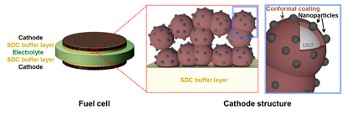

This technology was developed to provide faster oxygen-reduction reactions (ORR) in solid oxide fuel cells (SOFCs) while maintaining durability. It dramatically enhances ORR kinetics and stability of current lanthanum strontium cobalt ferrite (LSCF) cathodes by applying an efficient electro-catalyst coating derived from a low-cost, one-step infiltration process. The coating is a conformal perovskite nickel manganese (PNM) film and highly active praseodymium oxide nanoparticles exsoluted from the PNM film. The nanoparticles exhibit high oxygen vacancy concentrations that facilitate rapid ORR kinetics. The PNM film provides rapid oxygen ion transport to the LSCF surface and, in addition, enhances the stability of the cathode.

This well-designed approach to introducing a thin catalyst on a cathode backbone provides high performance and excellent stability and facilitates improved SOFC performance across a broad temperature spectrum.

- More stable: The technique used enhances cathode durability while maintaining the high-kinetic electrode structure

- Stackable: The cathode design is suitable for implementation in a fuel cell stack

- Fast: The combination of nanoparticles and conformal coatings provides increased reaction sites and rapid transport paths

- Solid oxide fuel cells

- Distributed energy generation

- Energy conversion

- Energy storage

- Electrolysis cells

Solid oxide fuel cells offer clean and efficient energy generation; however, their adoption is hindered by limited lifetime and high cost to fabricate and operate. One way to lower their cost is to enhance the ORR, particularly at lower temperature. Resistance during ORR contributes the most to energy loss in current SOFCs, and the problem is more pronounced at lower temperatures. The Georgia Tech innovation addresses these issues.