Georgia Tech researchers have developed an innovative process to enable use of regenerated silk fibroin solutions with an aerosol jet printer. This method reliably processes silk fibroin material without the need for chemical additives that may negatively alter the mechanical properties of RSF. Additionally, it demonstrates a reduced likelihood for clogging the printer’s nozzle—a typical challenge of other processes, like inkjet printing.

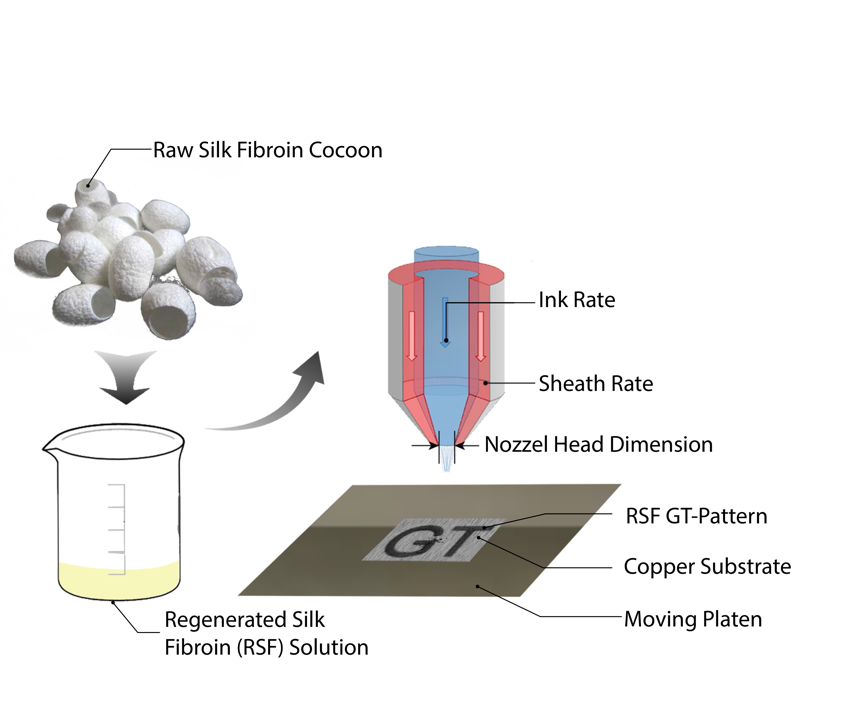

This procedure involves two phases of working with the RSF to print patterns: material preparation and material fabrication. The silk fibroin is first processed from its raw form into a printable liquid solution through a unique progression of degumming, dissolution, dialysis, and centrifugation. The solution is then atomized, and the final parameters are tuned before the printed pattern is finally deposited. In this method, the printer’s focus ratio—composed of its sheath and ink rate—is customized to establish an operating window for optimum print quality.

- High fidelity: Preserves silk fibroin’s advantageous mechanical properties by creating a printable RSF solution without the need for chemical additives

- High quality: Identifies the optimum parameters for producing printed patterns with minimal flaws

- Efficient: Reduces obstacles (e.g., clogged nozzle and overspray) normally encountered in other processes, like inkjet printing

- Broadly applicable: Expands potential use of silk fibroin material in an array of commercial contexts, including but not limited to medicine, food production, and biosensors

- Medicine

- Wound treatment

- Surgery

- Medical devices

- Drug delivery and pharmaceuticals

- Food and beverage

- Packaging

- Sensors

- Electronics

- Photonics

- Filtration membranes

Silk has been hailed as a multi-purpose material for centuries, thanks to its versatile mechanical properties, biocompatibility, and biodegradability. Its use in industries like medicine and food production, however, requires an efficient, non-contact printing method that can produce highly precise patterns. Aerosol jet printing has been identified as a promising technique for developing objects from RSF, as it can process drop volumes much smaller than inkjet printing and with a wider range of viscosity. To address the issues of RSF’s low printability in aerosol jet printers, this technology prepares and fabricates RSF material in such a way that—when combined with particular parameters—it can print high-quality samples with more ease and adaptability.

This innovation is a unique method and process for reliably printing regenerated silk fibroin material.

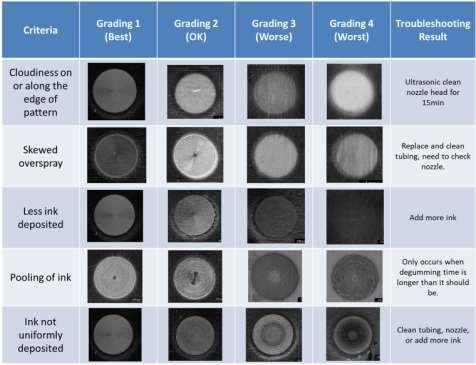

This diagram shows ways to adjust various printer parameters in order to improve print quality in each of the typical troubleshooting areas.