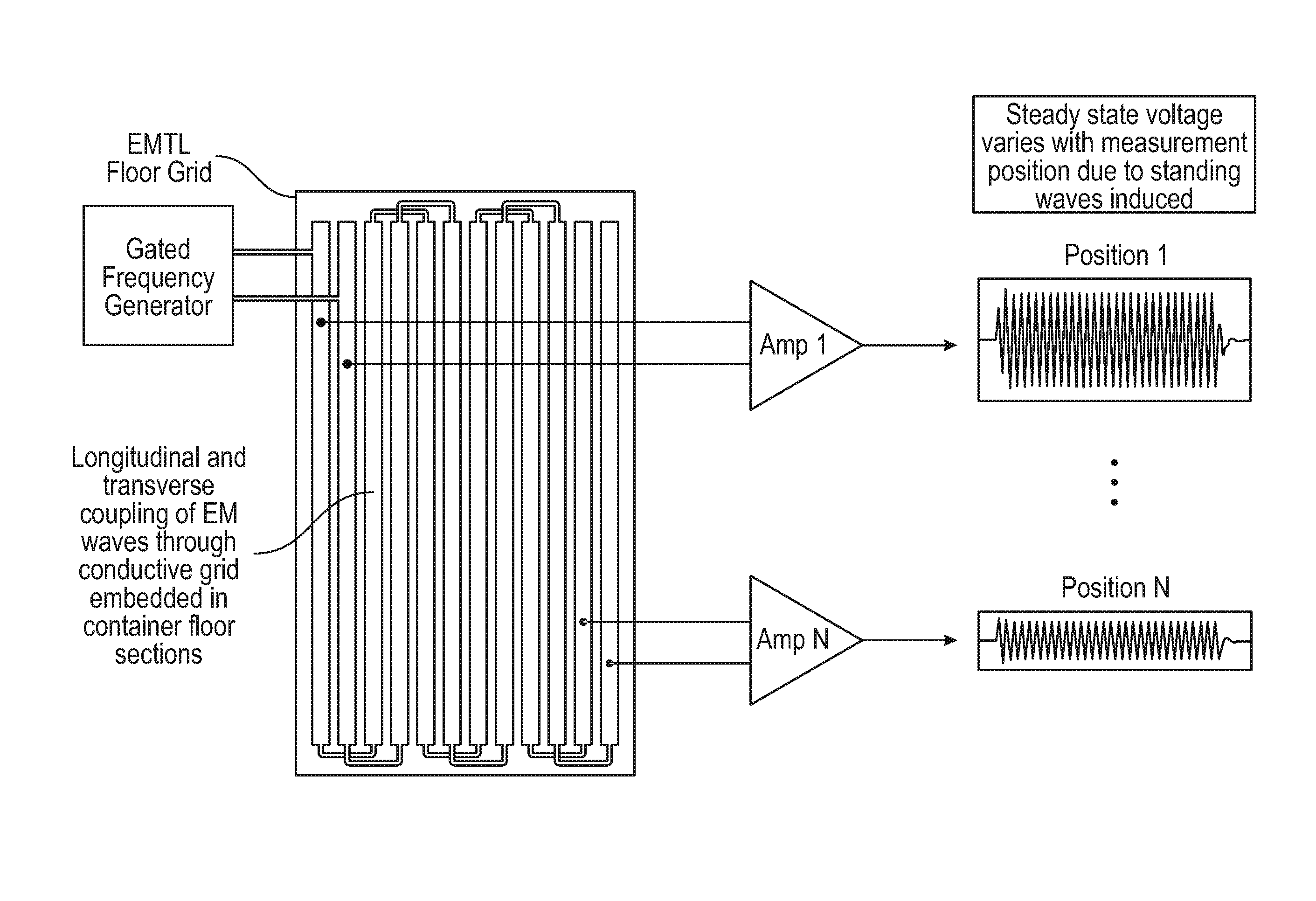

Georgia Tech inventors have created an electromagnetic transmission line (EMTL) method for detection of breaches in the floor section of shipping containers.The EMTL sensor consists of a grid of parallel conductive strips that are installed on the floor between two plywood sections in order to form an electromagnetic transmission line. The spacing of the conductors and the construction of the grid is such that driving nails through the floor and other damage will not significantly alter the conductors in the grid. However, cutting a hold with an area greater than nine inches will break the grid and thus change the characteristics of the transmission line. The concept has been successfully demonstrated on a plywood mockup of a container floor section, where holes were drilled and sawed to simulate breaching methods. The EMTL method was effective for detecting those breaches.

- Difficult to defeat — due to unique voltage patterns

- Works independently — not reliant on perfect connections to maintain functionality

- Ability to sustain a moderate amount of damage — to avoid incorrectly detecting a breach

- Security industry

- Advanced security system for cargo shipping containers

- Detecting penetration of secure enclosures

Simple conductive grids are often used as barrier breach detection sensors; however, conductive grids are easily defeated and ineffective, and must be repaired if a break in the grid occurs. A breach is defined as any intrusion attempt producing a hole nine inches or larger, and must be detected within two minutes of occurrence. Due to unique threats posed to cargo shipping, the sensor must be insensitive to nails driven through the floor, floor damage associated with normal use, cargo loading conditions, as well as insensitive to humidity and moisture content. There is a need for a sensor that is resistant to these challenges and capable of accurately detecting a breach.