Industrial textile manufacturing currently requires extensive chemical waste for the dyeing of synthetic fabrics like polyester. The wastewater from these processes requires extensive treatment to remove the synthetic chemicals before becoming acceptable for release. Textile manufacturers are seeking new methods to provide optimal color with less environmental impact.

Reducing water and energy waste without losing coloring capacity

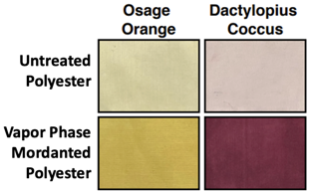

Vapor Phase Infiltration (VPI) infuses polymers, including fabric fibers, with small amounts of inorganic materials. These infused inorganic species can act as mordants for more effectively binding dyes, including naturally produced dyes that are fully water soluble and benign to the environment. Resultant fabrics have similar handleability but can be vibrantly dyed, which in initial evaluations is not overly susceptible to loss upon washing. Furthermore, VPI does not depend on the same extreme energy demands to produce high heat settings or wastewater management as the existing industry standards require.

- Eco-friendly: Removing the need for water-polluting chemical carriers that existing polyester dyeing methods require decreases the risk of synthetic pollutants in waterways.

- Energy and cost saving: VPI does not require the excessive heat production as current dyeing processes, thus manufacturing energy costs are reduced.

- Stronger dye adhesion: Infusing polyester material with inorganics provides a strong base for dye adhesion that can be increased by controlling VPI process parameters.

- Improved quality: Utilizing the VPI method can strengthen the dyability of polyester without losing the fabric’s flexibility and wash-fastness.

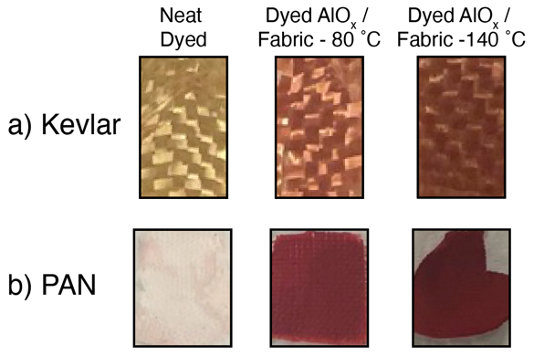

- Wide applicability: Increased dye adhesion because of VPI has been observed in materials beyond polyester, including Kevlar and polyacrylonitrile (PAN).

- Textile dyeing and finishing

- Commercial textile manufacturing

- Medical textiles

- Additional applications due to improved molecular adhesion include medical devices and others

Figure 1. Untreated (top) and vapor phase infused (bottom) polyester fabrics undergoing a similar dying process with the natural dyes osage orange (left) and dactylopius coccus (right). Fabrics after vapor phase mordanting (bottom) are clearly more receptive and vibrantly dyed.

Figure 2. Kevlar and PAN, controlled and VPI-altered samples with alizarin dye