Each year, government and industry make significant investments in maintenance systems that often fall short because they are reactive and disjointed rather than proactive and holistic. Replacing outdated reactionary maintenance and sustainability procedures is a complex challenge because they span several services, platforms, and operations. For large-scale systems, such as aircraft maintenance, the lack of predictive maintenance (PMx) can translate into significant loss of time, money, labor hours, and asset availability.

A Proactive, End-to-End Predictive Maintenance Solution

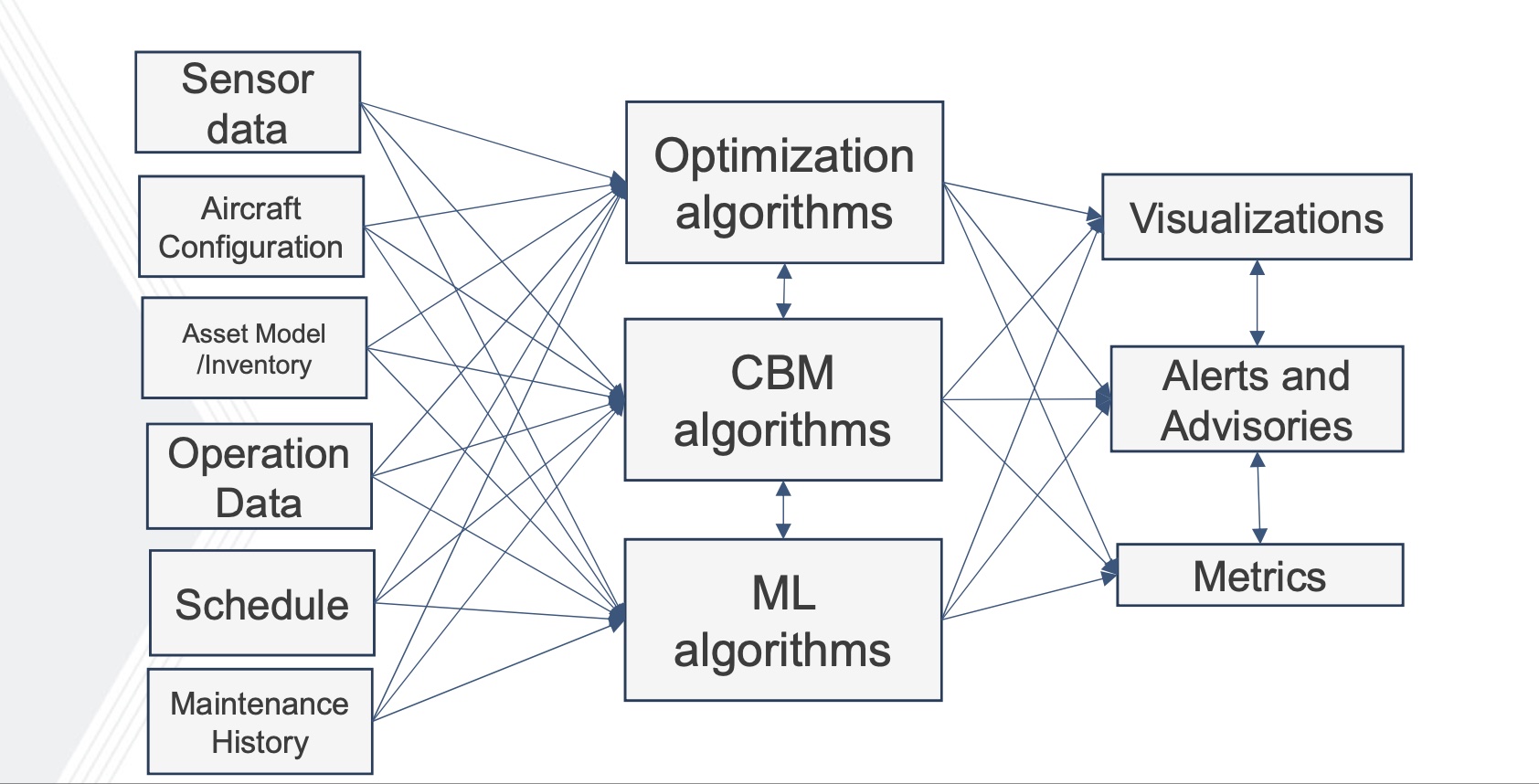

The Strategic, Predictive and Enhanced Analytics for Readiness (SPEAR) offers a proactive solution in the form of a data pipeline architecture for a robust PMx system. SPEAR innovates across the entire pipeline, acquiring critical data, using model-based systems engineering to identify new information, employing a logical decision-making tree to improve upon current processes, and then delivering the resulting information to the end user while reducing their workload. What sets SPEAR apart from existing solutions is that it takes a holistic approach, places a focus on end users, and maintains a modular framework that makes it highly adaptable and applicable across several industries. The proactive nature of the SPEAR pipeline turns unscheduled maintenance into scheduled activities, significantly reducing the negative impact to the organization.

With a core framework of reliable artificial intelligence and machine-learning algorithms, SPEAR provides a proactive PMx system with significant benefits:

- Consistent workflow improvements: Offers repeatable and consistent enterprise-level improvements to the maintenance workflow.

- Proactive readiness: Improves maintenance scheduling, allowing for improved logistics, scheduling, virtual kitting, and part/component availability.

- Customizable: Customers can build and tailor their PMx solutions according to their needs, providing increased data control and an alternative to costly and limited solutions.

- End-to-end solution: Innovates across the pipeline to improve capabilities each step of the way from data capture to end-user interfacing.

- Workload reductions: Acquires, processes, and delivers information to the appropriate personnel efficiently.

- Potentially significant cost savings: Billions of dollars in cost improvements have been estimated for a government application. For the private sector, cost savings are also expected to be significant.

- Workforce and asset availability: Just as important as cost savings, gains of increased resource availability such as labor or decreased asset downtime are significant.

- Aircraft and spacecraft maintenance for on-time vehicle readiness

- Predictive wear and maintenance on parts (e.g., aviation tires)

- Integrated PMx that transforms unplanned part/labor/equipment needs into scheduled maintenance

- Modular use across industries for large-scale operations such as warehouses, automotive fleets, freight hauling, or bus operations

The Strategic, Predictive and Enhanced Analytics for Readiness (SPEAR) maintenance system.