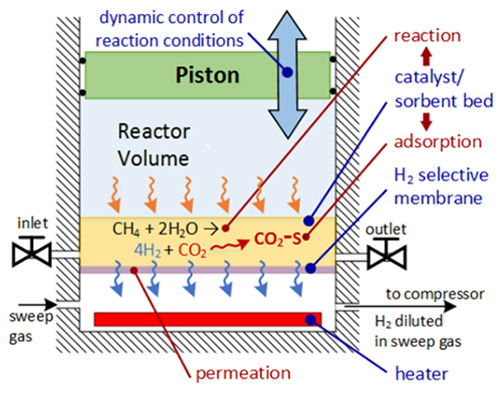

Georgia Tech inventors have developed a method and apparatus for generating hydrogen from hydrocarbon fuels at high power density and adaptive throughput with a very low (CO) concentration (<10 ppm), thus eliminating the need for separate CO-cleanup units. The technology combines the processes of fuel reforming, water gas shift, compression, and hydrogen separation into a single, scalable unit. It is ideal for use with proton exchange membrane (PEM) fuel cells and power plants operating between 1 W and 100 kW. A unique aspect of the innovation is its piston and cylinder assembly that operates in a four-stroke cycle to generate hydrogen at a highly selective and scalable manner. The reactors offer precisely controlled volume, pressure, temperature, and reaction time. Precision actuators move reactants and products in and out of the chamber at the appropriate times. The walls of the reactor and/or actuator may be selectively permeable to one or more of the reaction products, resulting in product purification as well as shifting of reaction equilibrium in a favorable direction. Each reactor unit is optimized for performing a specific reaction or multiple reactions and/or separation steps. Scale-up to required power is achieved by parallel operation of multiple identical units.

- Controlled operation: achieves maximum conversion of fuel to hydrogen and CO2

- Optimal sizing: performs at most favorable operating conditions to optimize output

- Rapid scale-up: allows reactors to be stacked for increased processing capacity

- Seamless integration: combines multiple reactions in a single operating unit

- Portable power generation

- Automotive applications

- Distributed power generation and chemical production

- Point-of-use energy generation

Hydrogen is the energy source of choice for fuel cells, for power generation, and have many other industrial uses. Methanol reformers can produce hydrogen and carbon dioxide (CO2) via a chemical reaction between methanol and water in the form of steam; however, the conventional large-scale, continuous-flow reactors are not readily adaptable to portable or smaller scale distributed power applications due to poor down-scalability and inability to accommodate dynamically variable throughput demand. In addition, the current technology does not allow to produce a concentrated CO2 stream, which is essential for carbon capture and sequestration.

See other hydrogen fuel–related technologies by Dr. Fedorov. To see his entire portfolio of available technologies, click here.

Schematic shows the components of a CHAMP cylinder-piston assembly used to create hydrogen from methane and steam via variable volume catalytic reaction. The process also concentrates carbon dioxide emissions from the process. (Credit: David Anderson, Georgia Tech)

Georgia Tech researchers have demonstrated a CHAMP reactor, which uses the four-stroke engine cycle to create hydrogen while simultaneously capturing carbon dioxide emission. (Credit: Candler Hobbs, Georgia Tech)