Innovators at Georgia Tech have developed novel methods for fabricating low-cost zeolite membranes used in molecular separation techniques. Both methods offer a path forward for utilizing zeolite sieves to accelerate scale-up and applications of thin, selective membranes for separating gases and other molecules for energy production, greenhouse gas mitigation, and other applications.

One method fabricates high-silica zeolite membranes directly on low-cost alumina hollow fiber substrates. This one-step process does not require a separate seeding operation or a liquid-phase hydrothermal growth. The use of concentrated precursor gels leads to the generation of highly permeable and selective membranes that exhibit efficient separations.

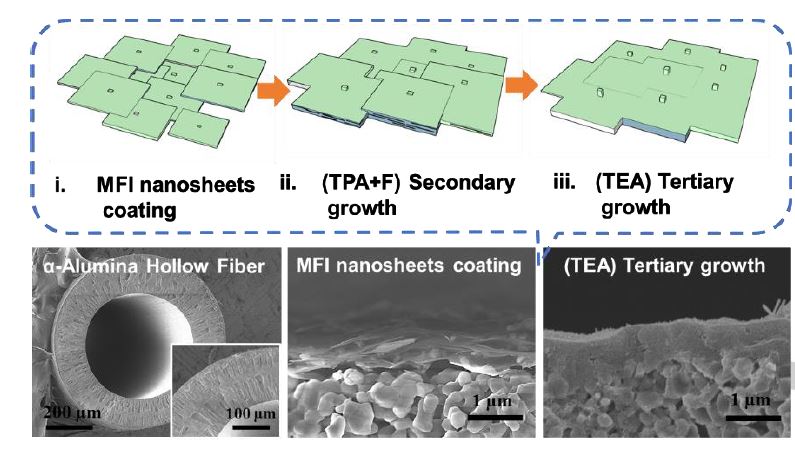

A second method also fabricates zeolite membranes on alumina hollow fiber substrates but begins with 2D zeolite nanosheets rather than precursor gel. The nanosheets are first coated on the hollow fiber substrates via vacuum filtration and then transformed into molecular sieving membranes.

Both methods allow scalable zeolite membrane fabrication on hollow fibers and also eliminate the need for expensive, specially engineered substrate materials.

The membranes resulting from these methods perform efficient molecular separations. Examples include the removal of carbon dioxide (CO2) from methane, nitrogen, and hydrocarbons in both dry and humid conditions; separation of butane isomers; and removal of higher hydrocarbons (natural gas liquids or NGLs) from methane.

- High performance: Enables lower-cost, scalable, membrane-based molecular separation

- Convenient: Can form a standalone complete separation or reduce bottlenecks in conventional separation processes

- Removing CO2 from natural gas (CO2/CH4 separation) and from power plant flue gas streams (CO2/N2 separation)

- Separating/splitting hydrocarbon mixtures in natural gas plants and petroleum refineries

- Producing purified hydrogen (H2) from gas and hydrocarbon mixtures

Zeolites are crystalline aluminosilicates with uniform pore sizes in the sub-nanometer range. They also possess excellent thermal and chemical stability. These features make them attractive molecular sieving membrane materials for energy-efficient separation for the emerging sustainable energy and chemical production sector. A key hurdle to their widespread adoption has been the high costs associated with expensive membrane substrates and complex membrane fabrication processes.

These Georgia Tech innovations offer effective fabrication techniques for low-cost zeolite membranes on inexpensive hollow fiber substrates, contributing to their accelerated development for molecular separation technologies.

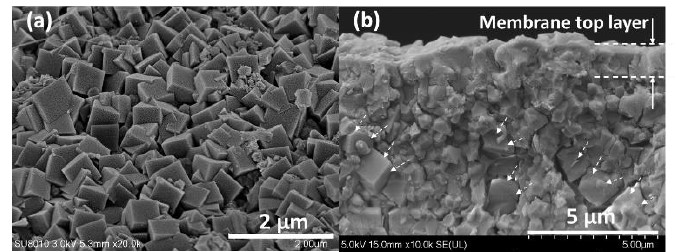

Example SEM images of (a) membrane surface and (b) cross-section

Zeolite MFI membranes are prepared on ceramic hollow fibers, starting from 2D zeolite MFI nanosheet coatings and followed by secondary and tertiary hydrothermal treatments. These membranes show separation of butane isomers and of natural gas liquid components from methane.