Georgia Tech inventors have created RFID tags comprised of components disposed on a flexible conformal substrate. The substrate are substantially transparent and opaque and the components are comprised of organic electronic components. Components and circuits are manufactured using thin-film deposition processes and by deposition of metal-containing inks using inkjet technology. One aspect of the invention comprises a radio frequency identification (RFID) transponder. The RF transponder is comprised of a substantially flexible, conformal substrate. Disposed on the substrate are one or more electronic devices including an antenna; a power source; a modulator; and a data/identification memory unit. The electronic devices are operatively coupled using one or more conductive circuits disposed upon said flexible, conformal substrate.

- Ultra-thin

- Highly flexible and conformable

- Long sheltimes and operation times

- Non-toxic

- On-vehicle radio-frequency (RF) automated toll system

- Homeland security

- Inventory

- Identification

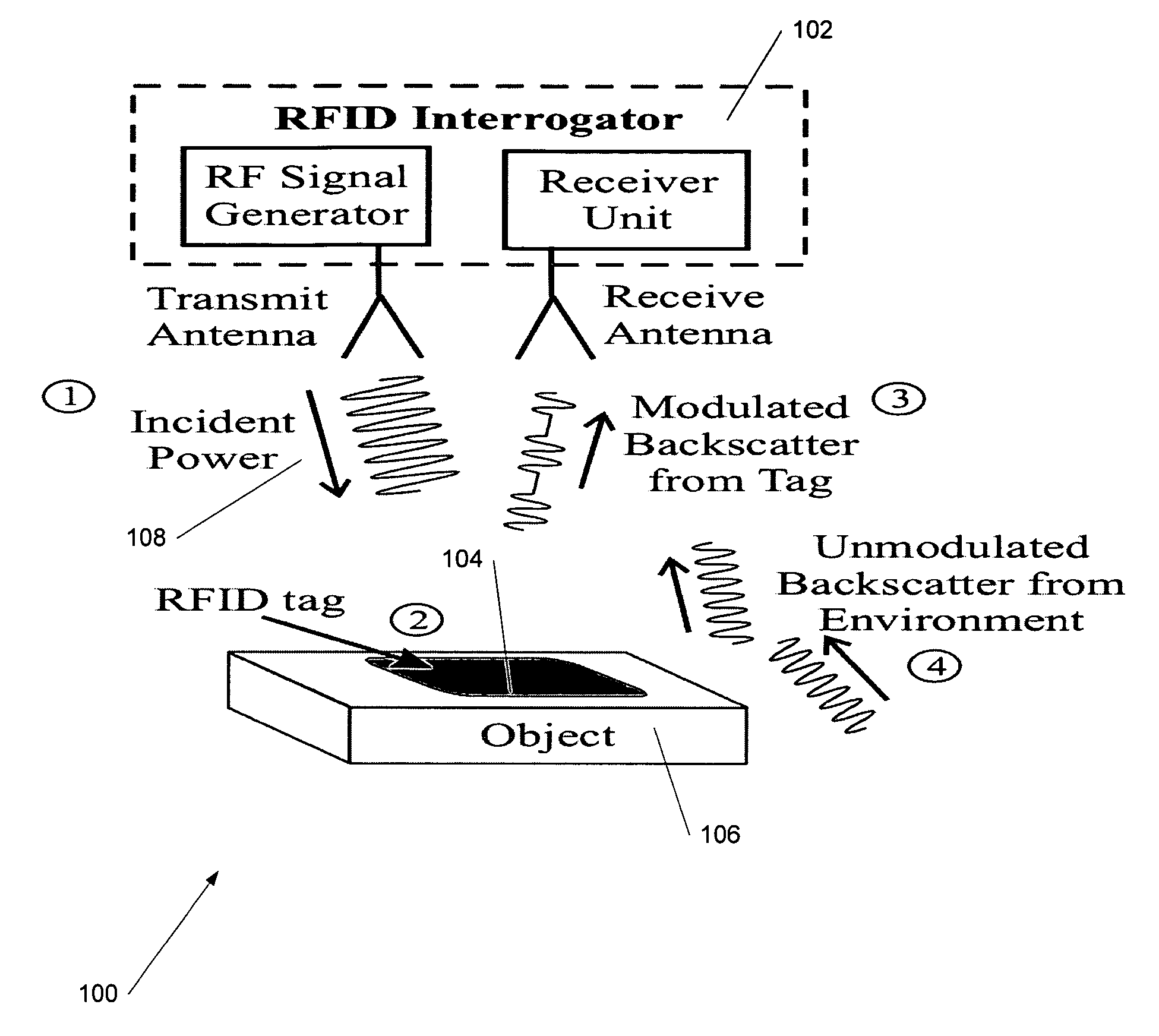

Radio frequency identification (RFID) provides a wireless link for automatic data capture. RFID systems include electronic devices called tags, and a transceiver that communicates with the tag. These systems communicate via radio waves that carry data. These data are stored in the tag and can be read by the transceiver.