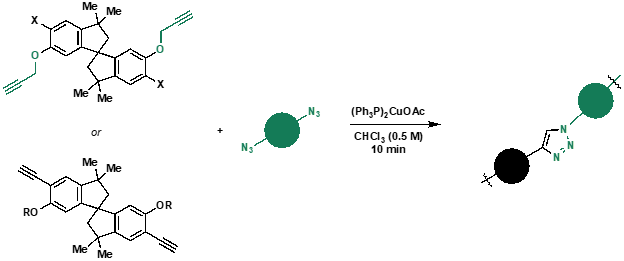

This innovation establishes a method for the large-scale fabrication of high free-volume polymers with high molecular weights using structurally kinked monomers. The polymers are made using the copper-catalyzed azide-alkyne cycloaddition (CuAAC) reaction and monomers with dialkyne and diazide functional groups, one or more of which contains a spirocenter. This process produces long polymers suitable for liquid or gaseous membrane-based separation techniques used in hydrocarbon refining and water purification.

The resulting polymers can be manufactured to have any desired form, including thin films or hollow fibers. In some forms, polymers can take advantage of solid-phase and structural supports to provide intrinsic microporosity and high chemical stability, improving their separation performance. These solution-processable polymers have the potential to greatly expand the design space of such industries as thermoplastics, coatings, adhesives, and packaging.

- Scalable: Uses simple chemistry and eliminates production steps to enable large scale polymer manufacturing

- Solution-processable: Permits the development of a variety of membrane morphologies including dense flat sheets, thin film composites, and hollow fibers

- High chemical stability: Results in stable structures able to withstand exposure to solvents and other chemicals, enabling stable separation performance and industrial application

Membrane-based separations used in:

- Hydrocarbon refining

- Water purification

- Gas separation

- Energy production

Polymeric membranes have emerged as a possible energy-efficient molecular separation platform relative to traditional energy-intensive processes such as distillation. Membranes that combine porosity and rigidity can allow for high permeability and good selectivity. Polymers of intrinsic microporosity (PIMs) are a unique polymer class that combine solution processability and solid-state microporosity characteristics in the same material. Current approaches for such polymeric membranes can be limited by solution processability, ability to maintain constant pore sizes in solvent, limited tunability of pore sizes, and limited functional group tolerance.

Improvements in polymeric membrane technology could expand the design space of numerous industries, such as hydrocarbon refining, water purification, gas separation, and energy production.

General reaction scheme of a spirocycle-containing dialkyne reacting with a diazide in the presence of a Cu(I) catalyst to generate triazole-linked polymers