This technology offers a simple and robust method for integrating parallel electrodes into microfluidic devices that are manufactured using soft lithography. It overcomes the challenges associated with the typical planar arrangement of electrodes for electrical sensors—constricting electrodes to a plane creates non-uniform electric fields and also makes them difficult to scale into a more complex design. Georgia Tech’s parallel arrangement also reduces electrical resistance, demonstrates a higher sensitivity to cell signals, and is suitable for device layouts of various complexities.

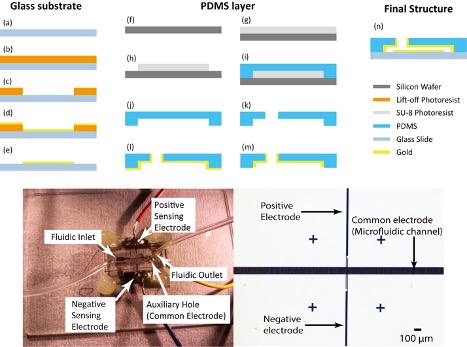

Georgia Tech’s method fabricates electrodes on a glass substrate using a lift-off process and also places counter-electrodes over the plastic walls of the microfluidic channel. A gold-coated polydimethylsiloxane (PDMS) microchannel is activated along with the glass substrate in oxygen plasma, aligning and bonding them. A conductive epoxy-coated wire is then added. This process is significantly more straightforward than current similar fabrication methods but is still compatible with soft lithography.

- Sophisticated: Advances the integration of electrical sensors on microfluidic devices with a simple, approachable solution

- Sensitive: Demonstrates a higher signal sensitivity than electrodes in a typical coplanar arrangement

- Adaptable: Allows for greater layout flexibility because of its straightforward fabrication process

- Biotechnology

- Clinical and lab settings

- Environmental monitoring

- Industrial purification

Electrical sensors are commonly used in microfluidic devices for tasks such as counting, sizing, and electrical characterization of suspended micro/nanoparticles. Typically, electrodes are placed on the floor of microfluidic channels in a coplanar arrangement. Though parallel electrode arrangements allow for more uniform electric fields and provide more flexible integration, their use has been limited because of the complexity of their fabrication. This Georgia Tech innovation provides a straightforward solution to include parallel electrical sensors in microfluidic devices, leading to more reliability and efficiency for lab-on-a-chip settings.

To see more technologies by Dr. Sarioglu and his team, please click here.

A schematic diagram of the parallel electrode fabrication method and a photo of the final device, showing methods for the glass substrate and the PDMS layer as well as the final bonding for the full device.