Lack of available organs and tissues to treat disease is a major problem

Organ failure and tissue defects affect millions worldwide, resulting in significant healthcare-related expenses. The lack of available organs and tissues to treat liver disease, renal failure, tissue grafts, and burns is a major problem. While tissue engineering is a potential solution with expanding promise, there is much development needed to make it a viable solution. Cells, biological, or synthetic scaffolds are implanted into the patient to replace or regenerate cells, tissues, or organs to restore normal function. Architected auxetics are specific networked structures designed to exhibit a negative Poisson’s ratio (NPR) in which the material can expand transversally when axially strained under tensional force. They also exhibit a high flexibility with elastic resilience due to their deformation mechanism by the relation rotation of the intersecting joints in the structure. Because of their unique behavior, these biomaterials have potentially broad applications – particularly in soft, compliant tissues like muscles, ligaments, vascular tissues, skin, and fat.

Bioabsorbable 3D auxetic implants provide enhanced flexibility, permeability, and nonlinear behavior

Researchers have developed a new process for generating resorbable auxetic materials for biomedical applications. Novel 3D auxetic frameworks were created by selective laser sintering (SLS)–based 3D printing of Poly-ε-caprolactone (PCL) to serve as a substrate for reconstructing large-volume soft tissue defects. With enhanced compressive flexibility, permeability, and nonlinear mechanical behavior, the technology has the potential to enable generation of implants for improved large-volumetric soft tissue reconstruction by mimicking soft-tissue compliance, while providing increased mass transport capability.

- Superior flexibility: Auxetic implants display high flexibility and nonlinear behavior.

- Multidirectional load bearing: Cubic symmetry provides consistent load bearing in multiple directions.

- Superior permeability: Bimodal, two-scale porosity of large pores between the struts and small pores within the strut offers increased permeability.

- Flexible fabrication method: 3D auxetic implant can be fabricated with customizable mechanical and permeable properties based on target tissue.

- Specialized per patient: Implants can be personalized by fitting the complex anatomic geometry of the defect from patient medical data.

- Rapid mass manufacturing: Compared to other 3D printing modalities, SLS has high design flexibility that allows intricate geometries and rapid mass manufacturing, making SLS the preferred method for creating auxetic architectures.

- As a scaffold for tissue or organ implants (e.g., for breast or facial reconstruction, or for calcaneal fat pad implants) relevant to disease indications that require tissue or organ replacement or repair.

- Other biomedical applications, including wearable medical devices for treatment.

- In vitro 3D soft tissue models (including cardiac and cancer tissue models) for biological assessment, detecting/modeling of disease/disorder, and drug discovery/screening.

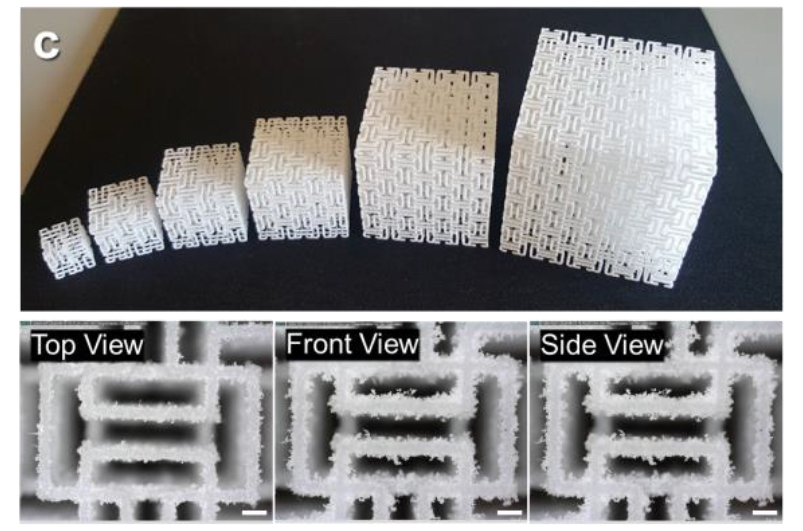

Auxetic cubes created by SLS-based 3D printing of PCL. White scale bars, 1 mm.

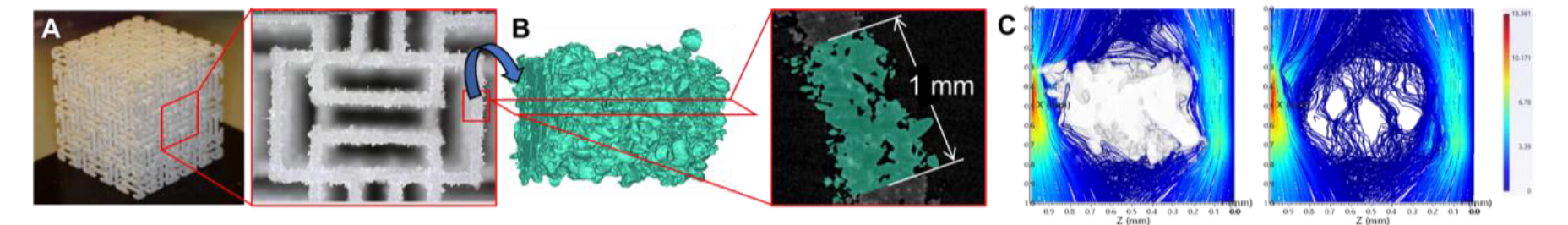

Printing results of auxetic cube. (A) auxetic cube of 26 × 26 × 26 mm (0.5 mm of strut width and 1.2 mm of interval between the parallel struts). (B) Segmented μ-CT scan results of the single strut of the auxetic cube. (C) Flow infiltration through the single strut of an auxetic cube.

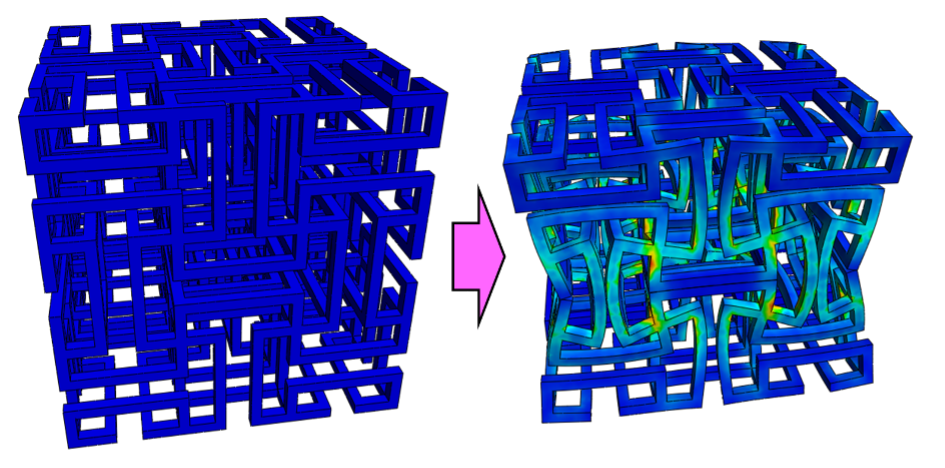

Simulation result of the auxetic cube that shows the negative Poisson’s ratio deformation behavior under compression.