This technology is a platform for the development of composite precursor hollow fiber membranes that could optimize large-scale gas separation applications. Carbon molecular sieve (CMS) membranes are known for their permeance and selectivity, and this asymmetric Georgia Tech design of their precursor polymers is intended to make the membranes more dependable and effective.

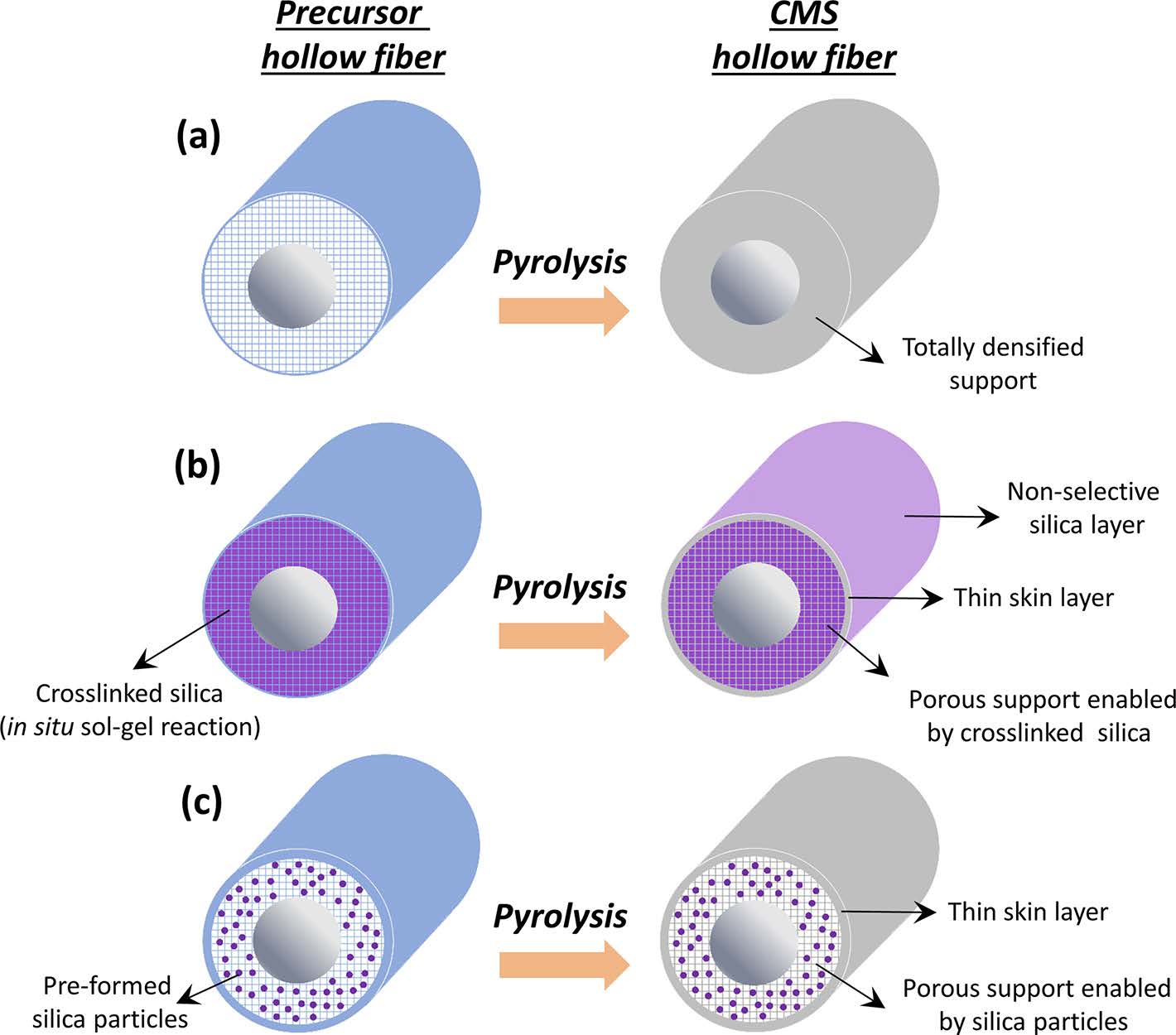

Specifically, this technology is designed to reduce CMS fiber collapse during pyrolysis while allowing for economical integration into CMS precursor formation. Substructure collapse can result in increased thickness of the separation layer—which often causes a drastic loss in gas permeance—and its prevention is important for the enabling of practical CMS applications. Tests show that a multilayer CMS precursor hollow fiber with an inner nanoparticle core support layer and an outer sheath layer can eliminate the need for post-treating precursor fibers. Elimination of this additional conventional method for preventing collapse can reduce cost and complexity to the fabrication process.

- Cost efficient: Eliminates the need for the time-consuming process of post-treating precursor fibers in a chemical modifying agent in order to prevent collapse

- Scalable: Increases available surface area for gas separation to accommodate large-scale applications

- Adaptable: Allows for selection of the nanoparticles’ concentration and type to meet a desired combination of gas permeance and selectivity

This technology could enable advances in gas separation across the energy sector, as molecularly selective membranes can reduce the carbon dioxide (CO2) footprints of large-scale chemical separations. Other applications include but are not limited to:

- Air separation

- Natural gas processing

- Hydrogen purification

Carbon molecular sieve membranes are advantageous for gas separation applications because of their precise capability to discriminate between the sizes and shapes of different molecules. Additionally, their rigid structure prevents plasticization under high pressure. A hollow fiber configuration increases the surface area available for large scale gas separation operations, but controlling the macroscopic fiber morphology to restrict substructure collapse is critical for the membranes’ widespread use. This Georgia Tech research team has developed an innovative approach for restricting CMS structure collapse without reducing the bulk flow mobility of the membranes’ polymer chains.

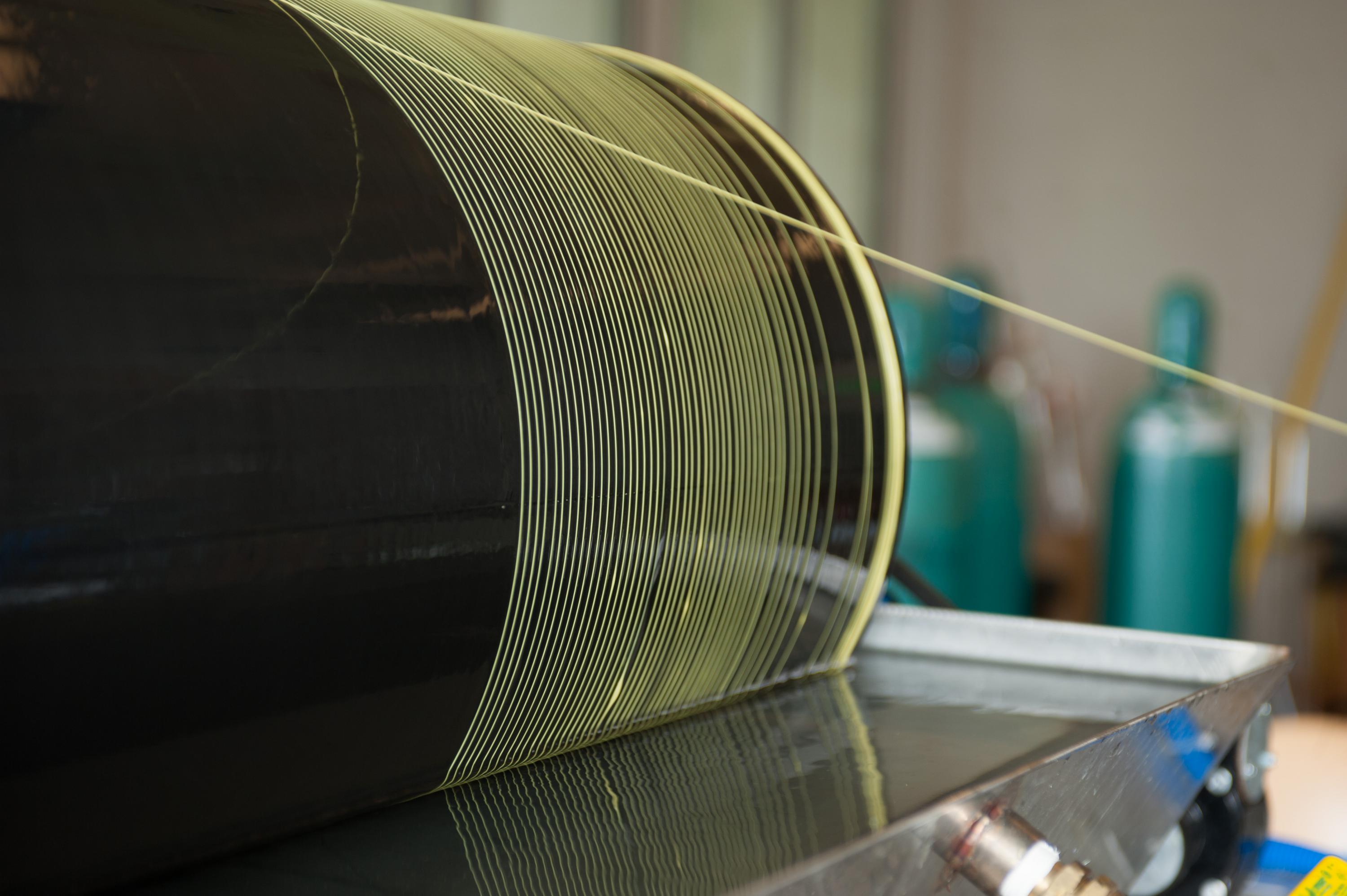

The manufacturing of polymer hollow fiber membranes

The formation process of CMS hollow fiber membranes (light blue represents polymer precursor; light gray represents carbon molecular sieve; light purple represents in situ formed cross-linked silica or preformed silica particles)