This new approach for flexible power generation produces energy with negative CO2 emissions and can dramatically reduce the cost of a net-zero carbon system. The modular system combines a natural gas combined cycle (NGCC) power plant, a conventional post-combustion carbon capture (PCC) system, and a direct air capture (DAC) system.

Georgia Tech’s technology achieves positive power with a negative carbon footprint across a wide range of operation of an NGCC plant from 100% to 25% of full load. The modular nature of the DAC system allows for partial operation, making it highly flexible and allowing power generators to respond to variable renewable energy (VRE) production. Emissions are reduced by up to 97% with the conventional PCC and then further reduced to negative with DAC. The system takes advantage of variable electricity pricing by changing the amount of DAC —increasing the amount of DAC when the electricity price is low and decreasing when it is high.

- Energy security: This system enables the continued use of low-cost domestic fuel (i.e., natural gas) for electricity generation and increases the reliability of U.S. electricity production.

- Environmental protection: Flexible carbon capture and storage (CCS) systems can achieve high CO2 capture rates from flue gas. For example, with this system a power generator could shift the times it exports electricity to the grid, allowing the power generator and CCS plant to operate under steady-state conditions and with reduced emissions.

- Reduced costs: The cost of a net-zero carbon electricity system is lowered by providing dispatchable power to a high-VRE grid.

- Scalable: The technology can be scaled up for direct atmospheric capture of CO2.

- Efficient: The DAC unit has the ability to treat gas streams with relatively low concentration of CO2.

This technology is particularly applicable to CCS-equipped power plants in high VRE environments.

Power plants equipped with CCS technologies can reduce the cost of net-zero carbon systems, but the addition of VRE sources like wind and solar can make them difficult to design and operate. Increased cyclic operation of electricity generators could also reduce capacity and efficiency, increase operations and maintenance costs, and potentially increase CO2 emissions. Georgia Tech’s system is designed to improve CCS processes and enable dispatchable, low-cost, net-zero carbon power generation.

How It Works

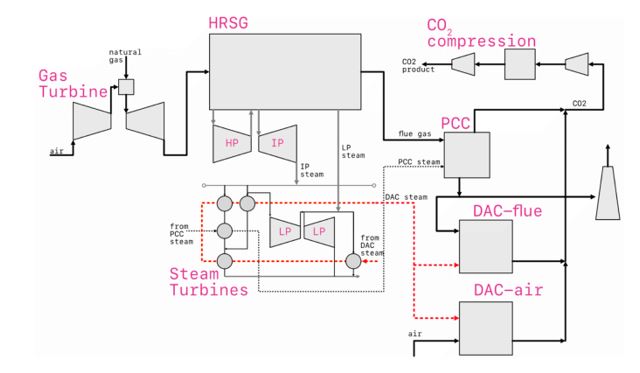

This system integrates an NGCC plant with a conventional amine capture system and DAC. The integration involves taking steam from the heat generation and recovery system of the natural gas plant for use in the reboiler of the amine capture plant, as well as extracting low-temperature heat to use for DAC. The amount of low-temperature heat can be varied to increase the amount of DAC during times when the electricity price is low and decreased when it is high. The state of the DAC system is optimized to take advantage of the variable price. The NGCC plant runs continuously with the conventional PCC system removing CO2 at its most efficient level. In times of low demand, steam and power from the natural gas plant remove CO2 from the atmosphere.

Simplified block diagram of the flexible power generation plant