The recycling of plastics has faced challenges for quite some time. Too stable to decompose quickly, plastics pollute the environment and are very costly to recycle.

Georgia Tech's startup Polymer Solutions, Inc. (PSI) is addressing this crucial issue. As a result of its technology transfer with Georgia Tech, PSI offers polymers that can transition from the solid state to the vapor state on command. This major innovation has the potential to revolutionize plastics recycling, enhance manufacturing processes and polymer-based compounds, and facilitate deep space travel.

The technology: A polymer that self-destructs on command

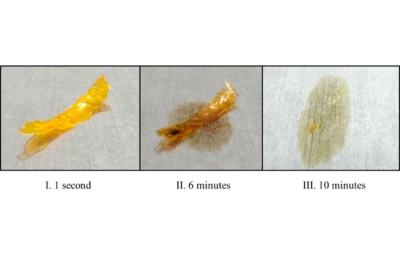

Leveraging Georgia Tech patents, PSI is commercializing a material that depolymerizes and disappears in response to a tunable stimulus or trigger, such as ultraviolet (UV) radiation, visible light, or heat. Common polymers, with ceiling temperatures far above ambient temperatures, are very stable and can only be decomposed through the breaking of thousands of bonds. Georgia Tech's patented phthalaldehyde-based polymers have a low ceiling temperature and are circular in shape, so they can be warmed to room temperature but do not degrade until triggered. Once triggered, only a single bond needs to be broken to start a chain reaction leading to complete depolymerization. The result is that Georgia Tech's polymers decompose quickly with significantly less energy. For more detailed information on how the patented polymers work, visit the Georgia Tech technology portfolio.

The licensee: Engineering polymers with degradation and recycling in mind

A faculty member at Georgia Tech for 33 years, PSI founder Dr. Paul Kohl has been involved in numerous research projects pertaining to polymer chemistry. Focusing on the development of these patented polymers for the past decade, Dr. Kohl launched PSI in 2020 and exclusively licensed the patents.

The team at PSI has more than 30 combined years of experience in the synthesis and engineering of decomposable polymers. They have been awarded patents for the materials, processing, and uses of aldehyde copolymers as well as published 16 peer-reviewed journal articles on their chemistry and engineering. The PSI team also has experience working with a variety of clients to help them replace plastics and processes with eco-friendly alternatives without sacrificing performance.

The impact of technology transfer: Faster, more energy efficient plastics recycling and more

As a result of the technology transfer between Georgia Tech and PSI, phthalaldehyde-based polymers are beginning to occupy a significant role in various applications. One major application is addressing the problem of recycling plastics.

Although catalysts exist that cause plastics to decompose, the issue has been how to incorporate the catalyst into the product when it is built. Not having the answer to this problem has meant being stuck with expensive methods to recycle cheap plastics.

PSI is working with the U.S. Department of Energy to encase these plastic-decomposing catalysts within Georgia Tech's patented polymer. When the polymer is triggered, it converts from a solid to a vapor, releasing the catalyst which, in turn, decomposes the plastic. The result is significant time and energy savings for recycling bulk components.

Beyond the groundbreaking potential effects on recycling, the rapid depolymerization and evaporation of polymers is useful for fabricating systems that have a fixed lifetime or targeted end-of-life. For example, the patented polymers are ideal for direct-write patterning applications, such as electron-beam, thermal scanning probe, and laser lithography. In semiconductor manufacturing processes where a placeholder is needed for part of the process, the polymers vanish when the placeholder is no longer needed. Another use is as disappearing adhesive tape, which could improve the assembly of solar cells.

The future

Applications for Georgia Tech's innovation promise to continue expanding into future markets at a growing rate as PSI advances manufacturing for commercialization.

For example, one exciting future avenue for the patented polymers is their potential to revolutionize space travel to Mars and beyond. When a satellite is launched into space, plastic components are needed at liftoff to stabilize delicate parts. However, after launch, these plastic parts are no longer needed and create space debris that must be tracked. With the use of this patented polymer, the UV light from the sun could trigger the polymer to rapidly turn into a gas that would then dissipate into the universe. Or, better yet, the polymer can be resynthesized and reused as a new component.

Recognition from the Cade Museum

On October 6, 2022, PSI tied for the fifth-place award for the Cade Prize for Innovation, receiving $3,000 cash plus $2,000 of in-kind legal services. Named after Dr. James Robert Cade, Gatorade's lead inventor, the Cade Prize is a capstone initiative of the Cade Museum for Creativity and Invention in Gainesville, Florida. Because moving early-stage ideas beyond the lab and into the marketplace often takes significant capital, the Cade Prize is designed to boost early-stage inventions to the next level. With the award, PSI will continue to expand their research and gain additional funding needed to achieve their goals and broaden the applications of Georgia Tech's groundbreaking technology.

The recycling of plastics has faced challenges for quite some time. Too stable to decompose quickly, plastics pollute the environment and are very costly to recycle.