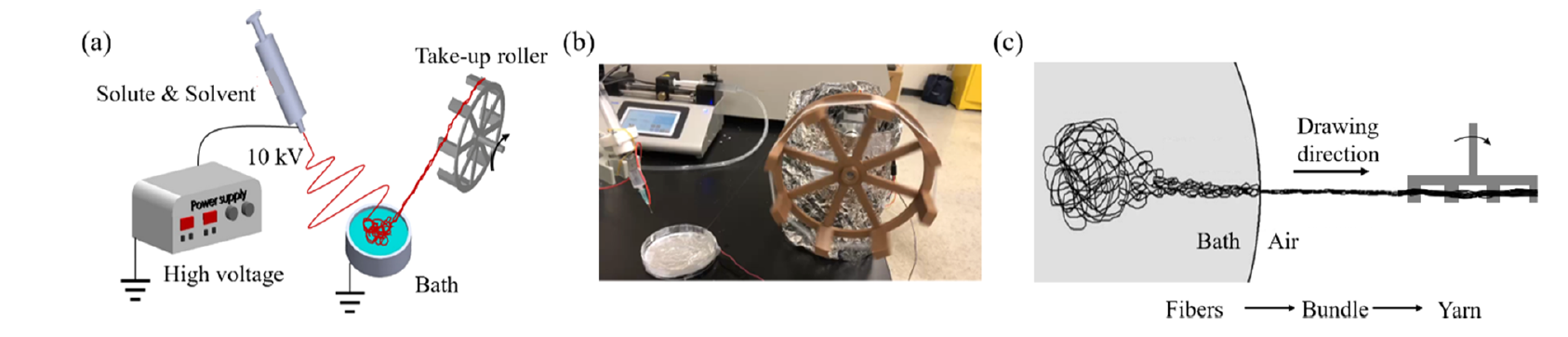

These new methods for tissue engineering address the challenges of building scaffolds that exhibit the properties of real human tissue. Georgia Tech’s innovations leverage a method using fabricated polycaprolactone (PCL) yarns by wet electrospinning. The PCL yarns can be used for constructing a textile-based sandwich scaffold that—unlike existing scaffold fabrication methods—mimics the strain-stiffening behavior observed in human tissues. Additionally, carbon nanotubes (CNT) can be incorporated into the yarns, providing conductive properties to the polymer composite.

To construct the textile-based sandwich scaffold, endothelial cells are seeded on the PCL yarns and can align and elongate along the yarn direction. Then, the yarns are crocheted into a textile fabric, which becomes the middle layer between two electrospun mats. Cells are also seeded on the outer layers, which proliferate and penetrate the scaffold. The textile-based sandwich scaffold notably exhibits the potential to mimic the mechanical, physical, and biological properties of human skin and other tissues.

Using a modified process, a CNT-based polymer composite can be generated by wet electrospinning PCL yarns into a bath containing CNT. The process eliminates the modifications previously needed to incorporate conductive CNTs into polymers—more readily leveraging their advantages in regulating electroactive cells for tissue engineering applications. The resulting composite yarns exhibit good biocompatibility and may be used in a range of construction techniques for vascular scaffolds. Georgia Tech’s advances provide a novel method for applying polymers, CNTs, and other functional materials into tissue engineering applications.

- Biocompatible: Exhibits good biocompatibility of the yarns fabricated using a wet electrospinning technique (results shown within a limited range of CNT concentration in the bath)

- Purposeful: Mimics the strain-stiffening behavior of human tissue, unlike other scaffolds that exhibit strain-softening of their synthetic materials

- Demonstrated: Exhibits the ability to guide cell anisotropic arrangement as well as support cell proliferation and infiltration in in vitro biological tests

- Robust: Enables adjustment of process parameters during the yarn fabrication and textile construction process, allowing adjustment of the maximum stress of the scaffold from 3.74 to 11.82 MPa, the maximum strain from 0.16 to 2.37, and the elastic modulus from 2.10 to 18.05 MPa – all within the ranges of that of human skin

- Enabling: Eliminates requirements for miscible solvents or CNT surface modifications, realizing the advantages of CNTs to help regulate adhesion, mitigation, and proliferation of electroactive cells for tissue engineering applications

- Bioengineering

- Tissue engineering, including vascular and skin

- Regenerative medicine

- Wound repair and regeneration

- Drug testing

- Disease modeling

- Fabrication of polymer/CNT composite yarns for use in:

- Sensors and electronics

- Aerospace

- Sporting goods

The demand for organ repair and transplantation, and a shortage of available donors, necessitate the clinical need to develop innovative strategies for repair and regeneration of injured or diseased tissues and organs. Tissue engineering, which aims to create living biological substitutes, offers promising avenues to address the organ shortage. Yet designing and fabricating scaffolds with tissue-like properties is a key challenge. Failure to mimic properties of human tissues can have negative results in tissue integration and regeneration. A formidable hurdle is mimicking the mechanical properties of human tissues. This is because they have strain-stiffening properties, while most synthetic biopolymers have strain-softening properties.

Georgia Tech’s new methods for tissue engineering directly address these challenges, enabling a scaffold that takes advantage of conductive CNT/polymer yarns. These promising advances exhibit robust strain-stiffening properties, along with biocompatibility and a supportive environment for human cell proliferation.

(A) Schematic of wet electrospinning; (B) Experimental setup of wet electrospinning; (C) Schematic of fabricating fibers, bundles, and yarns