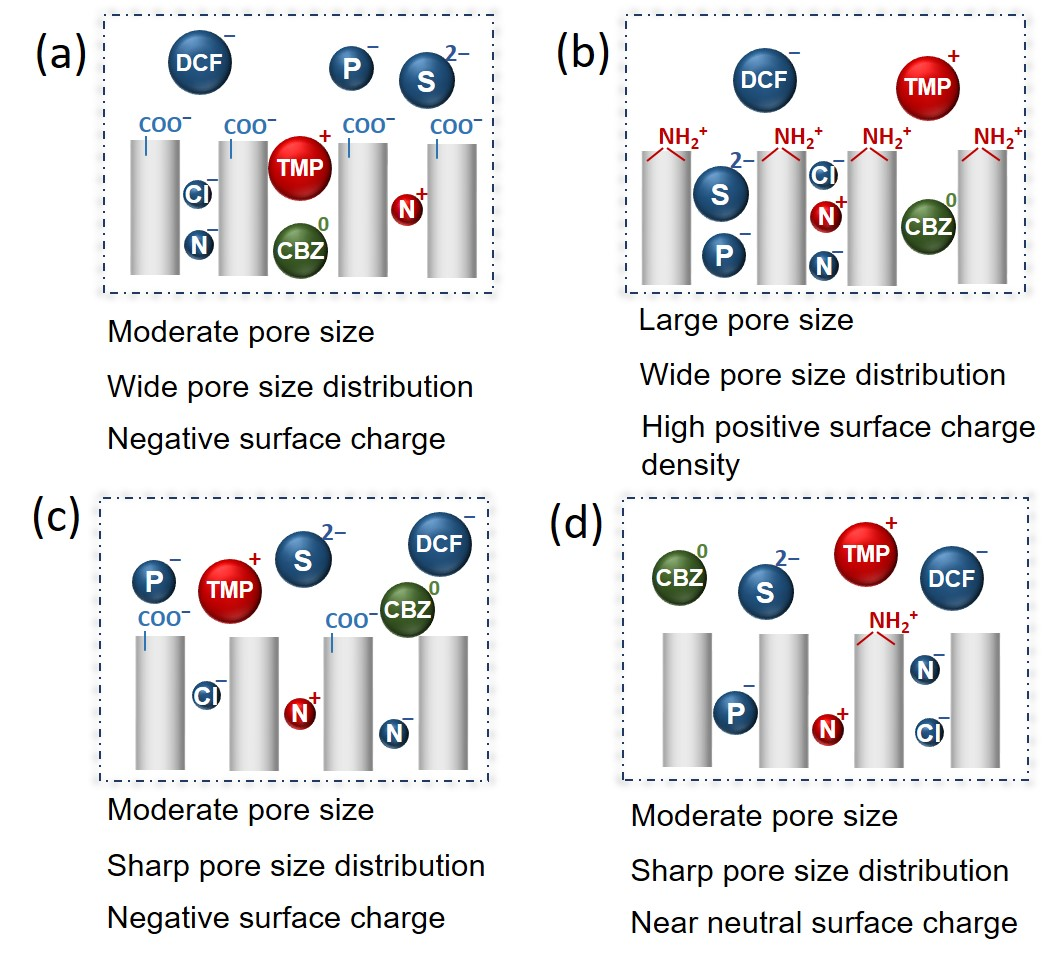

This thin-film composite polyamide (TFC-PA) NF membrane has been optimized for improved permeation of valuable nutrients from domestic wastewater while excising harmful emerging micropollutants (EMPs). Georgia Tech’s novel method used to develop and treat the TFC-PA NF membrane allows for a more precise pore size and narrower pore size distribution of the membrane compared to the current market offerings. The superior pore size characteristics allow an increased quantity of EMPs to be rejected while permitting smaller nutrient ions to pass through, thus obtaining a greater solute-solute separation. Minimizing the EMPs diminishes the likelihood of agriculture absorbing the detrimental compounds, reducing contaminated produce being ingested by the public.

Additionally, this novel membrane has been curated to decrease the density of its negative surface charge beyond market standards. With a nearly neutral surface charge, the TFC-PA NF membrane allows for valuable nutrients such as nitrogen and phosphorus to permeate the membrane and be of considerable benefit to agriculture when the fit-for-purpose water is used in irrigation.

The tailored TFC-PA NF membrane’s development and treatment are within the parameters of existing commercial manufacturing processes, enhancing this technology’s market readiness.

- Effective: Targets mainstream domestic wastewater to recover a greater volume (>30%) of valuable nutrients than the current industry nutrient recovery technology focused on side streams

- Safer: Reduces EMPs in the fit-for-purpose water used in agricultural irrigation, minimizing the contaminants charge while permitting a lower rejection rate of valuable nutrients

- Domestic wastewater treatment

- Environmental agriculture

Nanofiltration membranes control solute-solute selectivity through nanosized pores, surface charge and other factors. Wastewater treatments currently utilize NF membranes, though there is significant room for optimization to bring greater efficacy to environmental sustainability. Standard industrial nanofiltration membranes produce a rejection of 30% to 50% of the valuable nutrient phosphorus. Known efforts to lower the rejection rate result in a significant cost increase to modify the correlated increase in pH. Georgia Tech’s innovation answers the need for a cost-effective, environmentally sustainable NF membrane that is designed to increase the recovery of valuable nutrients while eliminating EMPs.

Schematics illustrating the various membrane characteristics that can be fabricated using Georgia Tech’s innovative process.