Direct air capture (DAC) technologies, which extract CO2 directly from the air, are an important component of global strategies to mitigate climate change. Most systems use temperature swing adsorption (TSA) cycles with vacuum-assisted or steam-driven desorption systems, which cause complications with auxiliary equipment and the need for water management before and after the adsorbents are exposed to steam.

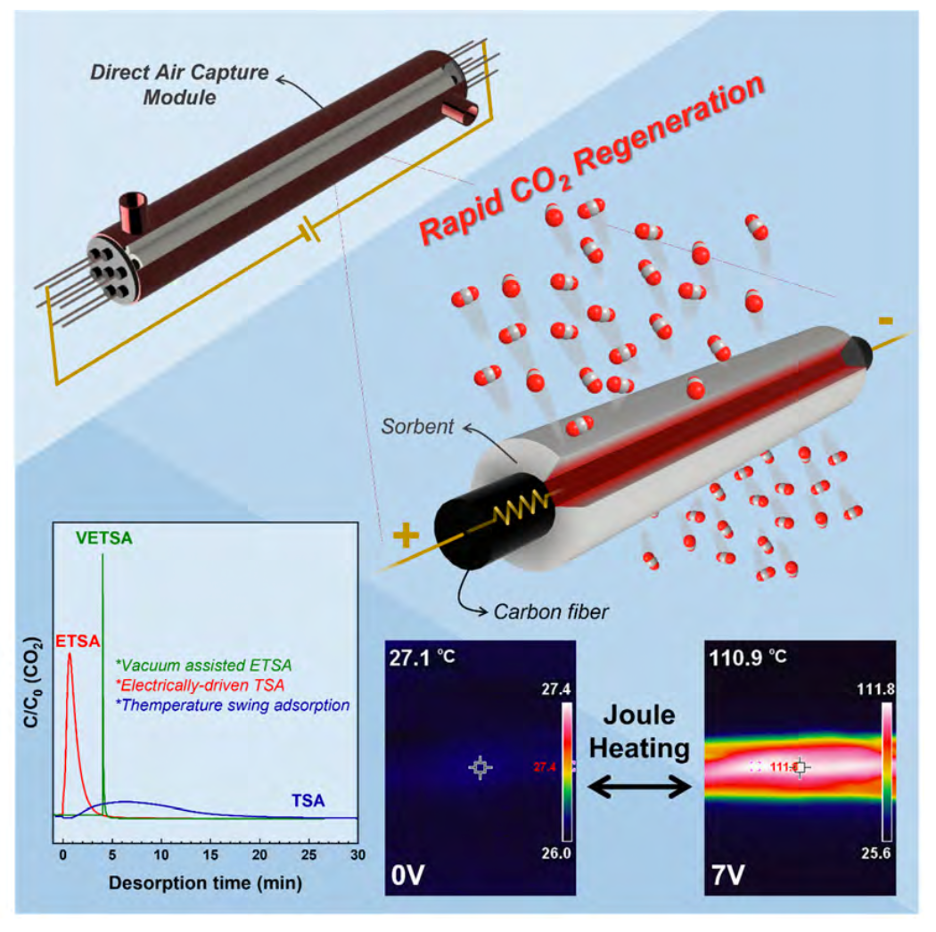

Electrically driven temperature swing adsorption (ETSA) systems improve energy efficiency and may enable smaller DAC systems. Renewable activated carbon materials in a DAC system that employs Joule heating (a process that converts electrical current into thermal energy) have the potential to reduce CO2 emissions. However, CO2 is only weakly adsorbed in this process, and the activated carbon materials do not have a high enough capacity to effectively capture CO2, especially in dilute CO2 conditions such as those found in direct air capture.

Sorbent coating on carbon fibers enables increased DAC productivity, releasing ~95% of adsorbed CO2 six times faster

This ETSA system uses sorbent-coated carbon fibers that exhibit Joule heating and rapid temperature swings for improved CO2 direct air capture. The sorbent-coated carbon fibers capture CO2 from ambient air at room temperature and desorb the CO2 simply by applying an electric potential to heat the fibers. The sorbent-coated fibers quickly respond to the electrical signal, enabling rapid CO2 regeneration. The ETSA module releases ~95% of adsorbed CO2 six times faster than externally driven thermal desorption.

The sorbent-coated carbon fibers use commercially available materials and a roll-to-roll coating system for simplicity and modularity. That, coupled with the rapid adsorption/desorption cycling by this ETSA, has the potential to improve the productivity of DAC systems relative to traditional temperature swing adsorption processes.

- Higher heat transfer rates: Joule heating results in higher heat transfer rates than indirect heating methods (e.g., external heaters, steam) and is potentially comparable to direct steaming methods.

- Faster: This technology provides more than ten times faster temperature controls and six times faster CO2 desorption rate in vacuum-assisted ETSA than TSA operation under the same DAC conditions.

- Larger capacity: The dual-layered structure composed of a Joule heating core and a CO2-adsorbing coating layer results in larger amounts of CO2 chemisorption to occur compared to other materials that employ Joule heating.

- Greater adsorption: Sorbent-coated carbon fibers adsorb CO2 from air or flue gas via chemisorption, capturing more CO2 even in dilute CO2 environments.

- Cleaner: This ETSA releases CO2 in pure form.

- Smaller systems: High heating rates eliminate the need for auxiliary water heaters and treatment systems, potentially resulting in smaller carbon capture systems than traditional temperature swing adsorption processes.

- Efficient: Its efficient heat management during the electrothermal desorption has the potential to reduce cooling energy needs.

Can be applied to CO2-capture fields such as:

- Direct air capture

- Post-combustion carbon capture

- Biogas upgrading

- Natural gas sweetening

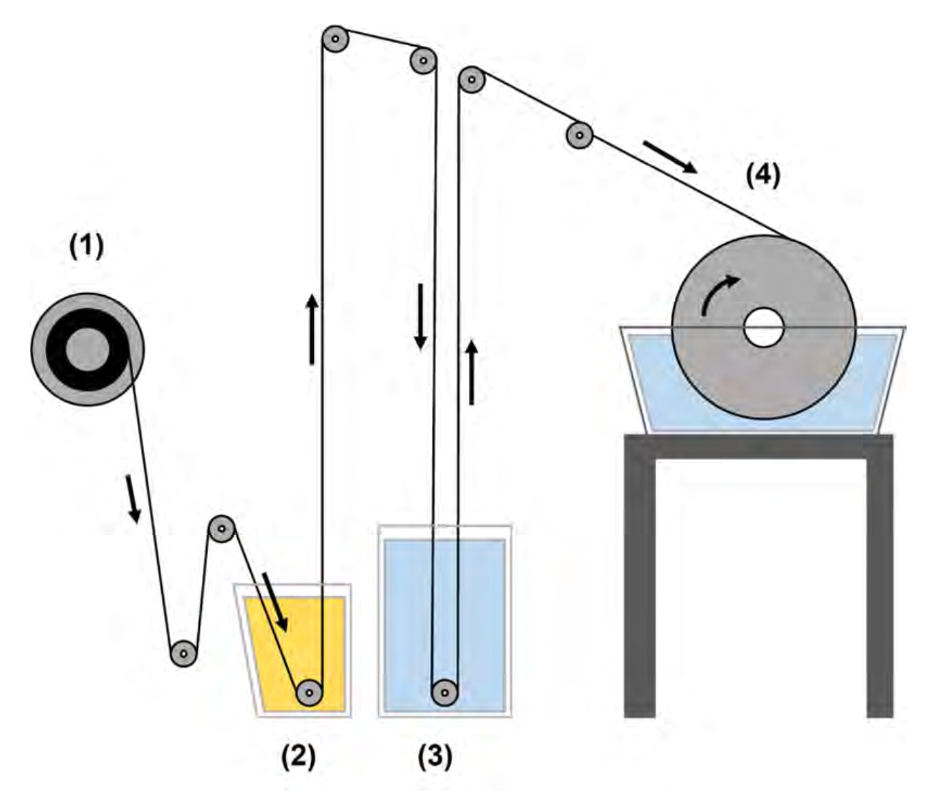

The roll-to-roll coating system: The carbon fiber moves from left to right following the arrows. The eight small doughnuts indicate rolling pullies. (1) Carbon fiber spool, (2) Dope container, (3) Water coagulation bath, (4) Take up bath

Illustrated direct air capture module shows carbon fibers coated with sorbent to adsorb and resorb CO2 using Joule heating.