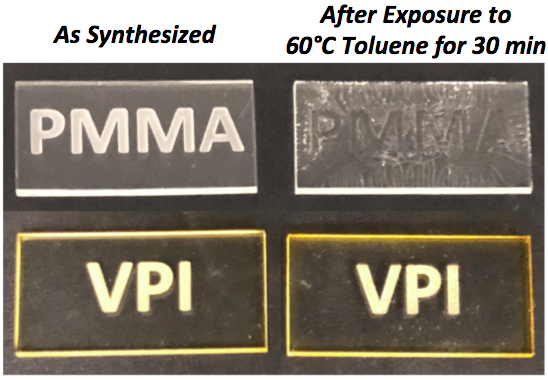

Inventors at Georgia Tech have advanced a process called Vapor Phase Infiltration (VPI) that requires only a single exposure cycle to convert microns of polymer into a hybrid material. VPI can chemically modify a variety of polymeric materials in a variety of form factors using low-pressure, highly reactive gases. This technology utilizes the following steps: sorption, diffusion, and entrapment. During sorption, a gaseous metalorganic precursor is dissolved into a polymer. The precursor then migrates during the diffusion step. In entrapment, the precursor is immobilized through reaction or steric hindrance.

- Cost reduction – cost is reduced due to technique simplification

- Efficiency – technique has no requirement for repeated cycling

- Flexibility – VPI can be applied at any stage in production processes

- Increased reliability – chemical properties are more stabilized

Manufacturing for:

- Polymer Membranes

- Polymer Fabrics / Textiles

- Polymer Films

- Polymer Foams

- Bulk Polymers

- Polymer Powders / Microspheres

Atomic Layer Deposition (ALD) is a surface-controlled process that results in the deposition of thin films one layer at a time. Each atomic layer that is formed by this sequential process is a result of saturated surface-controlled reactions. In ALD, increasing processing volume presents significant challenges to the fluid dynamics in the chamber, with unpredictable effects on the quality of the film deposition. Additionally, long cycle times and the layer-by-layer nature of ALD result in slow deposition rates. There is a need to develop a more efficient process to modify polymeric materials.