Researchers at Georgia Tech have developed a new approach to fabrication similar to drawing lithography but with several features that greatly enhance its usefulness. Whereas drawing lithography has been limited to photoresists and used mainly for the fabrication of biomedical microneedles, Georgia Tech’s unique and versatile method expands its applicability to new areas.

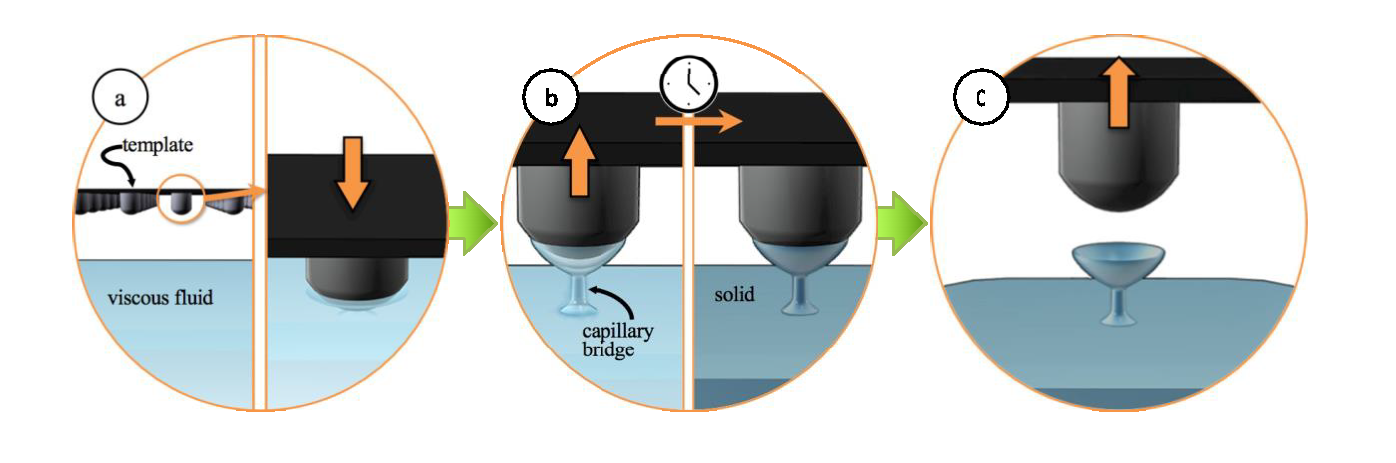

This novel process for fabricating patterns with a defined tip geometry uses polymers in any of their fluid states (molten, dissolved or thermosetting resins) instead of being limited to thermosetting resins, the most common photoresist material in photolithography. Patterns are shaped by lowering a template into a viscous precursor so that the liquid forms a meniscus. When the template is lifted, a capillary bridge connects the precursor and the template. This bridge is subsequently transformed into a solid through proprietary methods. This process holds many advantages over common high aspect ratio fabrication methods like photolithography, including its simple setup.

- Innovative: Pioneers a new method, expanding the applications of drawing lithography for shapes other than sharp point geometry

- Straightforward: Introduces a simpler procedure that, unlike photolithography, does not require a cleanroom or ultraviolet (UV) curing, making it viable for continuous manufacturing

- Flexible: Includes parameters that can be tuned to produce patterns of different sizes and shapes

- Diffractive surfaces

- Glare-reducing windows

- Solar panels

- Photonics

- Optical microresonator arrays

- Reversible adhesion surfaces

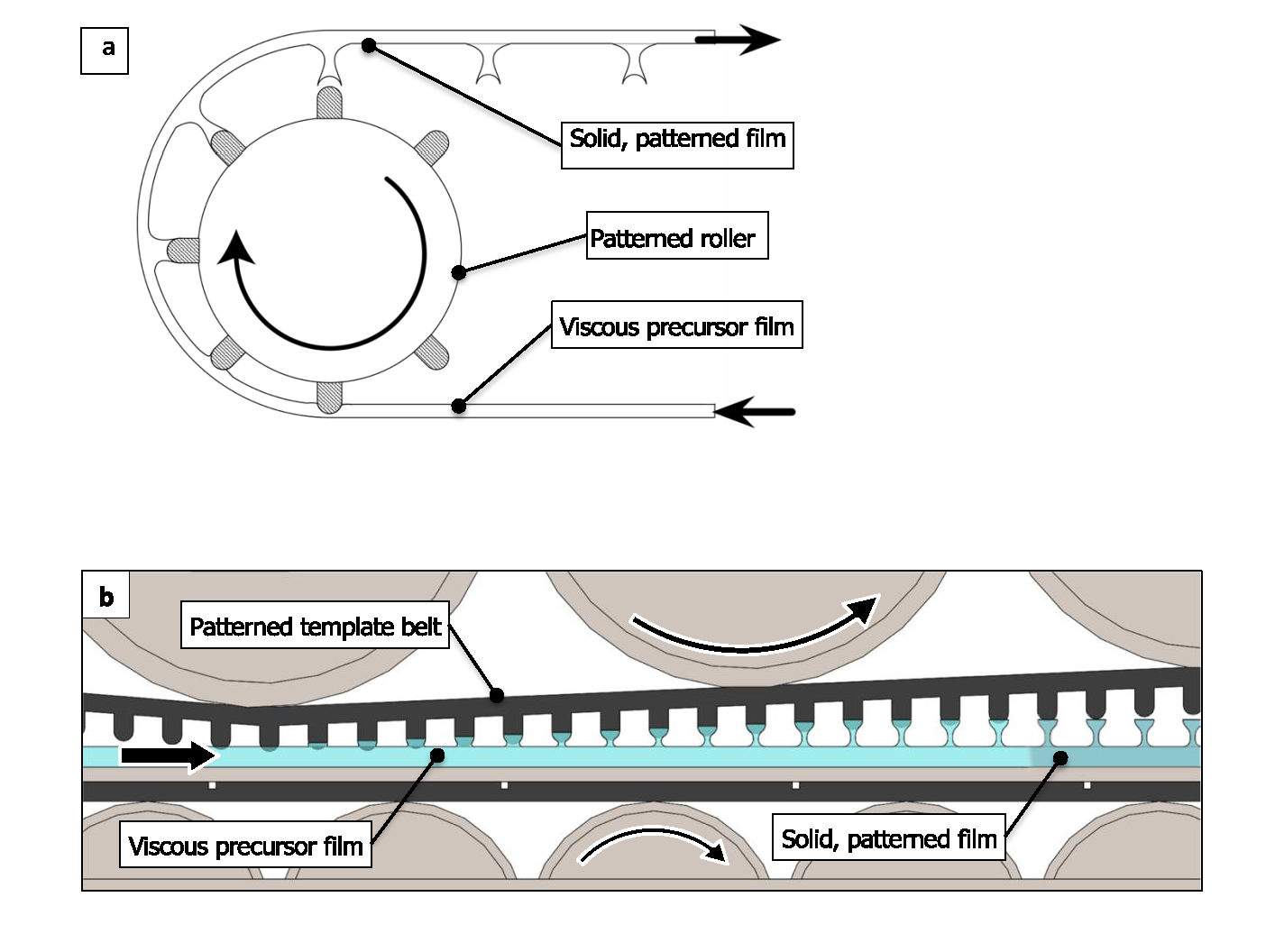

Surface structures are usually prepared via thermosetting resins and photolithography, a process that uses light through a pre-patterned mask to prepare a mold. This method, however, requires special equipment and would be challenging to scale. Drawcasting is an extensional deformation process that uses viscous material to draw templated patterns. It involves only basic, widely available equipment and can be used with a variety of materials. The novel use of drawcasting in Georgia Tech’s new fabrication method has the potential for high-level industry production.

An overview of Georgia Tech’s drawcasting process with a patterned template

An example of continuous drawcasting manufacturing