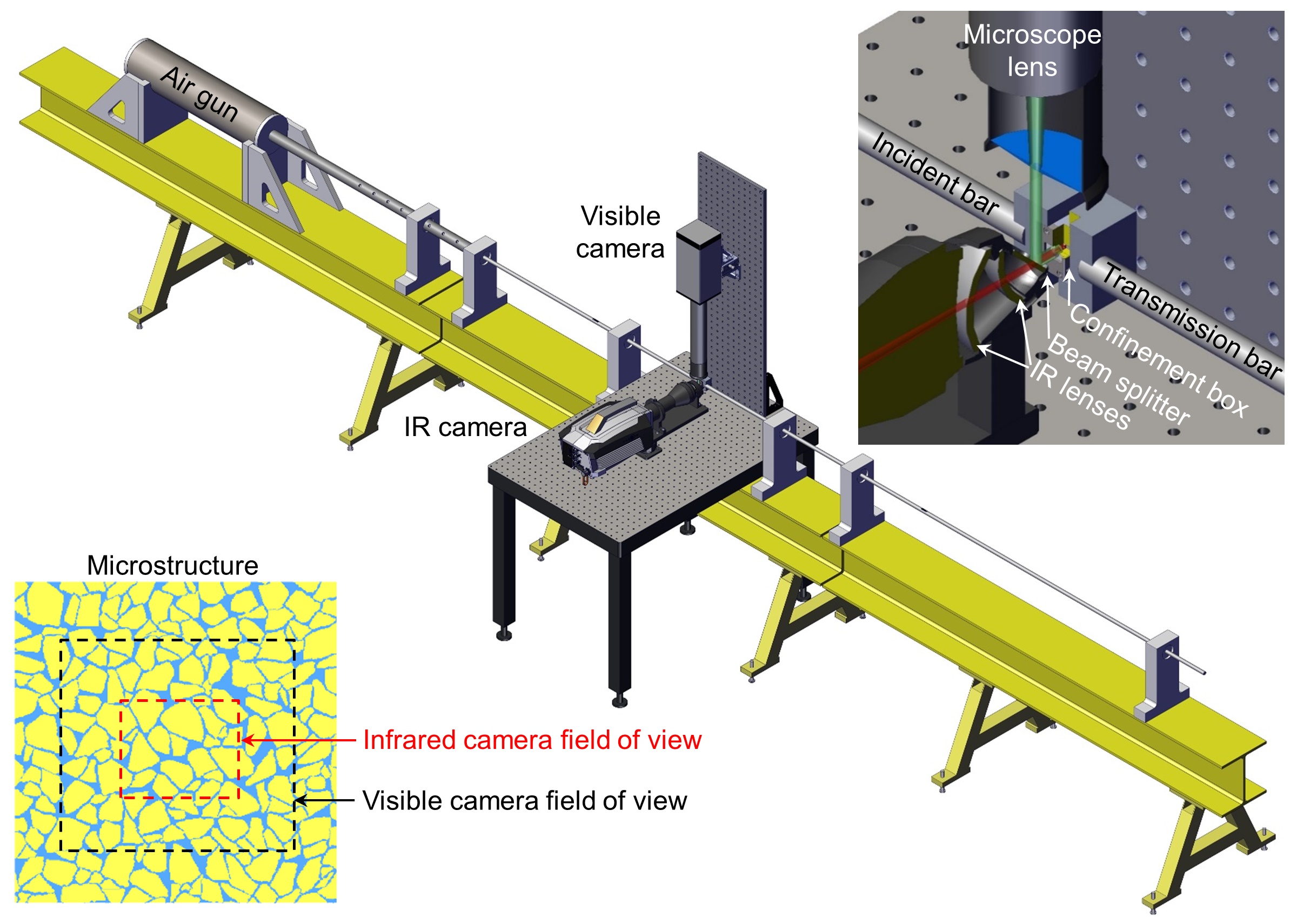

Inventors at Georgia Tech have developed MINTED, a system that captures a simultaneous time- and space-resolved recording of both deformation and temperature over the same microstructure area of a sample. This microscale in-situ imaging of dynamic temperature and deformation fields provides micron-level spatial resolutions and microsecond time resolutions by integrating a high-speed visible light camera and a state-of-the-art high-speed infrared camera. The data provided will give detailed first-time insight into the processes of fracture, friction, shear localization, and hotspot development in the microstructures.

- Simultaneous recording of small-scale temperature and deformation fields at high spatial and time resolutions

- Studies deformation, failure, and heating in a range of materials

- Analyzes/monitors heating and failure of MEMS devices, microchips, and circuit board

- Aerospace

- Automobiles

Measuring the deformation and temperature fields of mesoscale mechanisms at the microstructure level is important for proper evaluation and for validating models. Mesoscale mechanisms are responsible for the behavior of heterogeneous materials such as plastics, ceramics, and glass. Without this evaluation, materials are instable, may fail or even explode. Until now, there has been no method yielding deformation and temperature measurements simultaneously.