This chip-scale technology produces an atomic beam with high collimation in a more easily manufactured and compact package. Developed by Georgia Tech, this atomic beam system offers greater long-term stability than vapor cell chip-scale systems and is produced in a smaller package than conventional Cesium (Cs) beam systems. It uses lithographically defined or machined planar wafers with internal cavities and channels to produce an evacuated vacuum package that houses a collimated atomic beam. Also incorporated are components to source atomic vapor as well as passive pumps to maintain vacuum conditions.

- Improved stability: Enables longer term stability than in traditional vapor cell chip-scale systems

- Smaller package: Utilizes a chip-scale system that is more compact than conventional Cs beam systems

- Easily manufactured: Uses lithographic fabrication to produce atomic beams with high collimation

- Precision timekeeping (e.g., chip-scale atomic clocks primarily used in cell phone base stations)

- Navigation (e.g., interferometers used in underwater oil and gas exploration)

- Robotics

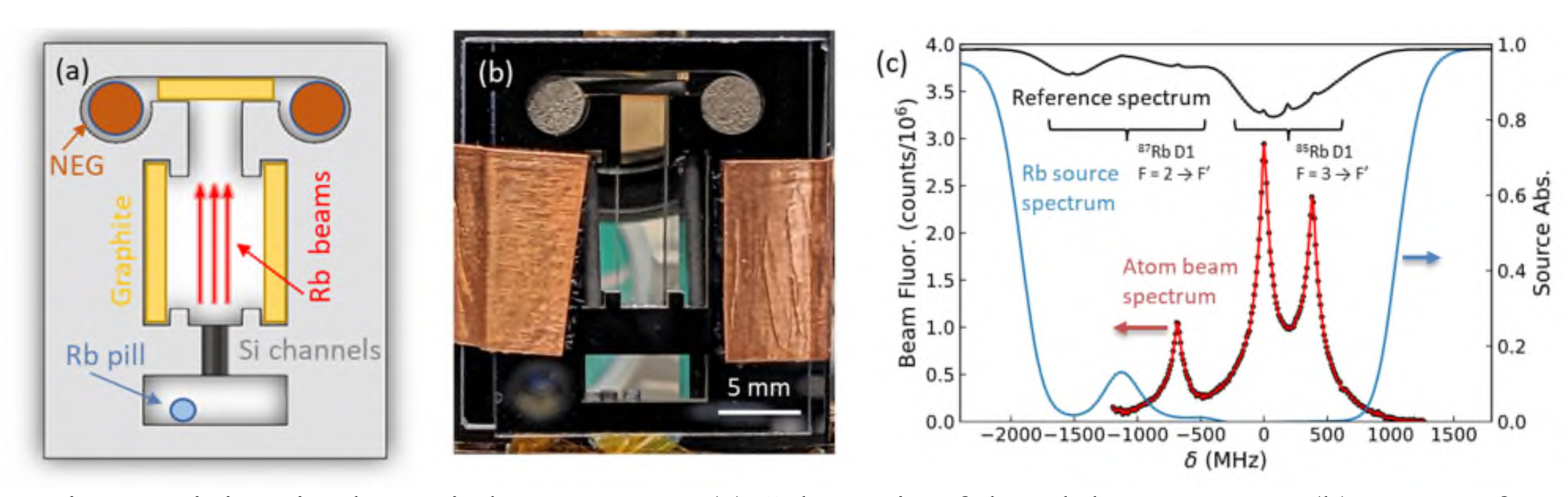

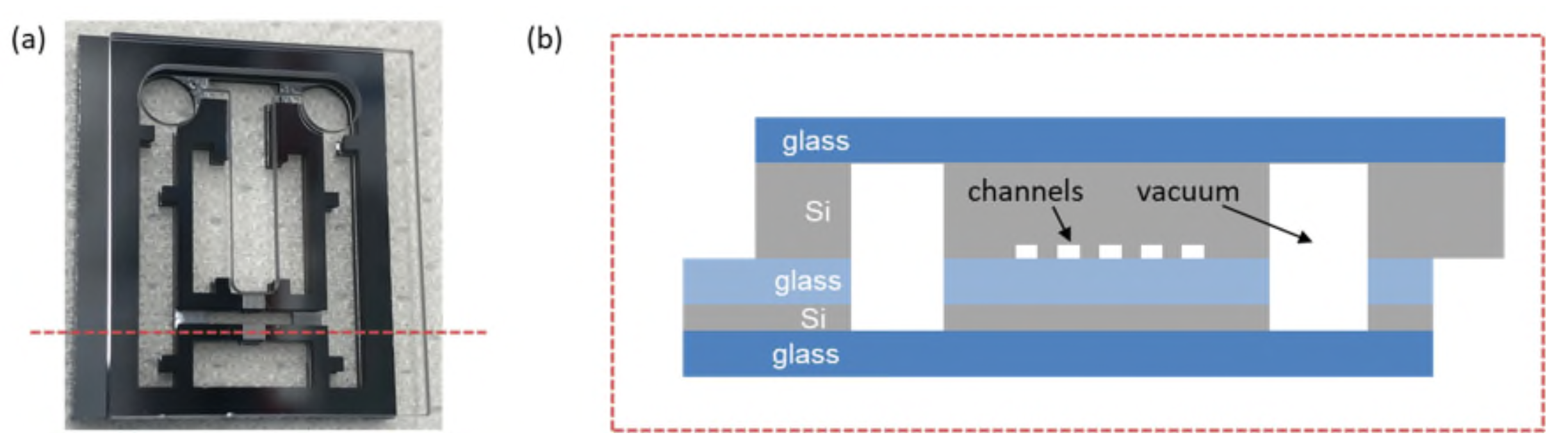

Current atomic beam systems (such as Cs beam tubes for atomic clocks) exist either in lab-scale vacuum systems or in custom vacuum tubes. Georgia Tech’s chip-scale system for producing atomic beams is composed of etched silicon and glass wafers that are anodically bonded under vacuum to form a hermetically sealed, evacuated device. The device consists of several chambers connected by high aspect-ratio channels to produce a collimated atomic beam. One chamber produces an atomic vapor, and another chamber provides a propagation volume for the atomic beam. Non-evaporable getter pumps and graphite are included to pump residual gases.

Miniaturized atomic beam source: (A) schematic of the rubidium (Rb) beam source; (B) image of assembled device; (C) Rb fluorescence spectrum measuring the transverse velocity distribution of the atomic beam and Rb absorption spectrum measuring the Rb vapor density feeding the channel array (a saturated absorption spectrum from a natural abundance Rb cell is included for reference)

(A) Atomic beam source during fabrication; (B) Cross-section of device along dashed line in “a” showing silicon and glass layers