Inventors at Georgia Tech have developed a new cleaning method for removing pollutants from the exterior surfaces of contact lenses. Referred to as polymer-on-polymer pollutant removal (PoPPR), the technique takes advantage of the elastic properties of synthetic, biocompatible polymeric materials (e.g., polydimethylsiloxane), enabling physical removal of contaminants from lenses (and potentially other biomedical device surfaces). Removal has been demonstrated for pollen, microplastics, and nanoparticles (aerosols).

Compared to conventional cleaning methods, Georgia Tech’s technology has been proven as effective for large particles such as pollen and significantly more effective for removing fine particles, nanoparticles, and microplastics. The robust and efficient cleaning protocol may enhance the safety, health, and comfort of contact lens wearers, especially those living in regions with significant pollution.

- Effective: Removes large-particle pollutants as effectively as traditional cleaning solutions, and removes smaller pollutants and microplastics with significantly higher efficacy

- Robust: Utilizes an elastic polymer that enables contact force between two elastic materials to do the work of removing particles of any size

- Safe: Eliminates the need for soaking and rubbing removal methods that may tear or damage contact lenses

- User friendly: Eliminates the need for surfactants, aqueous solution, and washing steps and does not require the user to learn any unique rinsing protocol

Any biological device with a soft, wet surface that may be at risk of accumulating pollutants may benefit from this technology, including:

- Contact lenses

- Prosthetics

- Implants

Worn by more than 150 million people, contact lenses are exposed to many artificial and biological/environmental air pollutants. Traditional methods of cleaning include rinse-and-rub methods and soaking, which may damage or tear lenses and provides limited efficacy for fine particles and nanoparticles, such as aerosols. By contrast, Georgia Tech’s method employs the contact force between two elastic particles to remove pollutants. In addition, the user-friendly method eliminates the need for surfactants, aqueous solutions, and washing steps.

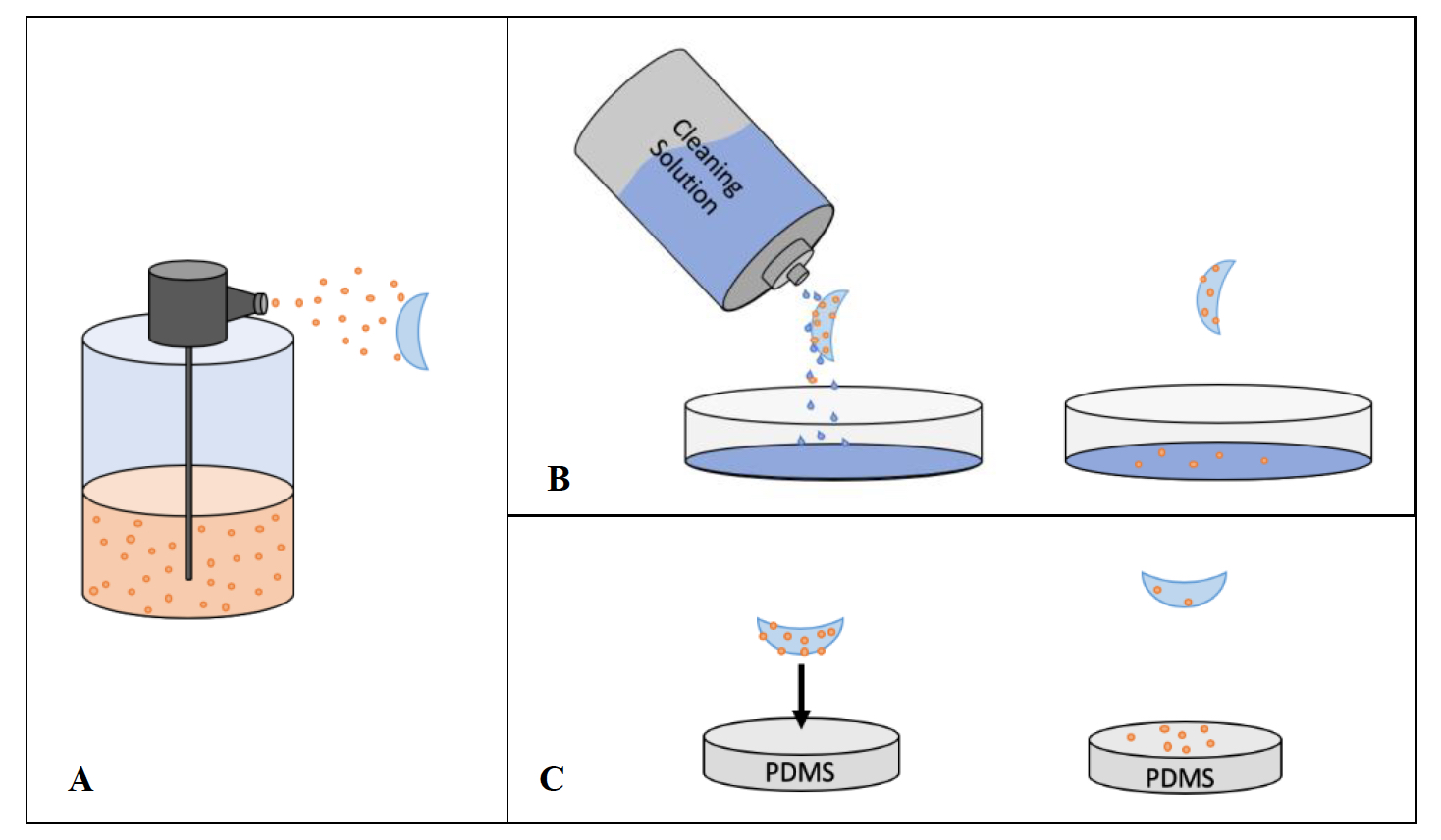

A comparison of traditional (B) and PoPPR (C) methods of cleaning contact lenses. A: For both methods, pollutants suspended in water are sprayed onto a contact lens. B: After rubbing the contact lens between the thumb and forefinger, it is rinsed with cleaning solution. Pollutants on the contact lens and in the cleaning solution are then counted. C: A polluted lens is pressed onto a sample of polydimethylsiloxane (PDMS) with normal force, then lifted off of the surface. The pollutants on the contact lens and on the PDMS are counted. This comparison shows significantly less pollutant remaining on the contact lens cleaned with the PoPPR method.

Georgia Tech’s PoPPR method for contact lenses is shown here.