The SATURN self-powered acoustic sensor is thin, flexible, easily manufactured and, when deployed, converts everyday objects and physical surfaces into microphones. Developed by researchers at Georgia Tech, the SATURN microphone uses a triboelectric nanogenerator to transform vibrations into an electric signal without applying an external power source. The simple two-layer design optimizes the microphone’s sound quality in terms of acoustic sensitivity, frequency response, and directivity, offering improved audio performance compared to similar passive and active microphones.

The SATURN system communicates audio information via analog backscatter using simple circuitry consisting of a printed, flexible antenna and a transistor. Using radio backscatter, SATURN's sensed data is passively transmitted to remote computers, alleviating the need for batteries or any wired power for the material itself.

In addition, by harvesting power from environmental sounds, the SATURN system can flip a bit in a non-volatile memory cell to record the occurrence. Recorded bits can be read later as well as reset using a passive radio-frequency identification (RFID) interrogation system. SATURN can also power longer range radio transmitters to enable real-time alerts for sounds that exceed a certain threshold. For example, the system could store power from sound events lasting several seconds until it has enough to enable a 915 MHz backscatter transmission to the receiving antenna, announcing the event. As long as the event continues to occur, the SATURN system can transmit alerts every few seconds to a remote monitoring station.

The SATURN microphone can be deployed on a variety of surfaces, enabling new opportunities for audio sensing over large indoor and outdoor areas—both for mobile and stationary objects. The SATURN microphone may also enable battery-less remote sensing for acoustic events, which has potential applications in controlling noise pollution, enhancing workplace safety, environmental monitoring, and increasing military situation awareness.

- Lower cost: The SATURN microphone’s simpler and less expensive fabrication technique results in lower overall costs.

- Better performance: The microphone geometry, attachment methods, and size and spacing of holes are optimized to maximize the recovery of sound and generation of power. This results in better performance compared to commercially available microphones of this type, recovering sound up to 5,000 Hz.

- Versatile: Its thin, flexible, and passive form make it configurable to a large number of applications.

- Reproducible: Its fabrication method produces devices with consistent performance.

- Ambient noise monitoring

- Noise pollution (e.g., airports, construction sites, concert venues, mining)

- Workplace safety (e.g., noises exceeding safe sound thresholds for humans)

- Environmental monitoring (e.g., landslides, avalanches, polar ice movement)

- Military situation awareness (e.g., monitoring movement of tanks, troops, exploding ordnance)

- Smart home control

- Interaction with objects for voice-activated control

- Localization of sound sources

Previous triboelectric-based acoustic energy harvesters focused on maximizing electrical response at the natural resonant frequency. Nanostructure designs based on a ferroelectric nanogenerator have also been explored to make flexible acoustic sensors, actuators, and energy harvesters. These technologies rely on expensive and skilled fabrication techniques that make them costly to manufacture. Georgia Tech’s new SATURN microphone design costs less to fabricate, has a wider acoustic range, and has reproducible performance.

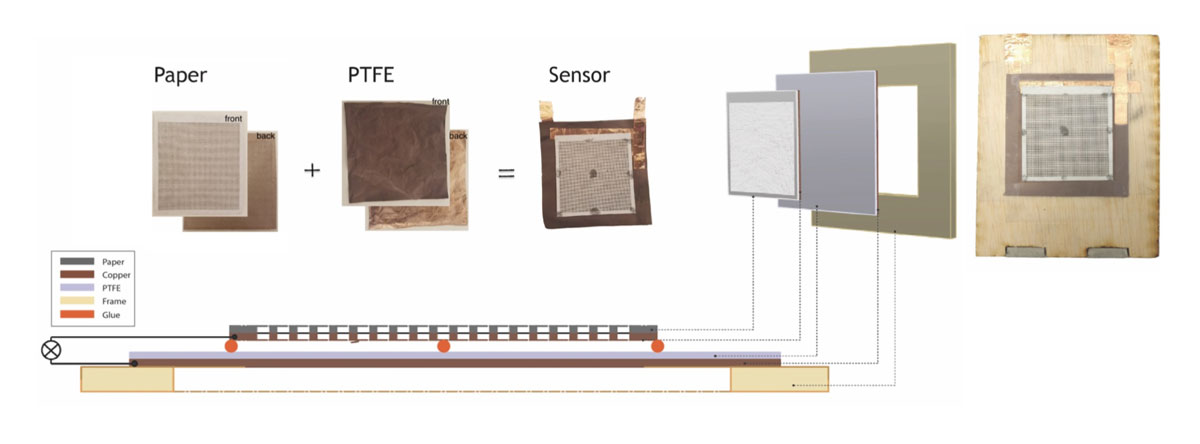

Structural design of SATURN Microphone consisting of copper coated paper and PTFE

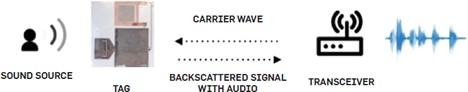

Self-sustainable sound sensing and communication architecture using SATURN and analog backscatter technique.

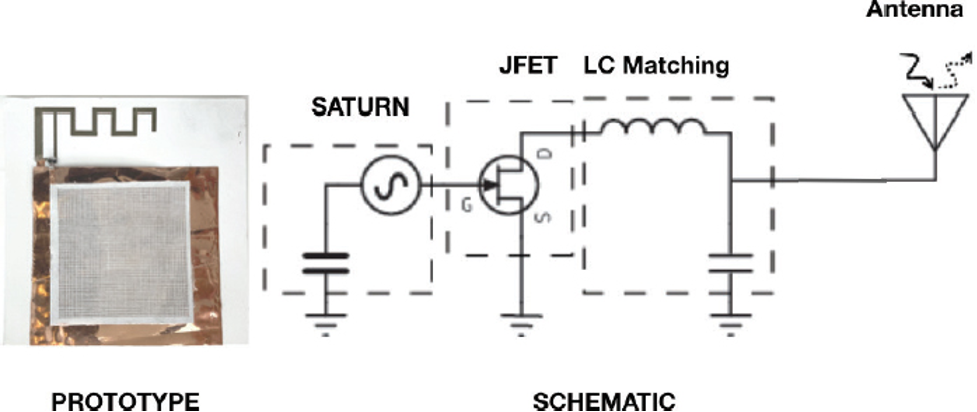

Tag consisting of simple circuitry—SATURN sensor connected to printed antenna using a JFET and an impedance matching circuit.

SATURN is flexible and can be made in different shapes and sizes, allowing instrumentation of everyday objects such as a soda bottle, shirt, and paper crafts.