Researchers at Georgia Tech have developed a novel system of pristine bismaleimide (BMI) through a unique high-speed shear mix (HSSM) processing method. This method produces material with an impact strength three to four times greater than the typical BMI. While carbon fiber reinforced BMI composites have long been known for their high-strength and heat-resistant qualities, the brittleness of the material makes it vulnerable to impact-induced damage. This centrifuge-based HSSM method, however, rearranges the molecular geometry of the material in order to increase its toughness and significantly reduce its brittle qualities. The resulting BMI plastic overcomes the limitations of conventional BMI and can be reproduced for large-scale utilization in a variety of industries requiring high-performance materials.

This technology also does not require the addition of chemical additives, as is typical in current models for BMI development. Without the need for extensive chemical processes, BMI’s potential for industry use increases. This Georgia Tech method allows BMI to retain its balanced performance qualities in high-impact and high-temperature scenarios while reducing its risk of damage.

- Highly durable: Demonstrates an impact strength of up to 69 kilo joules per square meter—a 392% increase over BMI that did not undergo HSSM processing

- High-fidelity: Overcomes the typical limitations of BMI without the use of chemical additives

- Straightforward: Requires only simple, conventional equipment for development

- Aerospace and defense industry

- Automotive industry

- Rubber materials

- Electronic components

The development of new polymeric systems has been driven by high-tech industry demands for materials that are not only temperature resistant but also lightweight and highly durable. Inspired by natural observations of fracture energy dissipation like in the structural hierarchies of bone and spider fibroin composition, the Georgia Tech research team explored the impact of molecular rearrangement on the overall toughness of BMI. This rearrangement produced a BMI system that retains its strength and heat-resistant qualities but has reduced brittleness. Thanks to its varied and heterogenous molecular nature, BMI makes the ideal candidate for experimentation of this kind.

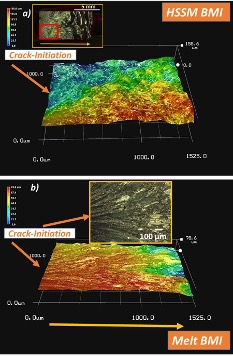

These images compare roughness qualities in both an HSSM BMI and a simple melt BMI at a crack initiation zone.