Poor fit of current filtering facepiece respirators (FFR) results in lack of protection and pressure injuries

Protection of health care workers is a national imperative, and personal protective equipment (PPE) is the first line of defense. The COVID-19 pandemic has reinforced the importance of PPE, especially FFRs (e.g., N95), for health care workers on the front lines.

Typical FFRs come in limited sizes that don’t accommodate variations in size, gender, and ethnic diversity within the user population. The respirators exert pressure on the face that affects both the comfort of the wearer and leakage at the faceseal. When worn for long durations or excessively tightly to prevent leakages, such as in a healthcare setting, the pressure exerted on the face can lead to pressure injuries.

Additionally, there is no quantitative metric or indicator to inform users that the respirator has been donned correctly for adequate protection while also being comfortable. Changes in facial expressions along with repeated removal and adjustments of the respirator can decrease effectiveness and protection. Having a sense of security for health care professionals is a critical factor in enabling them to perform at their best under trying circumstances without compromising their personal safety.

Likewise, the poor air quality caused by wildfires and pollution as well as infectious disease outbreaks such as COVID-19 have highlighted the importance of respiratory protection for the public, especially children for whom no respirators are currently available in the market.

New RPD design improves comfort and protection, while bringing peace of mind for wearers

Respirator comfort, protection, and safety are vastly improved with this custom-fit design that incorporates a reusable frame, sensors that continuously monitor fit, the ability to use multiple disposable filters with varying degrees of filtration, and analytics to prevent pressure injuries and inform future design improvements. Using an embedded fabric-based sensor network as part of a real-time fit monitoring system, this RPD can maintain protection throughout the wearer’s movements such as talking, smiling, and yawning. Its flexible design moves with facial profile changes, while the sensors detect and alert the wearer to any leaks. It also prompts the wearer to make adjustments to prevent pressure injuries when wearing the RPD for extended periods of time.

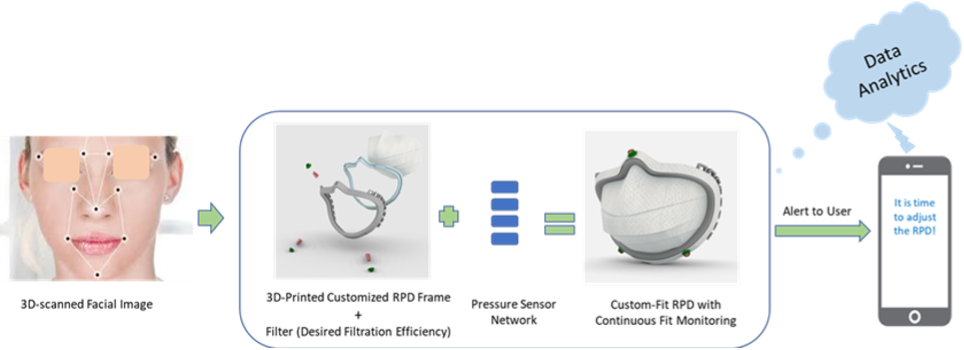

The process begins with digital scanning of the individual’s face and creation of the 3D-printed custom-fit RPD frame. Advanced algorithms inform precise sensor positioning based on analysis of the wearer’s facial profile to ensure continuous monitoring of the fit. The sensors are close to the wearer’s face to capture the changes in pressure at the faceseal when facial expressions change; however, they do not contact the skin to avoid contamination. The sensors are embedded in a flexible base frame with a matching interlocking cover with specially designed screw sets that hold them securely in place. This interlocking mechanism prevents separation during use, secures the filter, and houses a data bus conduit connecting the sensors.

Data from each sensor travels to a printed circuit board outside of the frame, which transmits data to a cloud-based server and to an app accessible on a smartphone or tablet. The system analyzes data and displays a “heat map” of the pressure distribution on the face seal on the mobile device and on a web portal. When the baseline pressure profile changes during use, the system issues an alert through the app to the wearer to adjust the RPD. Upon adjustment that ensures a secure faceseal, the alert is dismissed and the monitoring cycle continues.

Advanced algorithms are used to customize a “fastening hub” for optimum placement of straps and fastening hooks. This ensures the RPD can be donned quickly, easily, and repeatedly, while maintaining secure fit and protection. The RPD is reusable, with the filter discarded after use and the frame decontaminated for the next use.

- Minimizes exposures: Leakage during use is immediately detected and the user alerted to adjust the RPD, minimizing exposures to inhalation hazards.

- Minimizes pressure injuries: Pressure injuries caused by extended respirator use or excessive pressure at the faceseal are minimized through both the customized fit and the alerts when the wearer should remove the RPD or make an adjustment.

- Improves comfort: Customized to fit the wearer’s facial features and incorporating textile-based components, this comfortable RPD flexes and shifts with facial movements.

- Provides peace of mind: This RPD enhances the wearer’s sense of security when working in high-risk environments that may compromise their personal safety, enabling them to concentrate on their jobs more effectively.

- Lowers cost: Reusable components and reduced pressure injuries decrease the total cost of respiratory protection in the workplace.

- Reduces waste: Reuse significantly reduces the quantity of disposable (and not easily biodegradable) N95 respirators discarded in landfills.

- Variable filtration: It provides a customizable degree of filtration by changing the disposable filter to accommodate various environmental or respiratory health conditions, including balancing comfort and degree of protection for individuals with special health conditions (e.g., asthma).

- Saves time: This technology potentially eliminates the need for routine fit testing, subject to regulatory changes, since the RPD fit is monitored continuously.

- Improves future RPD design: Collected data can provide insights to inform RPD designers, occupational medicine physicians, employees, and employers in better understanding the role and importance of respiratory protection in workplace settings.

Respiratory protection for:

- Health care workers

- Any occupation requiring respiratory protection (e.g., first responders, factory workers)

- Individuals – from infants to senior citizens

Concept of custom-fit reusable respiratory protective device with continuous fit monitoring. The user’s face is digitally scanned. The RPD frame is 3D printed from the scan. The filter with the desired filtration efficiency (e.g., N95) is added. A fabric-based sensor network is integrated into the RPD frame to continuously monitor the pressure. (The number and location of sensors can be tailored to suit the facial profile.) The pressure data are transmitted to the cloud and to an app on the smartphone or tablet.