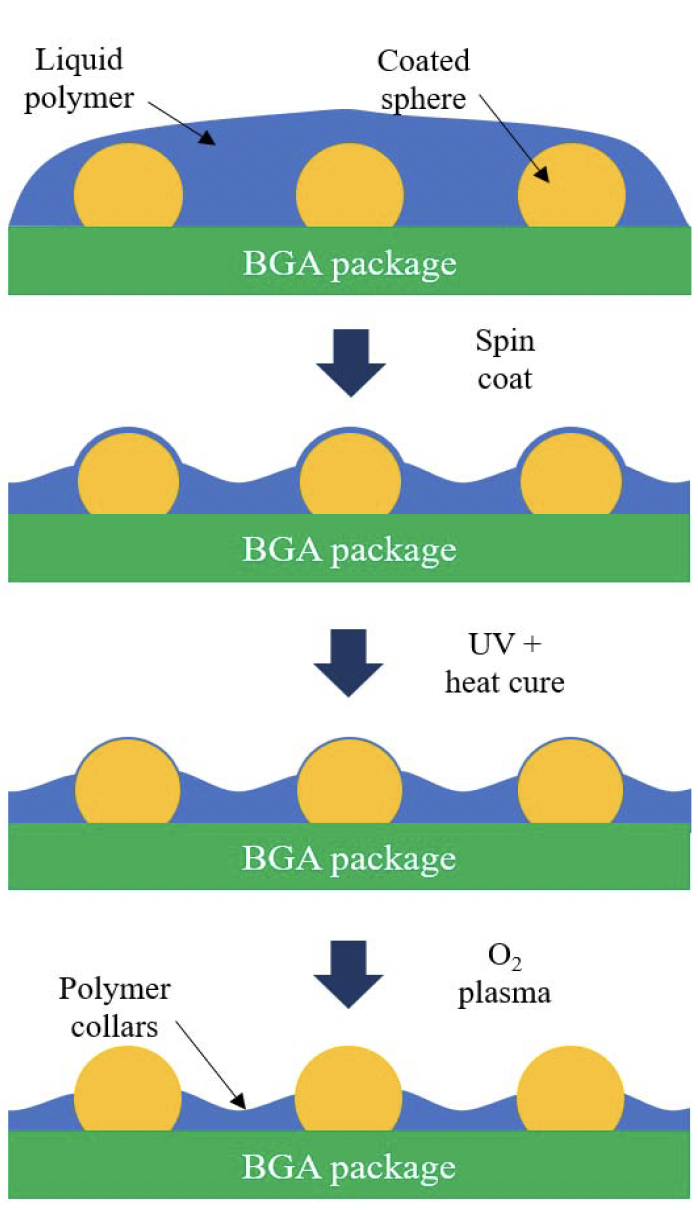

This technology applies spin-coated polymer collars around the nickel-gold (Ni-Au) coated solder spheres of BGA packages by becoming a mechanical diffusion barrier during socketing. This action allows more stable contact between the socket paddles and the gold surface, which provides mechanical reinforcement and extends the lifetime of the BGAs. Research results indicate that Georgia Tech’s polymer collars contribute to the formation of strong, thermodynamically stable solder joints. Also, the height of the spin-coated polymer collars can be tailored to the relevant application.

- Extend product lifespan: Increasing the stability of the contact between socket paddles and the Au surface allows for the BGAs to be in use longer

- Stability: Adding the mechanical reinforcement of the polymer collars allows for stronger thermodynamically stable solder joints

- Simple manufacturing: Spin coating the polymer onto the package is a simple manufacturing process.

- Microprocessors in the electronic industry

- Computer electronics for the automotive industry

BGAs have previously been limited to surface-mount applications primarily due to the lack of BGA-compatible production sockets and the fact that socketing applications required separate design and manufacturing. Recently, the compatibility of BGA interconnection system with socketing and surface mount technology (SMT) applications has improved; however, the BGA interconnection has had its own challenges with thermal aging reliability. Early research indicates that the Georgia Tech spin-coated polymer collars have remarkable potential to increase both reliability and joint strength for BGA packages, leading to greater usability in socketing application.

How It Works

When the tin-bismuth-silver (Sn-Bi-Ag) solder is left uncontrolled during socketing of the Ni-Au-coated spheres at high temperatures (80 to 120 °C), the solder spreads all over the sphere and shrinks the surface availability of gold at the top, where the ball-attach joint is located. Incorporating Georgia Tech’s polymer collars results in a lower rate of solder diffusion, which allows more stable contact between the socket paddles and the gold surface, extending the lifetime of the BGAs.

Schematic of polymer collar formation process