This technology integrates an alkali metal dispenser with a micro-collimator to create a localized and collimated atomic beam of alkali vapor that can be reversibly exposed to air without degrading its properties. Rubidium vapor is produced through a reduction reaction in the alkali metal dispenser. The rubidium vapor thermalizes with the collimator plate before emerging through the etched holes in the collimator plate, which guide the atom flux forward and simultaneously moderate its velocity. Georgia Tech’s invention is designed to moderate the dispenser radiation so that the emitting surface and the rubidium vapor are both considerably cooler than the dispenser itself, enabling electronic components to be placed in close proximity.

This technology can be used in nanotechnology, integrated photonics, micro-electromechanical systems (MEMS), and chip-scale atomic clocks—applications where there is a need for integrating alkali vapor sources directly at the locations of specific on-chip elements. Current technologies result in broad angular distribution of the alkali vapor, which can degrade the signal-to-noise ratio as well as contaminate nearby electronic components. Further, current alkali dispensers do not moderate the radiative heat from the required high-temperature (550–850°C) chemical reduction reaction, which can also influence nearby electronic components.

- Precise: Reducing the “spread” of vapor via collimation can reduce potential signal-to-noise ratio degradation and avoid contamination of nearby electronic components.

- Simple: Generating a directed atomic beam from the dispenser can be achieved via integrated packaging.

- Cooler: Placing a spacer material between the dispenser and collimator creates a sealed gap that not only prevents leakage, but also allows the vapor to cool (via rapid thermalization with the collimator plate).

- Enabling: Moderating dispenser radiation allows for integration with electronic components in close proximity (e.g., chip-scale systems).

Any application where there is a need for integrating alkali vapor sources directly on-chip, including:

- Nanotechnology

- Integrated photonics

- MEMS devices

- Chip-scale atomic clock

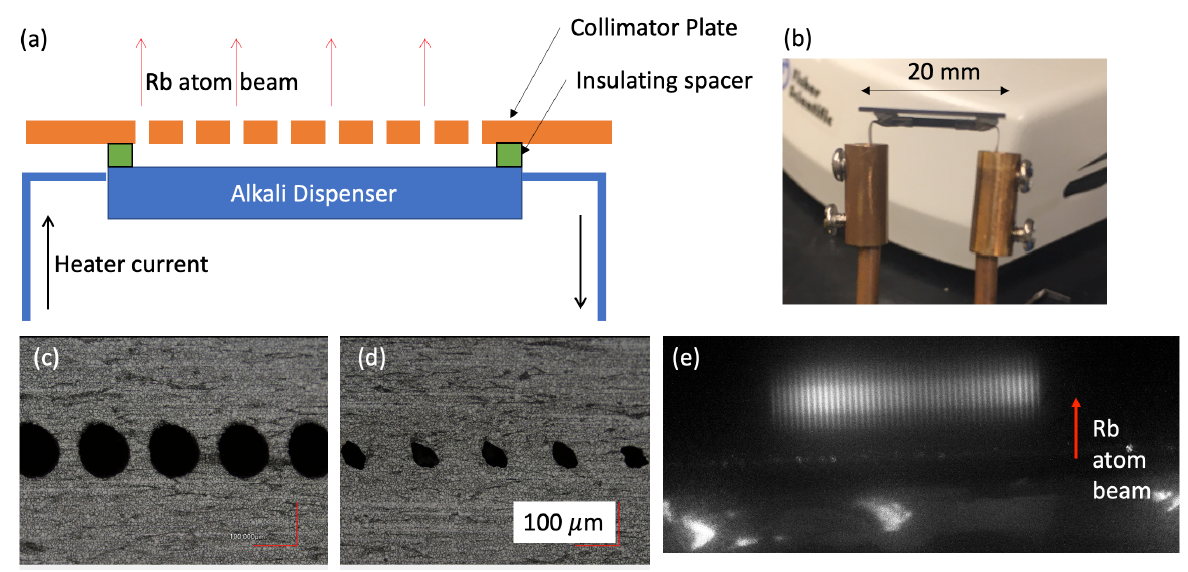

An alkali metal dispenser produces rubidium vapor through a chemical reduction reaction. The reaction occurs at high temperatures (550–850°C), and the resulting neutral alkali atoms are emitted into the surroundings as an undirected vapor. In Georgia Tech’s integrated alkali dispenser collimator, the emitted vapor immediately encounters a collimating plate with etched holes that guide the atom flux primarily in the forward direction; this plate simultaneously serves to moderate vapor velocity.

A spacer material in the form of high-temperature cement is placed between the dispenser and collimator to create a very small, 0.5 mm sealed gap that prevents rubidium vapor from exiting prior to encountering the holes. Within this gap, the rubidium vapor can rapidly thermalize with the plate, which is at a lower temperature than the dispenser due to the shielding of radiation from the dispenser that occurs. Moreover, the electrically isolating nature of the spacer prevents the collimator plate from receiving current and being inadvertently heated.

(a) Diagram of invention including integrated alkali metal dispenser, collimator plate and insulating spacer; (b) Photo of actual fabricated device with spacer partially removed to view both dispenser and collimator clearly along with the 0.5 mm gap between them; Microscope images of collimator plate front (c) and back (d) surface showing the 115 µm diameter, laser-etched holes in front and 40 by 75 µm ellipses in back; (e) Fluorescence image of rubidium atom beams emitted from individual holes (traveling upwards in the picture)