With major aerospace companies working on development of electrical aircraft that use cryogenic fuels, the need is growing for cryogenic conductors with superior gravimetric power density. Current commercially available superconducting wires support very high current densities and conduct electric direct current at zero losses. However, they suffer from drawbacks including geometrical constraints, high manufacturing costs, and difficulty being manufactured in long lengths. Copper conductors do not have these drawbacks, but they are heavy. Alkali metals such as lithium offer more conductivity per unit mass compared to copper but have high chemical reactivity.

Cladding lithium with copper enables its use as a conductor in cryogenic and other conditions

A good balance between properties can be found in copper-clad lithium (CuCLi) conductors. Because lithium exhibits improved electrical performance at low temperatures, higher conductivity per unit density values can be achieved, making this invention crucial for applications with high gravimetric power density needs (e.g., aerospace). CuCLi wires are lightweight, versatile, and cost-effective and can be used in cryogenic conditions for aircraft and high-frequency applications.

- Higher current density per unit mass: Alkali metals such as lithium exhibit good electrical conductivity at low mass density, especially under cryogenic conditions.

- Round wires at long lengths: CuCLi wires have an advantage over superconductors in that they can have a circular cross section and can be made at long lengths, making them suitable for windings in motors, generators, and transformers.

- Complex geometries: Unlike superconductors, CuCLi parts can be made to any geometry, making them suitable for cable accessories such as terminations, clamps, feedthroughs, and connectors.

- Versatile operating conditions: CuCLi conductors can operate over a wider range of temperatures, current densities, and magnetic flux densities than superconductors. While the losses increase with higher temperatures, current densities, and magnetic flux densities, there is no critical point at which they stop working.

- Standard tools: Cladding the lithium core with copper enables the billet to be drawn using standard wire-drawing techniques and tools, while protecting the core from chemically reacting with the environment. It also allows the manufacturing of CuCLi litz wires, which are suitable for high-frequency operation.

- Low cost: Lithium is abundant and inexpensive.

- Aerospace industry

- Future electric aircraft that use cryogenic fuel

- Satellites

- Spacecraft

- Defense industry

- Power transmission and distribution

- Switching, semiconductor, and superconductor devices

- Cryogenic power electronics

- Inductor and transformer windings

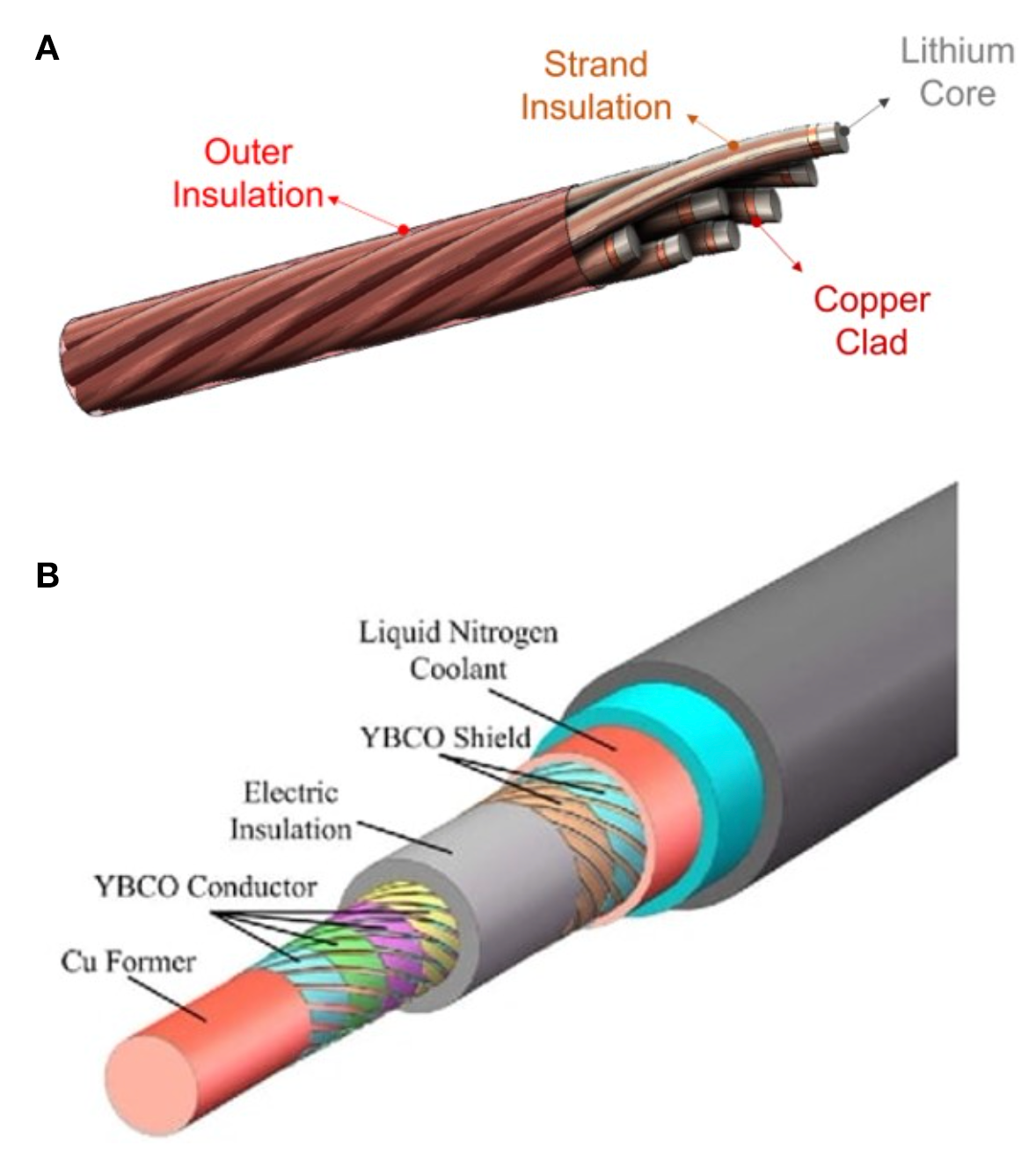

Comparison between structures of (a) CuCLi cable (Litz strand) and (b) superconducting cable using yttrium barium copper oxide (YBCO) conductor

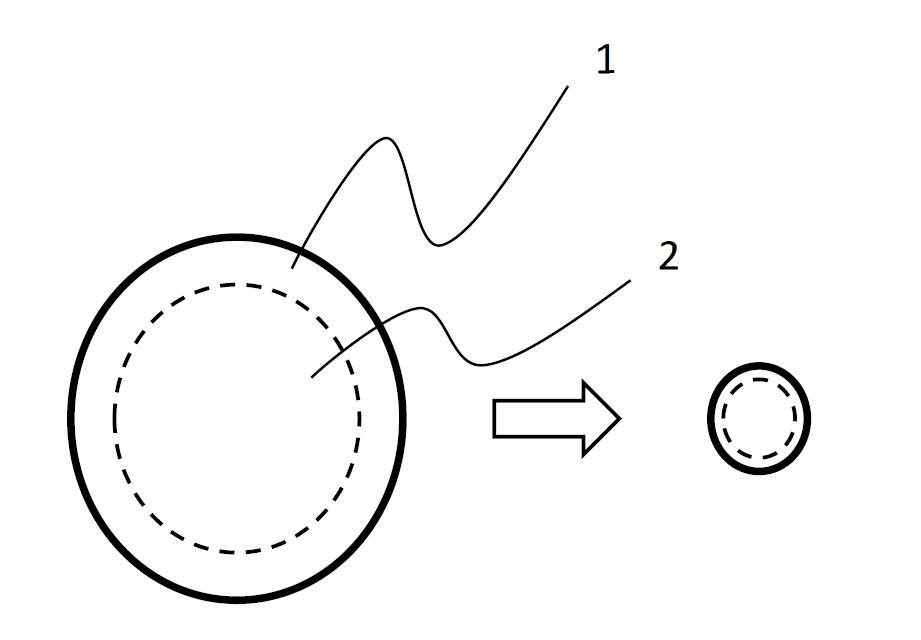

A schematic illustration of a wire with a small cross-sectional area and long length, as processed via calendaring, drawing, and annealing. The outer conductor area (1) includes malleable, ductile metal, wherein the metal can be copper, aluminum, or silver. The inner conductor area (2) includes metal of high conductivity-to-density ratio, wherein the metal can include lithium, calcium, or sodium.