This novel next-generation zinc-halogen aqueous flow battery uses a hollow fiber-based geometry that enables ultra-high power density while eliminating the need for bipolar plates. Designed by researchers at Georgia Tech, the tubular geometry of the ion-exchange membrane serves as the flow distributor and enhances the rate of ion transfer. The design eliminates extra battery parts to decrease cost while increasing the membrane surface area to increase power density.

The Georgia Tech researchers also created an in operando visualization platform, which allowed them to visualize the in situ dynamics at the surface of the bromine (Br) cathode in the zinc-bromine (Zn-Br) battery. They determined that N-methyl N-ethyl pyrrolidinium bromide (MEPBr) complexes with Br2 to form a second phase, which decreases its solubility. The resulting electrolyte and membrane uses zinc iodide (ZnI2), which has high energy density, high power density, and fast kinetics.

This in operando visualization platform is easy to set up and can be adapted to analyze other electrochemical systems that are sensitive to vacuum, electron beam, or X-ray, such as lithium-sulfur (Li-S) batteries.

- Higher power density: This design has achieved ultra-high power densities of 630 W/Ldevice (charge) and 170 W/Ldevice (discharge), compared to existing flow battery designs that achieve only 500 W/Ldevice (charge) and 90 W/Ldevice (discharge).

- Ultra-high current density: The design has achieved current densities of >300 mA/cm3 per device.

- Dramatically lower cost: The elimination of parts reduces fabrication costs by 90%. Cost is ~$330 rather than ~$4,400.

- Scalable: The universal tubular design is highly modular and can be easily scaled up.

- Versatile: The design can be applied to various common redox couples such as zinc, vanadium, and anthraquinone-based flow batteries.

- Flexible: The high design flexibility allows the flow battery to be directly used for in operando analysis.

- Flow batteries

- Load balancing for residential to grid-level energy supply

Electric flow devices have been widely used as a renewable energy storage tool. Flow batteries convert sustainable resources to electricity and, because their energy and power can be scaled separately, they can serve energy demands ranging from grid-level systems to handheld devices. This offers promising intermediate energy storage. While significant progress has been made to improve flow battery energy density, the classic flat-sheet membrane-based flow battery has a high system volume, which lowers the power density, and a high cost. Georgia Tech’s hollow fiber-based flow battery design solves those problems.

Because there was no diagnostic tool for time-resolved, microscopic understanding of Br cathodes, the researchers developed an in operando microscopic visualization platform for the electrochemical formation and decomposition of polybromides on electrodes. The visualization provides dynamic information, which provides diagnoses to electrochemical systems, verifies previous hypotheses, and uncovers new details.

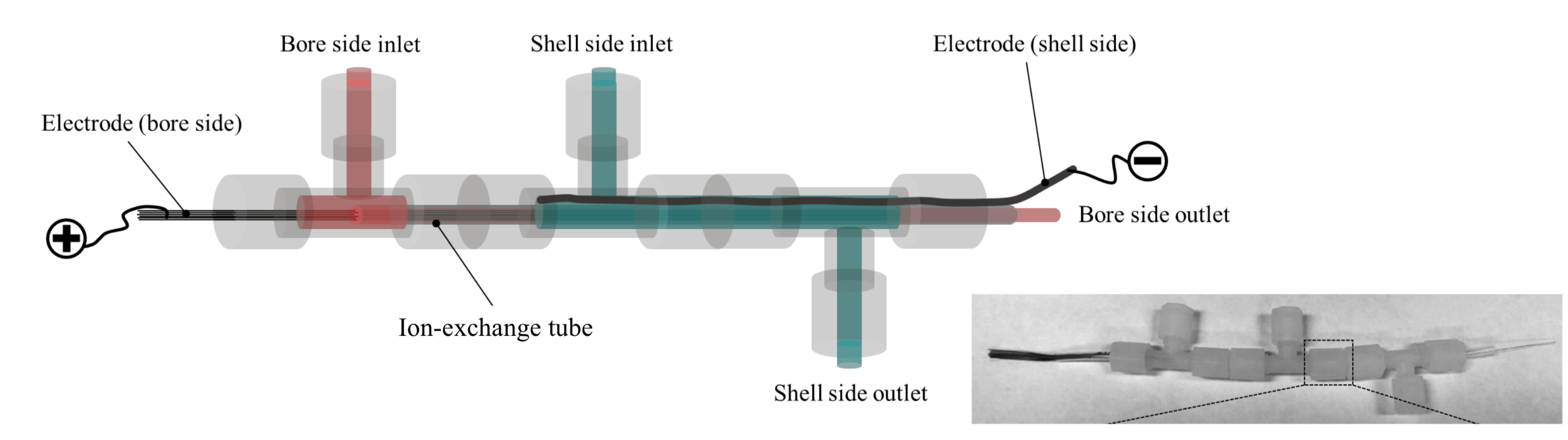

Tubular design of the power module.