Current membrane-based filtration techniques exhibit poor solute selectivity

Addressing the global water shortage has led to the development of membrane-based water purification techniques for unconventional water resources, such as wastewater, brackish water, and seawater. Many membranes use nanofiltration (NF) to produce safe and clean water. While thin-film composite (TFC) NF offers superior energy efficiency and better water quality compared to conventional water treatment processes, it lacks the control needed for both permeability and selectivity. For example, the mineral phosphorous is rapidly being depleted in nature, but existing filtration processes have high retention of phosphorous, which limits the recovery of the mineral from wastewater. Most current filtration technologies are designed to reject solutes based on size, which gives the membranes a tight structure with poor solute-solute selectivity.

There is great need for a selective NF membrane that can achieve a high recovery ratio of essential nutrients/fertilizers that are free of contaminants of emerging concerns (CEC).

Tailored membrane overcomes the permeability-selectivity trade-off

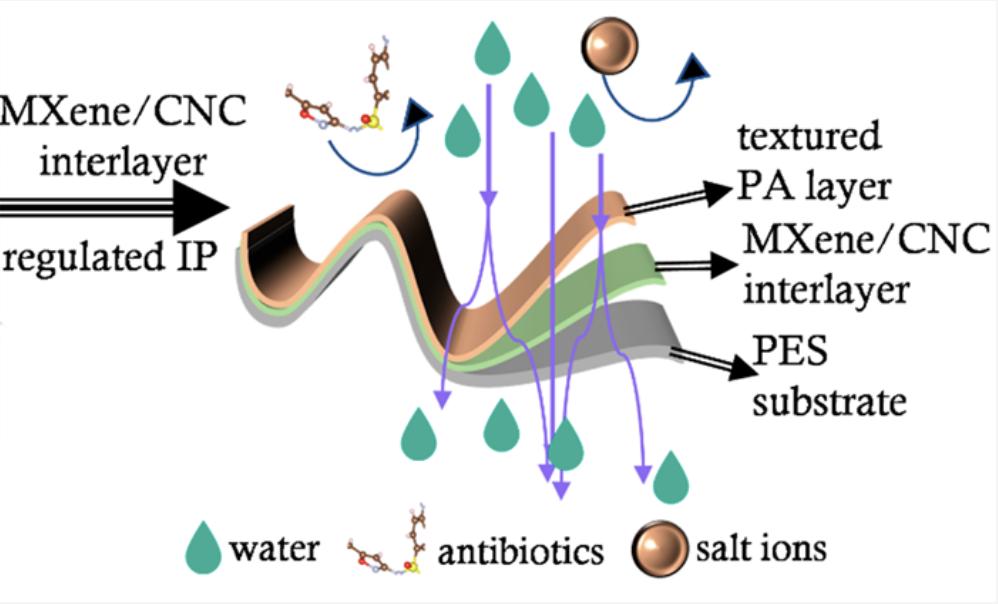

This innovative nanofiltration membrane can remove CECs—including pharmaceuticals, personal care products, per- and polyfluoroalkyl substances (PFAS), and heavy metals—while simultaneously recovering nutrients, such as nitrogen and potassium, which is not possible with current technologies. A new fabrication method introduces a nanomaterials-based interlayer that is deposited on a porous support membrane followed by an interfacial polymerization (IP) process at the interlayer surface. The interlayer is a hybrid two-dimensional (2D) titanium carbide (MXene) and biodegradable cellulose nanocrystal (CNC) framework that is regulated by the IP process. The resulting sandwich-like TFC NF membrane comprises a microporous support, a nanomaterials-based interlayer, and a top thin selective layer. It has a textured surface structure with a large surface area and a highly cross-linked polyamide (PA) network.

This 2D, materials-based hybrid framework can be used to design custom high-performance separation membranes with broad applications in water purification, water reuse, and resource recovery.

- Customizable: This technology adjusts the weight ratios of Mxene to CNC and the interlayer thickness, thereby tuning the membrane structure and surface properties (e.g., membrane pore size, membrane hydrophilicity, surface charge density, etc.) for selective removal of CECs and recovery of valuable components.

- Increased permeability: The enlarged membrane surface area, combined with the gutter effect of the highly permeable interlayer, contributes to substantially enhanced water permeability (nearly doubled) without compromising the rejection of various salts and emerging contaminants.

- Enhanced nutrient recovery: Achieves high-performance recovery of essential nutrients/fertilizers that are free of CECs.

- Safer: This new type of nanofiltration membrane can remove CECs, which may have an ecological and human health impact.

Membrane-based filtration for:

- Wastewater treatment

- Water purification and reuse

- Resources recovery, particularly the essential nutrients nitrogen and phosphorous

Diagram showing membrane layers and filtered water passing through while salt ions and antibiotics are retained.