GT innovators have developed an optical projection technique that improves printing quality for a novel additive manufacturing strategy, enabling cost-effective, large-scale 3D nanoprinting.

Femtosecond projection two-photon lithography (FP-TPL) is a nanoscale 3D printing technique that fabricates tiny structures a thousand times faster than conventional TPL techniques, without sacrificing resolution.

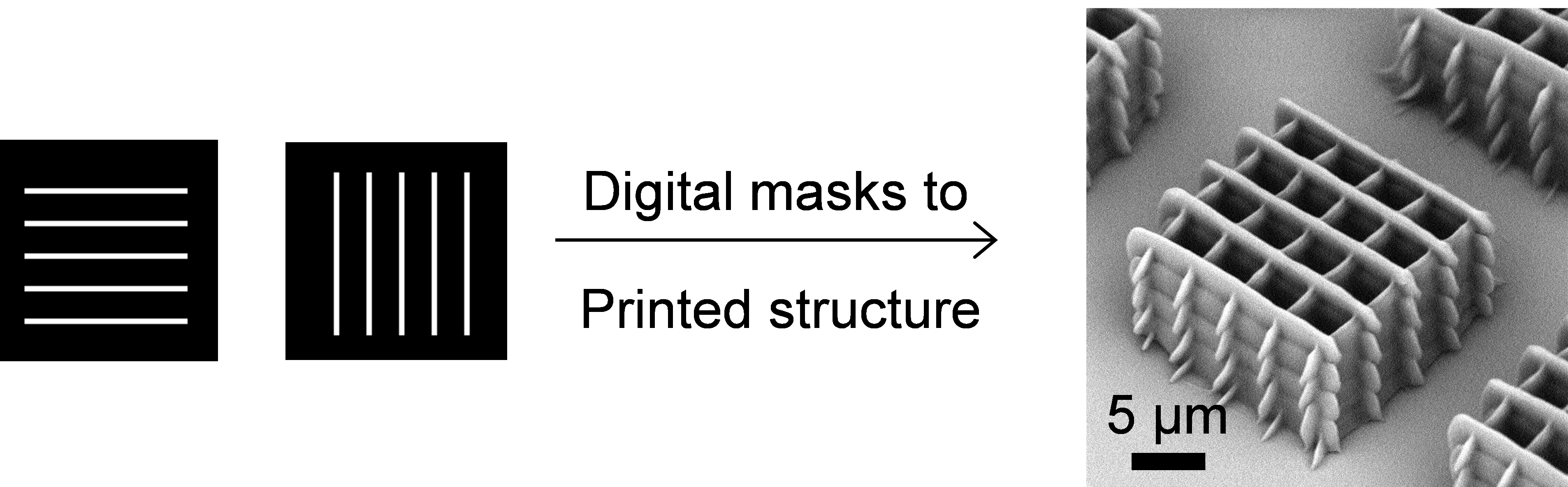

However, the technique requires tuning process parameters—including photopolymer material properties—to minimize defects due to over-polymerization. Georgia Tech researchers have altered the optical projection technique to control over-polymerization defects without the need to tune the photopolymer composition. This modification further reduces the aspect ratio of the submicron features from more than 2 to 1.2, resulting in well-defined structures and transforming FP-TPL into a more robust process suitable for high-throughput, high-quality 3D printing of micro- and nanoscale structures.

- High-performance: Enables a powerful process for high-throughput 3D printing of micro- and nanoscale structures

- Efficient: Reduces defects during printing to improve yield and decrease excess printing commonly observed with FP-TPL

- Improved: Broadens the applicability of FP-TPL to printing of functional micro- and nanoscale structures

- Photonic crystals

- Mechanical metamaterials

- Micromachines

- Miniaturized optics

- Flexible electronics

- Bio-scaffolds

Current technologies for fabricating complex 3D micro- and nanoscale structures are limited to point-by-point writing techniques that are very slow. For example, printing a millimeter cube of material can take up to 100 hours. Therefore, many promising devices that use these structures cannot be printed at the high throughputs required to scale them up for industrial use. The FP-TPL printing technique improves upon previous technologies by increasing the rate by a thousand times without comprising the sub-micrometer feature size resolution. This Georgia Tech innovation further improves upon the FP-TPL printing process by reducing defects during printing, which will improve yields and reduce time and costs associated with wastage.

3D printing with submicrometer features through projection of arbitrarily patterned temporally focused femtosecond light sheets. Printing errors can be minimized by appropriately structuring the digital masks and controlling the projection sequence.