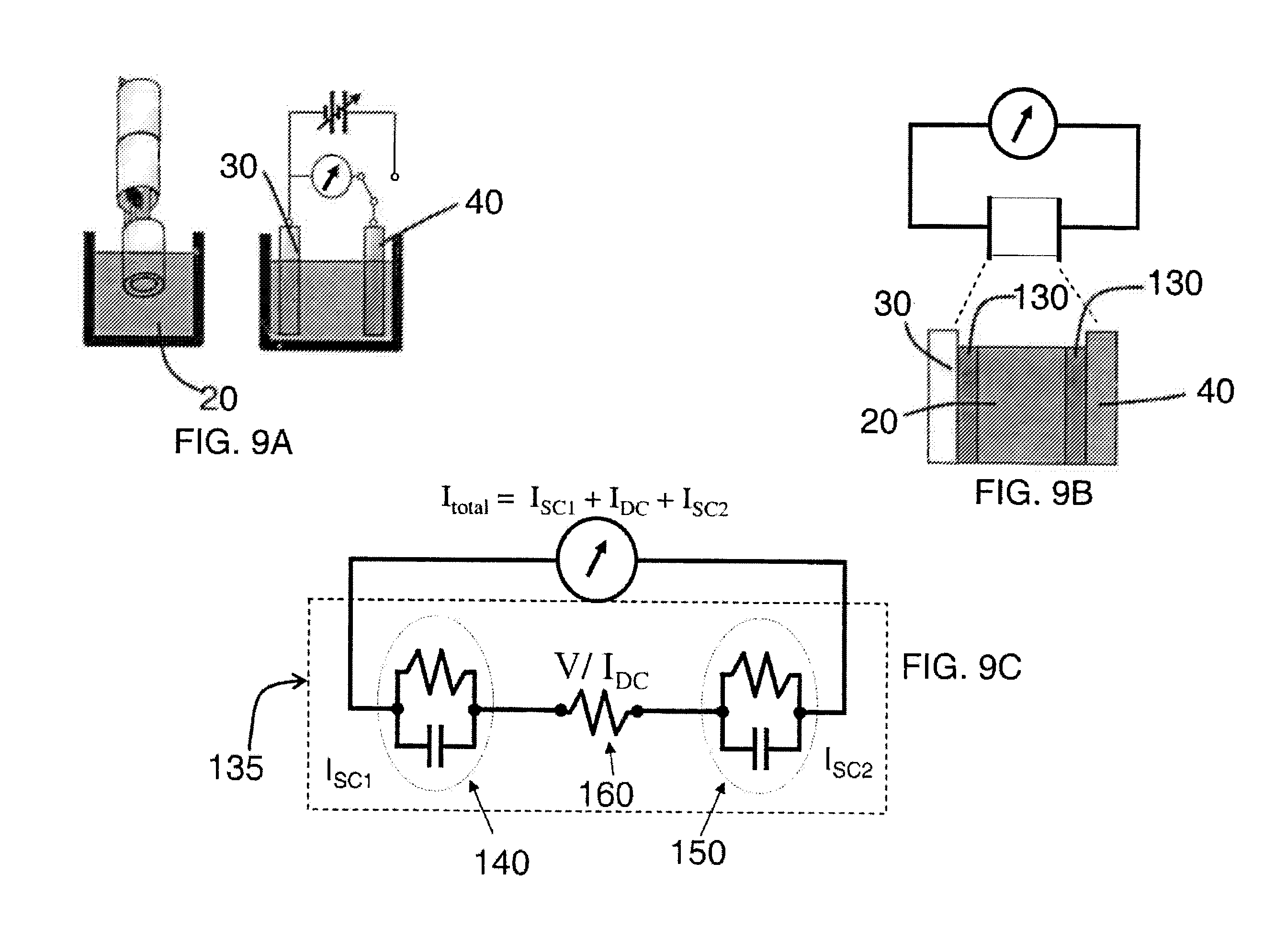

Georgia Tech inventors have designed a method to measure the electrochemical properties of hydrocarbon and other dielectric fluids to detect chemical degradation or contaminants. The technique is comprised of electrodes that generate an electrolytic current and a detection and amplification circuit. This method has broad applications for any system which requires production, processing, or use of a weakly-electrolytic fluid of well-defined chemical properties or use of a fluid with prescribed chemical properties with lack of contaminants for applications such as industrial operations and manufacturing. Systems include engines, transmissions, manufacturing operations and systems, and chemical plants and fluid-based processing systems.

- Broad applications — can be used for any system that uses weakly-electrolytic fluid

- Low cost — more accurate results prevent premature fluid changes

- Efficient — highly sensitive measurements in very short time periods

- Automotive

- Aviation

- Industrial

- Marine

- Agricultural

- Food industry

Numerous machines and systems, such as automobile engines and machines used in manufacturing, rely on lubricants and oils for carrying out their proper functions. Conventional systems do not monitor the actual properties of the fluid being employed while the systems are in operation. Typically, the fluids are either changed at preset intervals or samples of the fluids are extracted, sent for chemical analysis, and depending on the outcome, the fluids are changed. This can result in premature fluid change, which is very wasteful and costly, or delayed fluid changes which can cause low efficiency operation or unnecessary damage to a system. Some monitoring systems do exist but are either not very sensitive or too expensive to use.