Georgia Tech inventors have created a Sodium Thermal Electrochemical Converter (Na-TECC), a two-stage electrochemical, solid-state system that has high efficiency and power density and is scalable to 1–5 kW. Using two cycles is thermodynamically favorable as it allows for regeneration from the isobaric cooling of the first expansion step and reheat to complete the expansion in the second step, increasing the efficiency of power generation. The Na-TECC directly converts heat into electricity by allowing high-pressure oxidized sodium vapor ions to expand isothermally through two ion-selective solid electrolytes. The free electrons produce power and then recombine with the cations. Once the sodium vapor condenses, a wick pumps the liquid into a high-pressure plenum to begin the cycle again. The converter’s configuration mitigates the thermal shock experienced across the relatively thin (~ 1 mm) membranes, reduces crack propagation in the solid-electrolytes, and limits the percolation of the molten dendrites. Its geometry improves thermal management by reducing thermal radiation losses. Novel electrodes reduce the overpotential and increase the power production, while a graded wick improves the pumping power.

- Lower cost: The working fluid and storage materials are inexpensive.

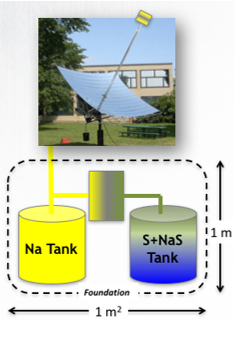

- Multifunctional: Multiple functions (e.g., solar conversion, thermal storage, electrochemical storage) can be integrated in a single system.

- High efficiency: This device’s heat-to-electricity conversion has the potential to be twice what has been achieved previously.

- Reliable, high specific power: The Na-TECC is capable of generating up to 0.2 kW/kg and includes an integrated storage feature.

- 20-year cycle life: The use of active scrubbing helps maintain the device’s performance through 7,000 cycles.

- Simple design: This closed system uses radiant and natural convection cooling without water or chemical reactions, produces no vibrations, and is relatively small and lightweight.

- Remote power generation (e.g., down bore, underwater, space power systems)

- Micro-combined heat and power systems

- Distributed concentrated solar power

- Portable generators

- Thermal-electric engines

- Biomass-based power generation

- Waste heat recovery/conversion

Given that world energy consumption is expected to rise 56% by 2040, more reliable distributed power systems are needed that efficiently convert heat into electricity. One option for boosting efficiency is to replace a single isothermal expansion step with a dual-stage conversion process. The dual-cycle approach uses two electrolytes to allow both high- and intermediate-temperature expansion steps. This design allows the engine to reach a lower condenser temperature, and therefore achieve greater efficiency, than is possible with a single-stage converter.