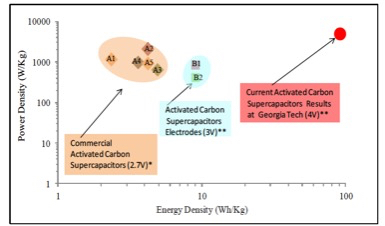

This technology is a nanostructured carbon with high surface area and high energy density designed for energy storage in supercapacitors and hybrid batteries as well as capacitive water desalination. It is synthesized via a low-cost, scalable process of creating atomic layer thick carbonaceous fragments that increase the surface area of polyacrylonitrile (PAN) materials. Specifically, the Georgia Tech research team has developed PAN films, PAN powder, and PAN-CNT (carbon nanotube) composites with an activated carbon surface area up to 3,600 m2/g—substantially more than the 2,630 m2/g achievable in a single graphene layer. This carbon can be fabricated into supercapacitor electrodes that provide as high as 200 F/g capacitance and 50–90 Wh/Kg energy density, significantly more than the current state of the art.

Testing has shown that a supercapacitor fabricated with this PAN carbon maintains capacitance after 40,000 charge/discharge cycles, and a lithium-ion battery maintains capacity even after 30,000 charge/discharge cycles. Researchers have also demonstrated significant improvements in capacitive water desalination as compared to commercial activated carbon.

- High performance: Achieves average energy densities as high as 90 Wh/Kg

- Scalable: Leverages a low-cost PAN fabrication process that dramatically increases surface area

- Widely applicable: Demonstrates potential for advances in a variety of energy storage and capacitive water desalination applications

- Supercapacitors and ultracapacitors

- Hybrid batteries

- Electric vehicles

- Backup energy for low-power equipment

- Voltage stabilizing and energy harvesting/recovery

- Water desalination

- Methane and hydrogen storage

The applications of current commercially available activated carbon are limited because of its relatively low surface area, pore volume, and electrical conductivity. The supercapacitors and batteries made from this commercial activated carbon have relatively low energy storage capacity. This Georgia Tech nanostructured carbon has a narrow pore size distribution and allows for a high atomic weight percentage of carbon in the supercapacitor electrode. It is also designed to fabricate electrodes with high in-plane electrical conductivity. These characteristics improve the technology’s long-term performance and dimensional stability.

A comparison of commercial and experimental activated carbon-based supercapacitors.