This microelectromechanical system (MEMS) innovation is the industry’s first demonstrated, fully integrated piezoelectric standalone frequency comb. Used in MEMS frequency synthesizers for precision time metrology, molecular spectroscopy, and wavelength multiplexing, Georgia Tech’s device builds on widely used optical frequency combs with a phononic counterpart that involves coupling two or more resonators. The innovation provides the ability to tune frequency spacing as well as bandwidth and center frequency in a fully integrated platform and simplified design compared with leading alternatives.

The resonant-based MEMS frequency combs are driven with a single-tone pump. Phase-coherent spectral lines are generated and tuned based on non-degenerate parametric pumping and by taking advantage of mode coupling between two resonant modes in the same acoustic cavity. It is suitable for replacing integrated complementary metal-oxide-semiconductor (CMOS) MEMS configurations as the building block of oscillators, decreasing the footprint and shot noise associated with electronics circuitry. The novel sensing scheme with two or more high-quality resonant modes also provides significantly higher sensitivity compared with traditional frequency-shift detection schemes.

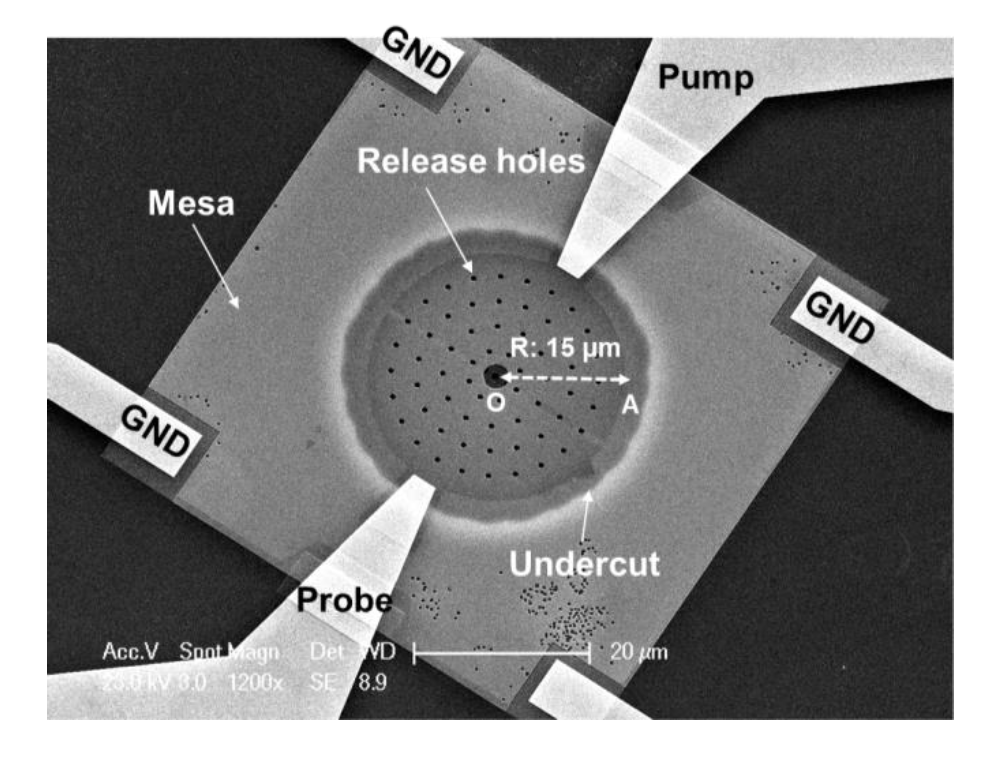

- Compact: Provides a fully integrated package with a smaller footprint (30 μm x 30 μm) compared with CMOS-MEMS configurations

- Robust: Offers higher sensitivity and enhanced detection limit compared with the previous state of the art

- Low noise: Lowers shot noise levels associated with electronics and MEMS circuitry by eliminating the need for circuitry like electronic amplifiers

- Streamlined: Reduces electronics configuration complexity by taking advantage of two resonant modes within the same acoustic cavity

Georgia Tech’s innovation is broadly applicable to MEMS configurations, in particular:

- Frequency synthesizing

- Dual-mode sensing

- Precision time metrology

- Molecular spectroscopy

- Wavelength multiplexing

Mechanical resonators are passive components, typically integrated with an energy-restoring element such as an electronic amplifier, in order to sustain oscillation in a feedback-loop system. The interface of MEMS circuits is particularly challenging as the size of the sensor shrinks, but lowering its footprint is a constant effort because scaling of the resonator is needed to increase the sensor sensitivity to absorbed mass. Unfortunately, this results in larger motional impedances, which make interfacing with electronic devices challenging.

Georgia Tech’s innovation addresses these issues by bypassing the use of electronic amplifiers as the energy-restoring element in favor of a single-tone pump with a frequency equal to the sum of the frequencies of two acoustic modes within the same resonator. The resulting advantages make the technology an ideal replacement for CMOS-MEMS oscillator configurations.

This image shows a standalone AlN-on-Si micromechanical resonator. The diameter of the circular membrane is 30 μm. The release holes are used to isotropically etch the buried oxide layer with HF.