This method for removing large side chains from conjugated polymers (CPs) can significantly increase the electrical and thermal conductivity of polymer films used in myriad applications ranging from batteries to advanced display technologies. Utilizing post-processing hydrolysis for side chain removal, Georgia Tech’s innovation can be applied to high-performance polymer repeat unit structures. Doing so yields an average conductivity of more than 450 siemens/centimeter (S/cm)—the highest value of any non-PEDOT dioxythiophene-based material. The method even outperforms any currently available oligoether/glycol-based CP system, making it ideal for applications requiring highly conductive materials.

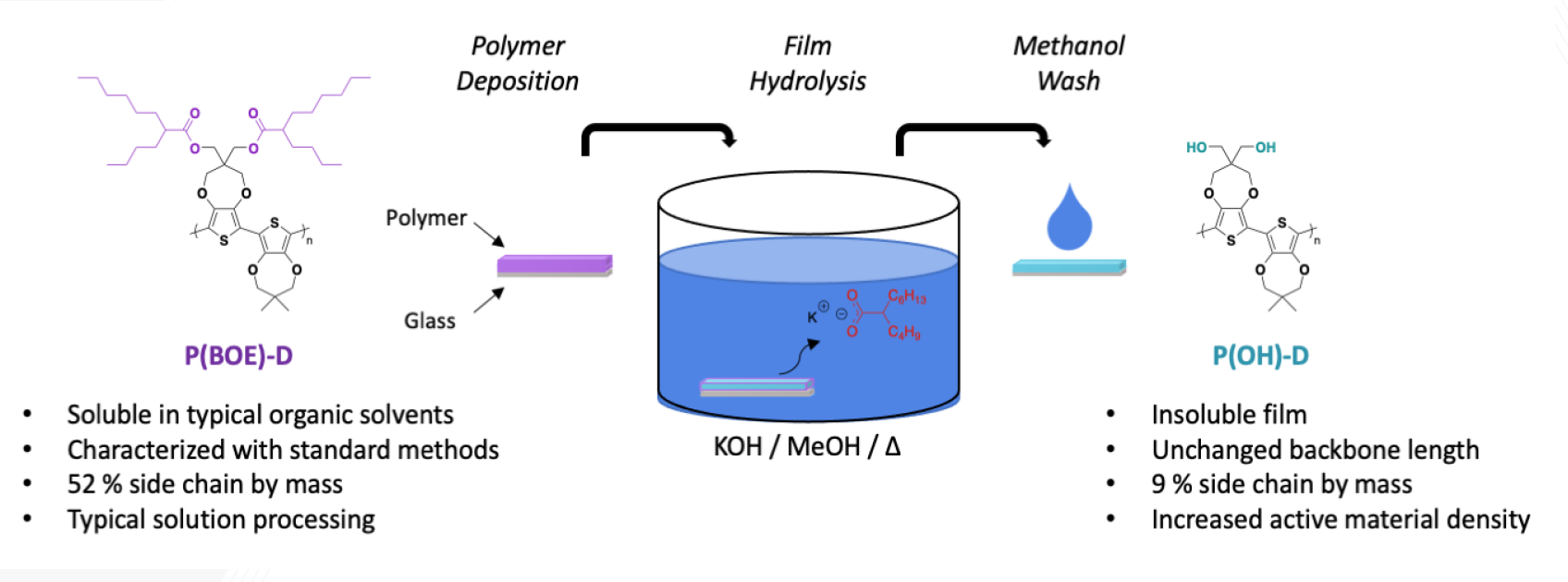

Georgia Tech’s method involves preparing polymer films by using any typical method and then immersing them in a solution to hydrolyze the side chains and remove them from the film, rendering it insoluble. Solution doping is then performed using an oxidant or reductant. Following this procedure, the polymer films demonstrate a significant increase in solid-state electrical conductivity compared with unhydrolyzed and doped polymer films.

- Advanced: Can increase electrical conductivity of doped polymer films by tenfold while decreasing the Seebeck coefficient from 46 μV/K to 18 μV/K, resulting in a doubling in thermoelectric power factor

- Robust: Demonstrates an increase in both in-plane and through-plane thermal conductivity upon hydrolysis

- Best-in-Class: Surpasses the S/cm value of any currently reported oligoether/glycol-based CP system

- Convenient: Enables polymers to be fully solution processed using roll-to-roll compatible methods while being studied using conventional methods

- Effective: Facilitates removal of side chains to not only increase conductivity but to also render the film insoluble—a beneficial attribute for electronic displays and other applications

- Economical: Employs side chains that are inexpensive and easier to use than those tested in other available scaled-up reactions

Georgia Tech’s innovation is broadly applicable to products and applications requiring highly conductive materials, in particular:

- Thermoelectric devices

- Bioelectronics

- Electrochemical devices

- Flexible electrodes

- Semiconductors

- Batteries

- Capacitors

- Display technologies

The development of electroactive CPs has become increasingly important due to their utility in numerous electrochemical and semiconductor devices. Side chains appended to the CP backbone for solubility and processability play a significant role in tuning the structural, redox, and electronic properties of the polymers. However, in order to solubilize the CP backbones, the side chains must be relatively long and/or branched (typically with chiral centers) to induce many degrees of conformation freedom. Ultimately, such side chains reduce the relative fraction of active material in the film, obstruct pi-pi intermolecular interactions, and compromise the conductivity and many other desirable properties of the material. Methods to reduce or remove side chains while maintaining processability may result in higher conductivity systems. Georgia Tech’s innovation directly addresses this need with a method for side chain removal that shows a significant increase in electrical conductivity.

An overview of the film hydrolysis used in Georgia Tech’s method for post-processing side chain cleavage