances

- Soft materials (e.g., used for wound healing)

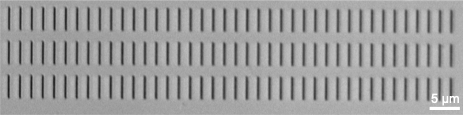

An electrode pattern with high aspect ratio nanotips distributed between the two electrodes.

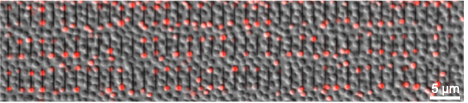

Bacteria inactivated (in red) by the floating nanotips.

(left and center) Simulation images of the nanotip structures with different horizontal intervals. (right) The nano-enhanced electric field over the horizontal interval between nanotip structures.