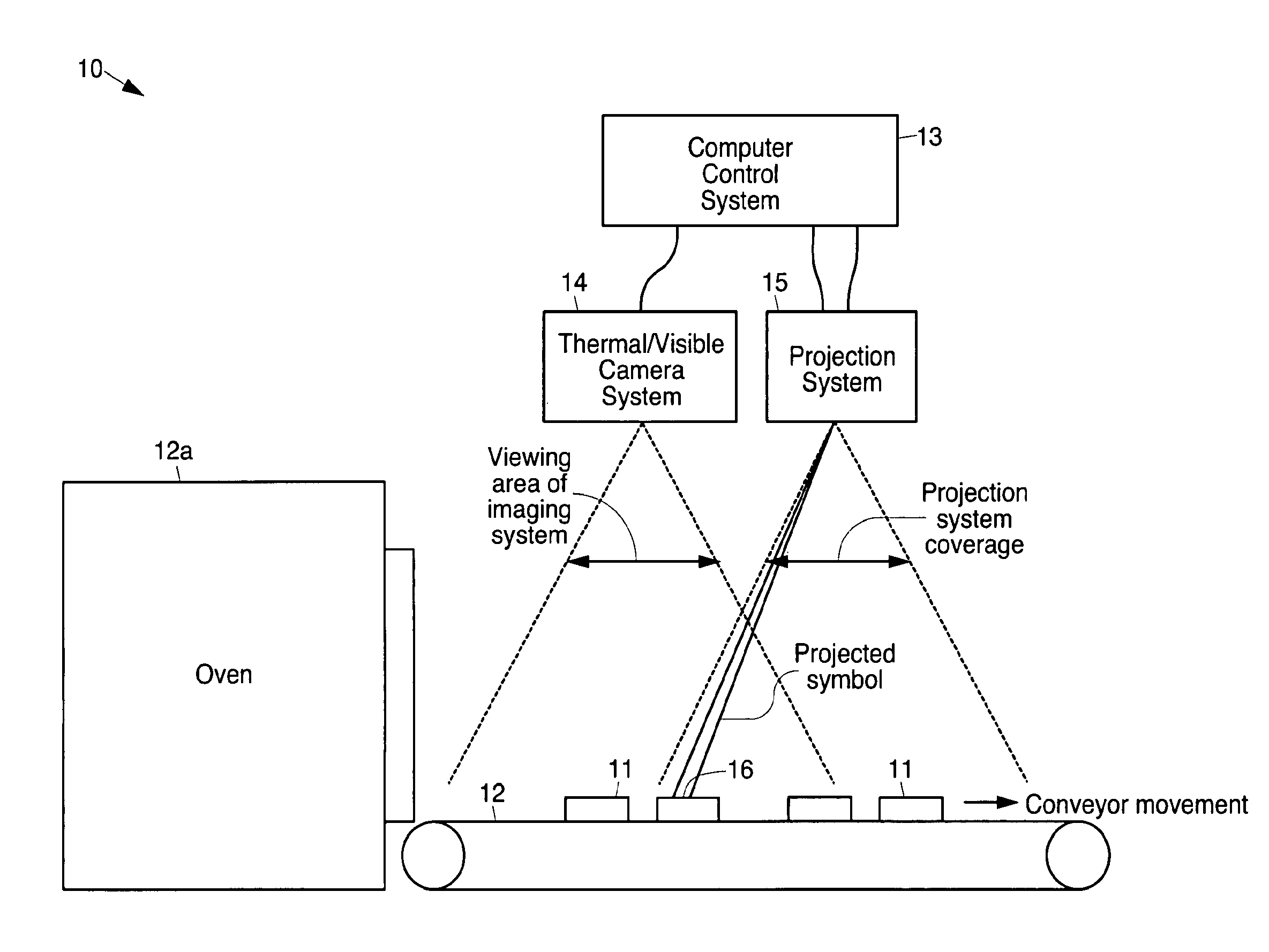

Georgia Tech researchers have developed an augmented reality vision-based system and method that monitors and controls baking, cooking, and routing processes. The system includes a projection display system or a laser projection system that is networked with an infrared or visible imaging system that improves the ability to monitor and control baking, cooking and routing processes. The system could be further enhanced by adding a barcode reader, a projection display system or a laser projection system, and an infrared or visible imaging system that are networked together and improve the ability to monitor and control baking, cooking, and routing processes.

- Reduces errors and labor involved in quality control

- Saves time and money

- Assists operators in identification of potential problems

- Eliminates label application step in product delivery

- Process oven-cooked and baked products

- Identifying products that are defective

- Processing packages with identifiable labels to display routing information

Current methods for ensuring quality of mass produced baked and cooked food products, as well as methods for labeling and routing products in a distribution center are labor intensive. Defective baking/cooking products are typically detected by an operator inspector and removed from the conveyor belt. In the case of routing processes, labels are applied to packages when they arrive at the distribution center and are used to route the packages to appropriate delivery trucks, which requires printing and applying thousands of labels.