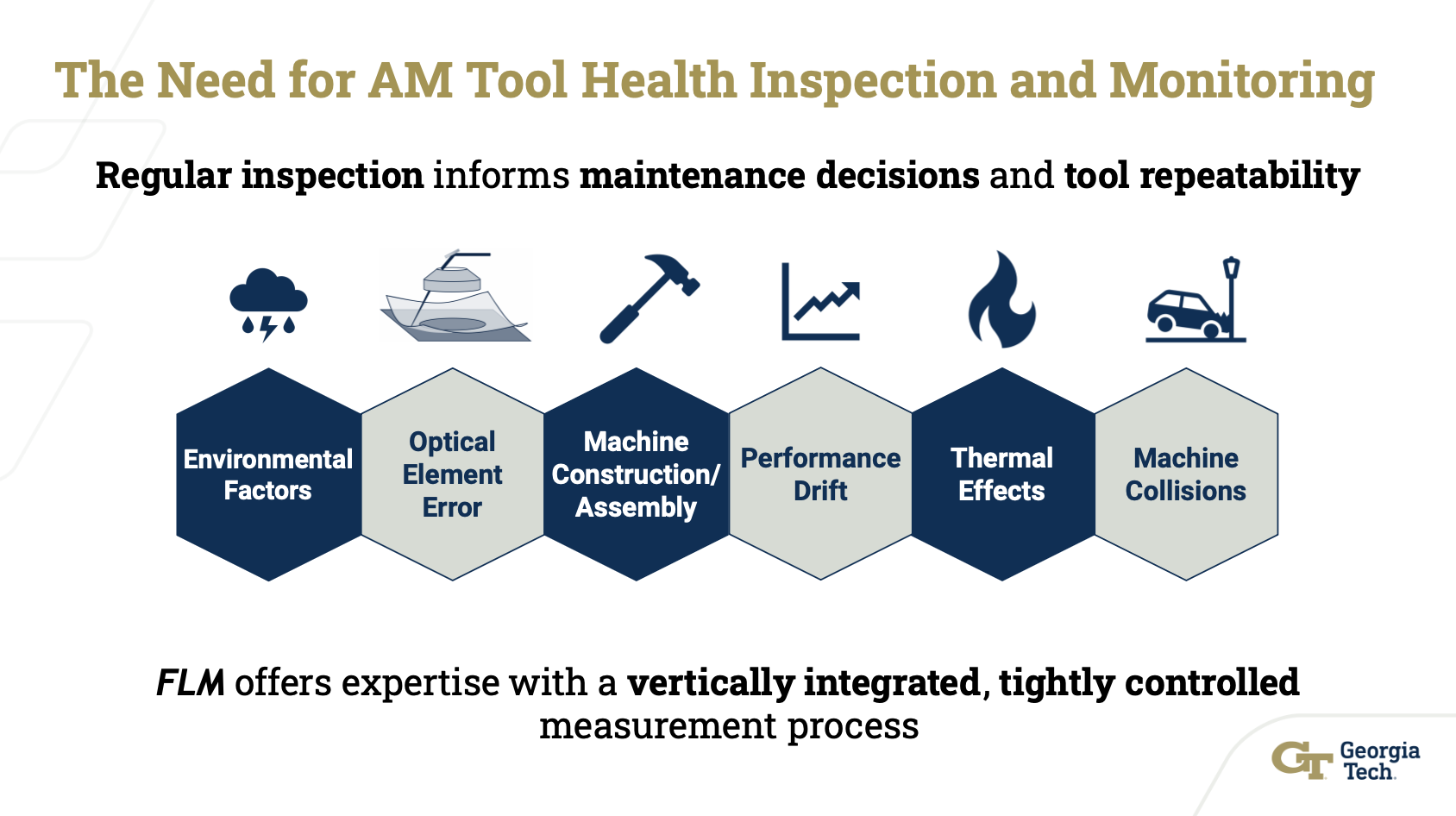

Performance of additive manufacturing (AM) machines is inconsistent

The global Additive Manufacturing (AM) market is rapidly expanding, driven by the demand for innovative solutions in production, prototyping, and customization across sectors like aerospace, automotive, healthcare, and consumer goods. However, challenges persist in ensuring the nominal performance of AM machines, which can result in compromised print quality, dimensional inaccuracies, and reduced efficiency. Current error detection methods, especially those for measuring focal errors in the optomechanical systems of laser powder bed fusion (PBF-LB) AM machines, are limited in their capability. The lack of appropriate error diagnostic methods can lead to subpar print quality, increased material waste, and manufacturing inefficiencies.

An error diagnostic method for improving AM machine precision

This method combines advanced techniques, models, and software to measure errors in the optomechanical system with precision. Using a pioneering method that utilizes the AM machine's laser to remove the coating from anodized aluminum coupons, this model makes it possible to determine the behavior of the laser beam across the entire build space of the machine. This capability is particularly effective in identifying and addressing focal errors that arise in laser powder bed fusion (PBF-LB) AM machines and these errors can be accurately pinpointed. The comprehensive approach includes measuring coupons, numerical analysis, and connecting results to a novel physics-based model. Manufacturers and users can diagnose errors with exceptional precision, thereby allowing improved machine performance and output quality if corrective action is taken.

- Precise error measurement: This technology provides accurate measurement of errors in the optomechanical system of AM machines and enables manufacturers to identify and address issues with exceptional precision, leading to improved machine performance.

- Focal error detection: By leveraging the AM machine's laser to remove a coating from aluminum coupons, this technology allows for the identification of focal errors, particularly in laser powder bed fusion (PBF-LB) AM machines, ensuring high-quality output and reducing the likelihood of defects in printed objects.

- Comprehensive approach for insightful analysis: This technology incorporates a comprehensive approach that relates empirical measurements to a novel theoretical model, providing valuable insights into the performance of the optomechanical system

- Additive Manufacturing Industry

- Quality Control and Assurance

- AM Research and Development

- AM Machine Maintenance and Servicing