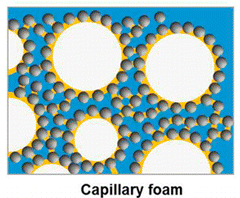

Inventors at Georgia Tech have identified a method that utilizes surfactant-free, oil-tolerant capillary foams consisting of a combination of colloidal particles, oil, water and gas. This method allows the recovery of off-shore oil spills that allows the subsequent recovery of the oil. A collection device allows the infusion of air and the addition of colloidal particles. As the oil and water is processed through the device, a capillary foam gel is formed. The foam cells are stabilized synergistically by oil and (readily available, inexpensive) solid particles of appropriate wettability, without the need for any surfactants. Networks of oil-bridged solid particles inside the aqueous lamella of capillary foams confer upon the foam a tunable viscosity. The accumulated foam can be mechanically removed from the water surface (either by skimming, scooping, or pumping), and transported to another location where a de-foaming agent can be added to “decompose” the capillary foam into its component parts (water, recovered oil, and stabilizing particles). In addition to facilitating the removal of spilled oil, the proposed technology also promotes the biodegradation of unremoved oil by spreading it in a thin film around air bubbles and by transporting it into the upper water regions most populated by oil degrading organisms. The capillary foam is easily formed by introducing air and environmentally-friendly colloidal particles, composed for instance of silica, and the foam formation can easily be reversed to recover the oil.Aqueous capillary foams show outstanding stability in contact with crude oil. In fact, capillary foams can be formed by using crude oil with appropriately-chosen particles.

- Improved performance- better solution over existing enhanced oil recovery mobility-control methods

- Effective- efficient capture of the spilled oil

- Low-cost- affordable materials

- Environmentally friendly

- Mitigating oil spills

Current methods for mitigating off-shore oil spills involve the dispersion of oil into fine droplets in order to promote biodegradation. These methods are slow and do not allow recovery of the valuable oil. Forming a capillary foam gel to encase the spilled oil allows effective remediation of the oil spill and allows de-foaming agents to be later used to recover the oil.