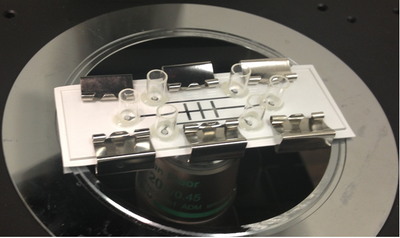

Researchers at Georgia Tech developed a microfluidic device that allows the study of chemotaxis and even detection of live and viable bacteria. A combination of microfluidic channels, nitrocellulose membrane, and chemical gradients allows for the analysis of bacterial movement and the detection of viable bacteria quickly, directly, and cheaply. The device can create a linear chemical gradient in less than 20 minutes. Importantly, the stability of this gradient is independent of the inflow of fluid. A positive (nutrient) or negative (noxious chemical) stimulant can then be introduced and the motility response of any live bacteria present can be detected and directly observed. Due to the designs of the chamber, movement of bacteria is solely caused by chemotaxis and not the simple flow of fluid.

- Ease-to-use – Sensor design is simple and device is self-powered

- Versatile – Allows detection of: NOx, SOx, H2S, CH4, CO, CO2, H2O, HCL, NH3, PH3, toluene, and mercaptons

- Reliable – Design allows analysis with low power consumption at high temperatures

- Innovative – Self-calibrating sensor system that includes wireless telemetry

- To study chemotaxis

- Detection/presence of live bacteria

- Food safety industry

- Oncology

Chemotaxis is the process by which bacteria guide their movement in their environment. Using complex signaling pathways, bacteria can propel themselves to nutrients or away from toxic conditions. Beyond understanding a basic mechanism of bacterial propagation, understanding chemotaxis can help better understand and perhaps prevent human disease. Human pathogens use chemotaxis to enhance their survivability and proliferation, and ultimately cause disease. In the case of Salmonella, chemotaxis can be used to actually invade beyond the surfaces of food. Studies have shown Salmonella bacteria use chemotaxis to move beyond the surface and penetrate lettuce leaves, thus rendering standard food decontamination techniques and detection useless. Unfortunately, many current methodologies for bacteria detection, particularly pathogens in the food safety industry, are costly, time intensive, and do not always indicate the presence of live, viable bacteria.