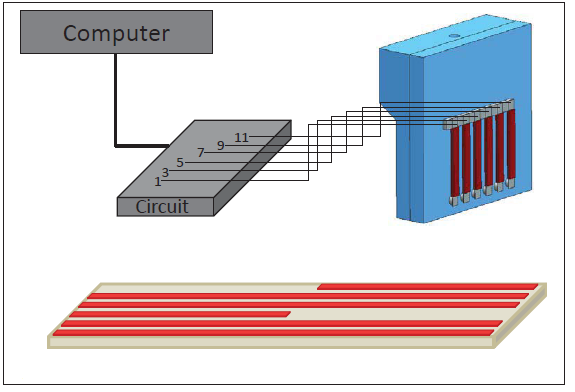

Georgia Tech inventors have developed an innovative hybrid tooling system that enables an additive approach for continuously creating discrete or non-discrete patterned films. Based on a novel method of controlling flow, the technology systematically integrates computer-aided design (CAD), a complex algorithm, and the tool. First, the system receives an initial pattern from CAD and converts it into an automation command. Then, it digitizes and sends the command to the actuation system, which executes the command to create the pattern.

The tooling itself is comprised of a slot die offset by a shim. The bottom surface of each die half is equipped with an array of pins that are actuated based on the automation commands.

The advantage of this hybrid tool is that it allows for a purely additive approach to making layer-based devices without the need for an additional subtractive step. With the integration of CAD into the system, the process allows for making complex patterns that cannot be realized by other technologies. This single-step process will also allow for significant cost savings over traditional methods, especially when processed at ambient conditions.

- The technology provides dynamic, in-process patterning that will benefit the mass production of layer-based thin film devices

- This new approach allows for a purely additive approach to making layer-based devices and does not require an additional subtractive step

- The integration of CAD into the system allows for making complex patterns

- The single-step process and compatibility with ambient condition processing allow for significant cost savings over multi-step processes

This technology can be used to make single- or multi-layer thin film devices in various industries, including energy, environmental, and electronics. Applications may include organic solar cells, organic LEDs, batteries, thin film transistors, radio frequency identification tags, and other devices whose manufacturing methods are currently restricted to ink jet printing and vapor deposition.

Existing high-throughput coating technologies are able to manufacture thin films in continuous single sheets but generally require a secondary etching or ablation process to pattern the coating. Emergent technologies, such as organic electronics, are compatible with these processes and can also be processed in ambient conditions, making them low cost and conducive to mass production. However, the market is currently limited to rigid slot die designs that only allow for the extrusion of lines or stripes that are the width of the shim opening. Thus, there exists a need for a high-throughput technology that can process materials with different patterns such as circles, lines, and wafers.