This drive belt features a surface pattern that minimizes both local and global belt vibrations and self-oscillations in belt driven systems. Georgia Tech’s innovation addresses the uncontrollable and unstable contact interaction between belt systems and pulleys caused by detachment waves. These waves form in the interaction between a belt and pulley or other surface due to uneven contact forces. This often results in vibration, noise, diminished accuracy, energy loss, and increased wear. All of these deleterious effects can degrade performance and shorten the service life of machine components. Georgia Tech’s innovative surface texture reduces propagation of detachment waves by locally decoupling contact regions from each other. If one part of a contact surface is disturbed by detachment, the belt does not pass on that disturbance to adjacent parts of the contact surface. As a result, formation of a detachment wave is inhibited.

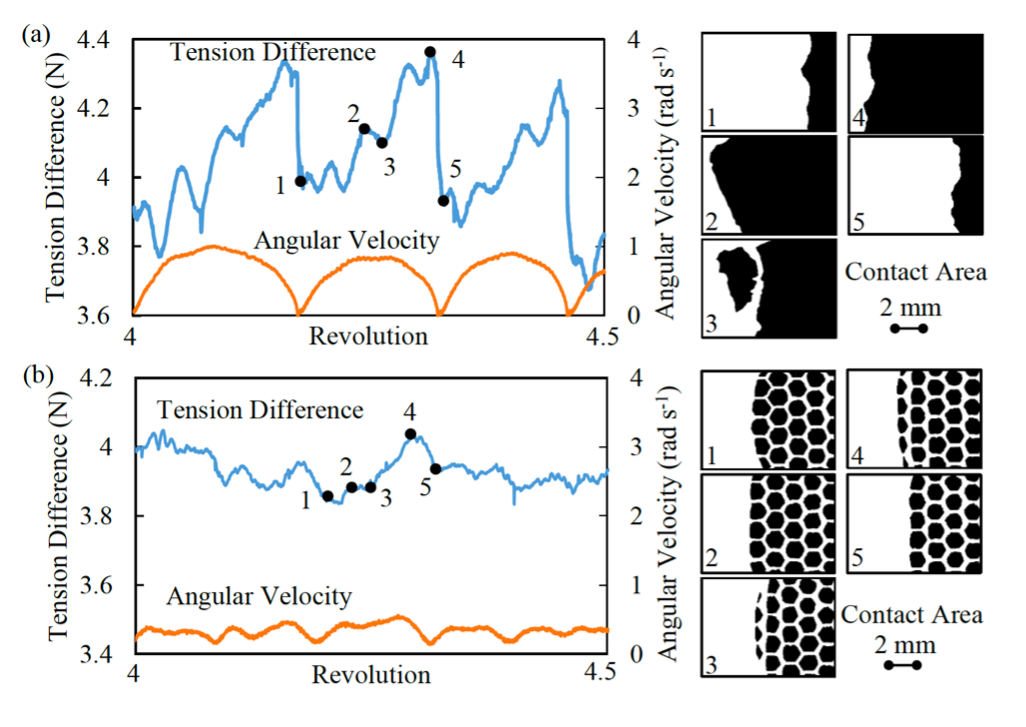

Georgia Tech researchers have demonstrated the innovation’s efficacy in preliminary testing. Both regular and irregular surface patterns showed significant improvement over flat, untextured belts in reducing detachment wave-induced instabilities and thereby minimizing vibrations with regular surface patterns providing the strongest effect. The height-to-diameter aspect ratio of the surface elements featured in the innovation is specifically designed to maximize the pattern’s efficacy in inhibiting detachment wave formation.

- Effective: Demonstrated significant reduction in vibration compared with flat, untextured belt surfaces in preliminary testing

- Simple: Provides a straightforward and easy-to-implement solution to a widespread problem

- Economical: Offers a far less expensive means of maintaining the operation of machinery compared with replacing worn belts or employing complex tension systems

- Power transmission in many mechanical applications, including:

- Kitchen appliances

- Industrial conveyors

- Elevators and moving sidewalks

- Printing presses

- Pumps

- Engines

- Compressors

- Mixers

- Exercise equipment (e.g., treadmills)

- Medical equipment (e.g., peristaltic pumps and centrifuges)

- Designing novel passive-vibration-suppressing belts for mechanical systems

Belt drives are used in the transport of people and materials as well as power transmission at nearly every scale. Yet despite their longstanding use, even modern belt systems suffer from unstable contact interaction with pulleys, resulting in inefficiencies and often unreliable operation. Georgia Tech’s innovation directly addresses the core causes of these instabilities with a simple and straightforward approach for texturing belt surfaces.

Left: Tension difference and angular velocity measured on (a) reference flat belt and (b) hexagonally patterned belt. Right: Characteristic sequences of images representing evolution of the contact area.