Monitoring of cell culture bioreactors is critical to process control and optimization for multiple applications, including production of monoclonal antibodies, vaccines, recombinant proteins, stem cells, and gene therapy. Because current automated bioreactor sampling systems primarily use lines of tubing to transfer samples to storage locations, they frequently have issues with cross-contamination and loss of media within the tubing lines. Controlling contamination with these systems requires skilled staff trained in thorough cleaning and maintenance of equipment and an effective preventative maintenance program.

New automated sampling system maintains integrity of collected samples

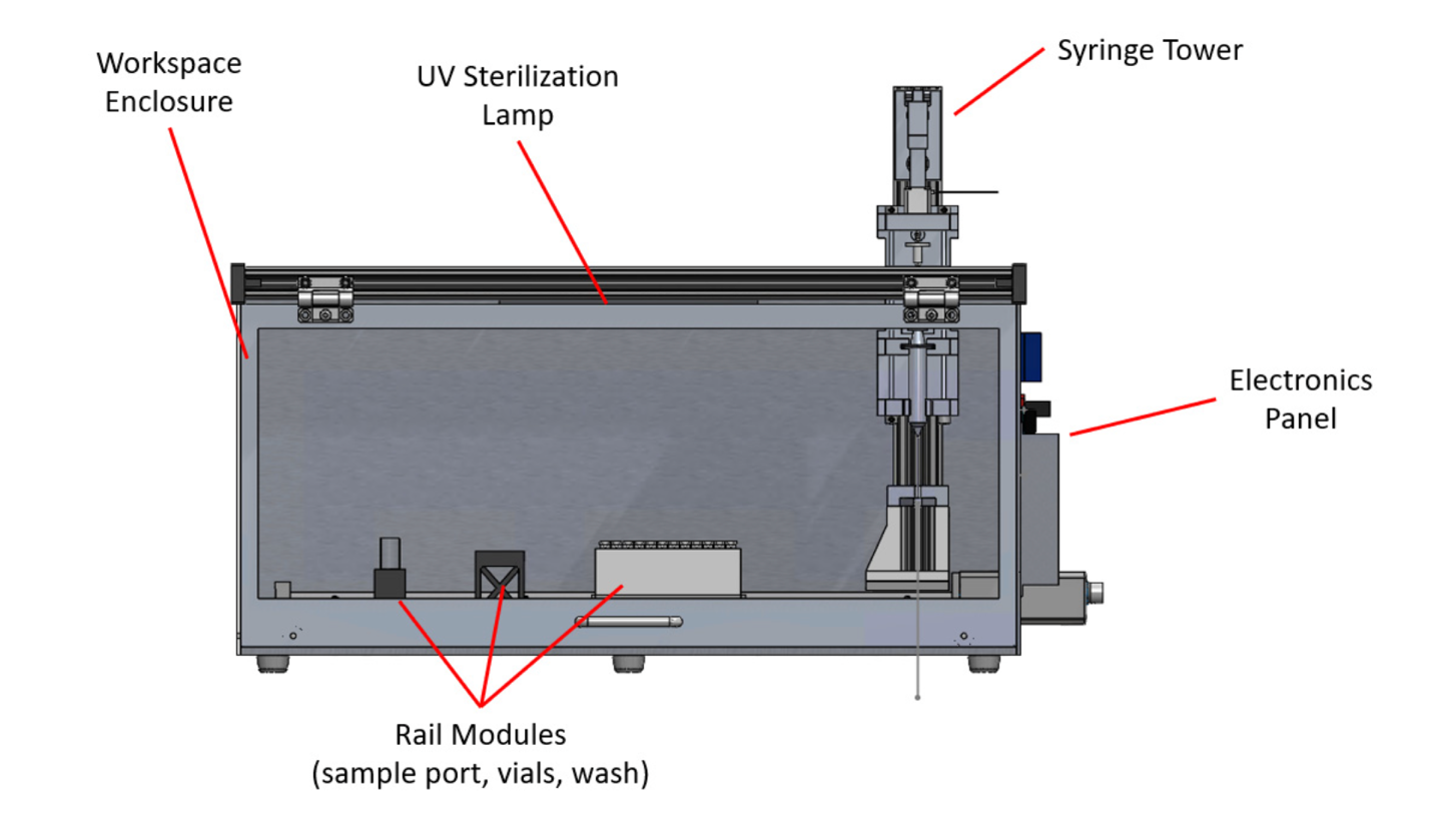

This gantry-style multi-axis actuator uses a syringe pump end effector to extract samples from an in-line rubber septum that is within a tubing-based system, depositing the extracted samples into sealed cryovials for storage. The disposable syringe can be replaced after each sample to eliminate nearly all possibility of cross-contamination and maintain sample integrity.

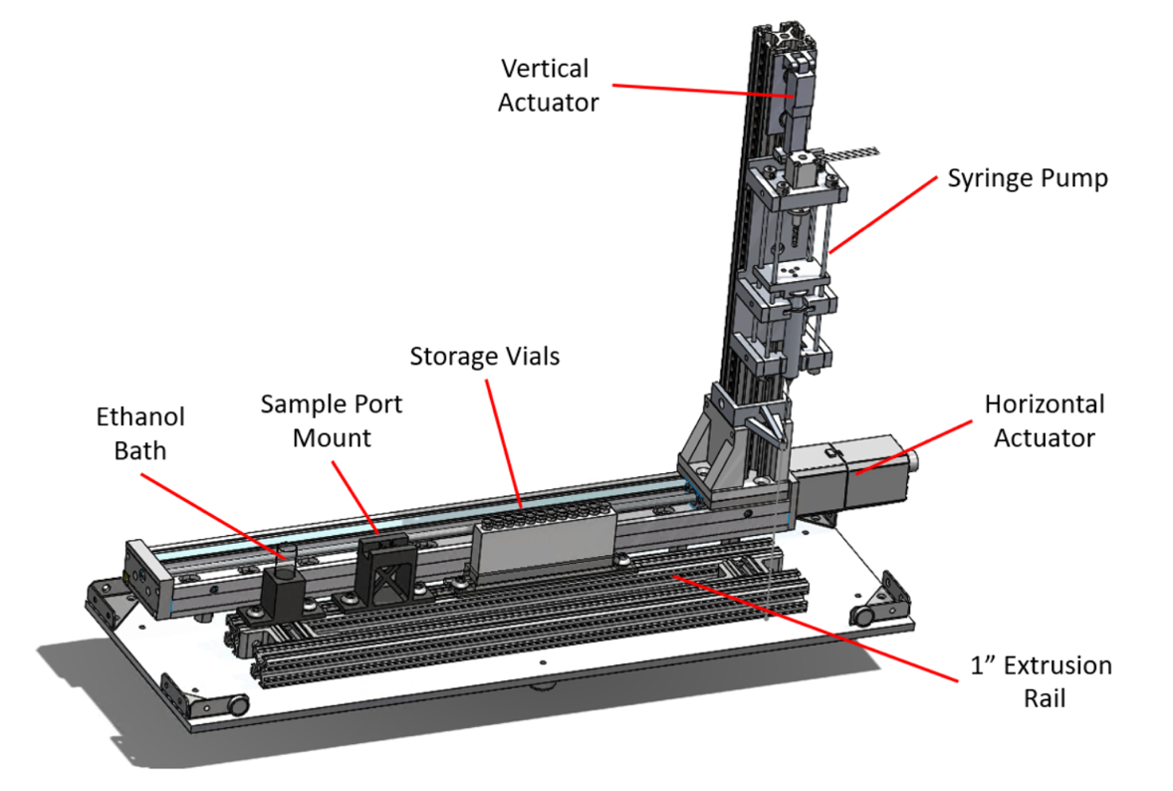

The system comprises a microcontroller and corresponding electronics that control the horizontal actuator, syringe pump, and a vertical actuator. The vertical actuator moves the syringe pump assembly to retrieve a disposable syringe stored in the storage vial. The samples can then be transferred between, for example, a bioreactor recirculation line and sample cryovial. After the transfer, the disposable syringe can be detached from the syringe pump assembly and the process repeated for the next sample. The automated sampling platform can be used with any type of samples and collection.

- Maintains sample integrity: Automatically changing the syringe between samples will eliminate nearly all possibility of cross-contamination between samples.

- Simplifies sampling: The automated design includes a processor programmed to execute control of the actuator for sampling at specified times and can be integrated with sensors to trigger samples based on specific sensor readings.

- Reduces costs: In addition to savings related to reduced cross-contamination, automated sampling can further lower costs by reducing hands-on time and speeding sampling.

- Offers flexibility: The platform can be used with any type of collected sample and can be used with a wide range of bioreactors.

Designed for use in cell culture bioreactors with tubing access for a wide range of applications including production of monoclonal antibodies, vaccines, recombinant proteins, stem cells, and gene therapy.

The automated sampling platform

The syringe tower includes a vertical actuator and a syringe pump. In this example, the tower is coupled to a horizontal actuator that is configured to move a storage vial, a sample port mount, and an ethanol bath along an extrusion rail.