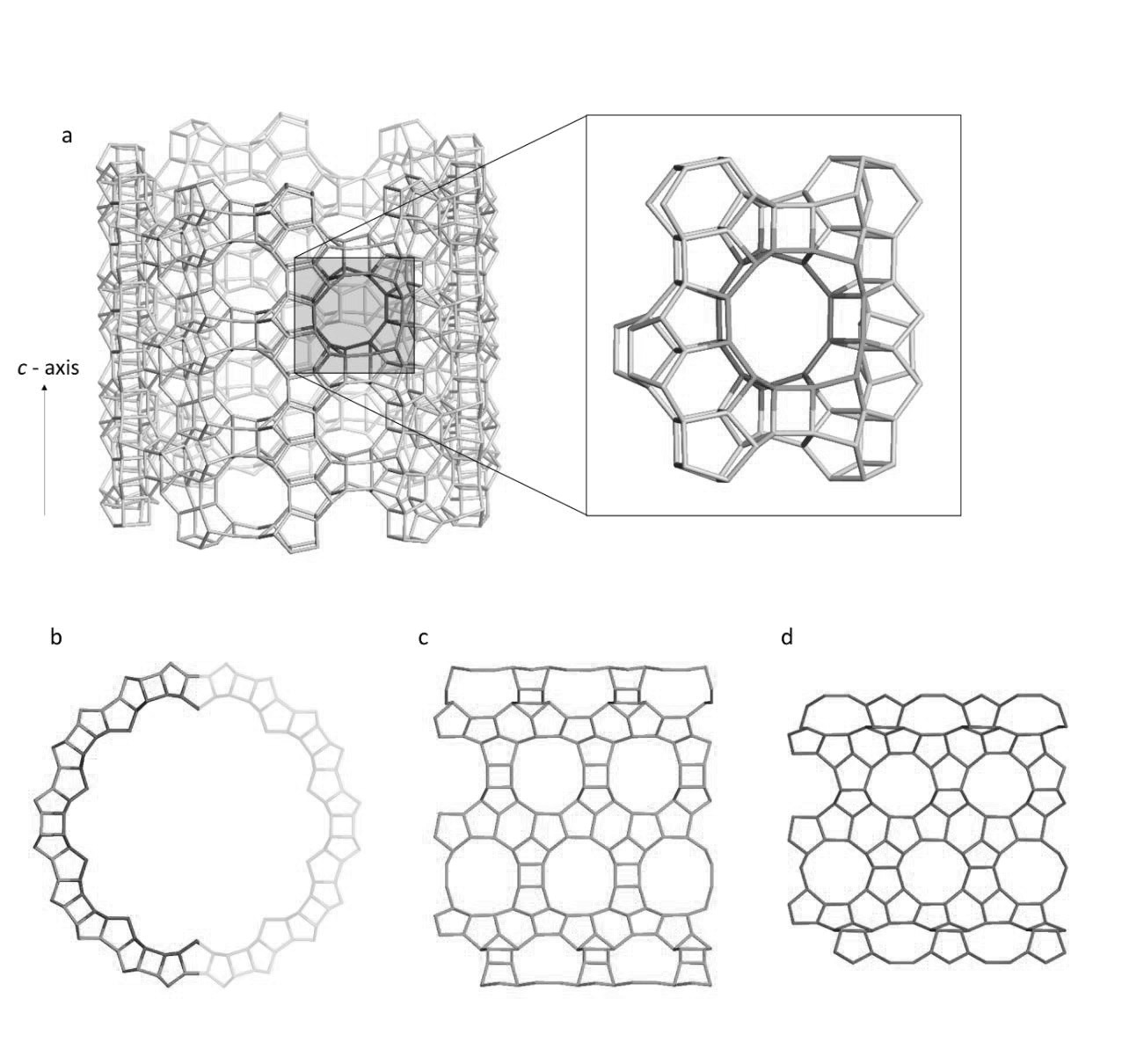

This innovation enables the formation of one-dimensional zeolite nanotubes, or single-walled nanotubes consisting of a microporous zeolitic wall enclosing one central mesoporous channel. It derives the nanotubes from aluminosilicate material composed of hollow tubes (approximately 5 nanometers in diameter) with a porous wall that has a zeolite structure. The wall is perforated by well-defined nanopores that, in conjunction with the material’s tubular shape, allow for easier flow into and out of the structure.

This Georgia Tech technology is designed to provide the next generation of hierarchical zeolite materials by combining microporous zeolites and mesoporous materials. The nanotubes are perforated with micropores and also maintain a mesoporous structure in their central channel without collapsing, an advancement of the current state of the art. In this way, the material could allow for new types of chemical processes that would not be possible with conventional zeolites.

- Streamlined: Allows for faster access into and out of zeolite pores without compromising key characteristics of conventional zeolites

- Advanced: Supports a single central mesoporous channel even after calcination of the organic structure directing agents

- Robust: Consists of both micropores and mesopores with the potential to enable a variety of separation and catalytic properties.

These zeolitic nanotubes may enable a wide range of advances in chemical catalysis and chemical separation processes, particularly in industries that require the following applications:

- Petrochemical production

- Biomass conversion

- Thermal energy storage

- Oil-water separation

- Hydrogen (H2) production

- Radionuclide removal

- Exhaust post-treatment

- Carbon dioxide (CO2) capture and conversion

Zeolites are used widely in a variety of chemical separation applications—particularly in the petrochemical industry—because their ordered microporous structure makes them size- and shape-selective catalysts and adsorbents. There has been a growing interest in the synthesis of hierarchical zeolites that include mesopores as well as micropores. The interconnected nature of the micropores and mesopores allows for the diffusion of bulky molecules to the zeolite interior and creates surface sites with new adsorptive and catalytic environments.

Construction of the nanotube shown only in tetrahedral atoms, built from an outer and inner layer