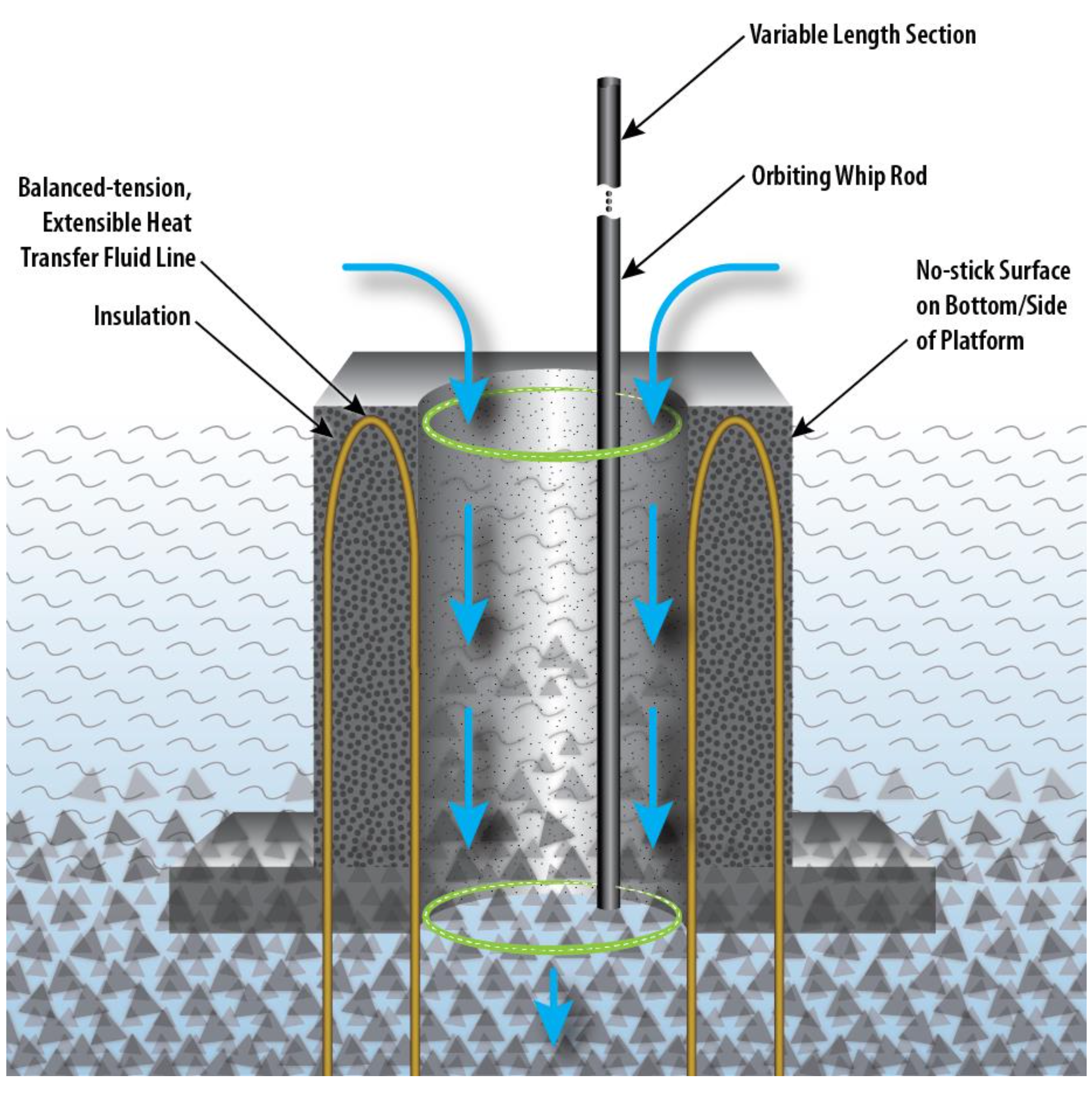

Using a buoyant platform that passively floats above solid phase change material (PCM) but stays below the liquid PCM state, this innovation improves and simplifies thermal management for energy storage, recuperative processes, environmental controls, and more. This technology developed by Georgia Tech improves thermal discharge (even for types of PCMs that are more difficult to solidify) by progressively moving the heat sink through the liquid PCM region and incorporating agitation. It uses extensible refrigerant lines to prevent the common problem of growing thermal resistance when path lengths increase between the phase-change front and the heat sink. Liquid PCM is passively moved through the solidification process with minimal or no thermal resistance (or contact resistance gaps) forming on the heat sink.

- Enhances solidification: Incorporating highly localized agitation via a stirring whip rod, this technology seeds solidification to improve this often-arduous phase of PCM thermal cycling.

- Prevents scale build-up: This technology reduces the instance of sheets of solid PCM forming on the heat sink. The high-frequency, extensible whip rod orbits around the passageway to facilitate nucleation (creating improved solidification), while preventing scale build-up on the interior passageway surfaces.

- Customizable: The structural design allows the platform to be tailored to the effective density of the PCM material, enabling it to stay between the liquid and solid phases.

- Versatile: The innovation focuses upon the discharge phase of PCM thermal cycling, but it is readily compatible with the charging/melting phase of PCM thermal management.

- Flexible: The system can be retroactively engineered into existing PCM applications.

- Thermal energy storage

- Recuperative process thermal management

- Advanced HVAC systems and environmental controls

- Cold supply chain

- Renewable energy systems

- Possible device-level thermal management

This vertical cross-sectional concept of Georgia Tech’s buoyant platform during thermal discharge illustrates how liquid PCM flow is induced in a relative downward manner as a whip rod facilitates solidification. The platform passively elevates to remain above the bulk solid/slurry front, given engineered buoyancy. Solid PCM is indicated by the triangles shown collecting at the bottom, and liquid PCM is indicated by the wavy lines toward the top.