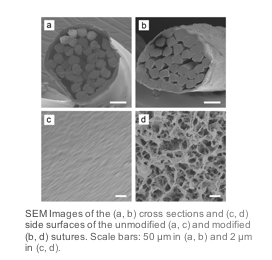

Georgia Tech inventors have developed a simple and versatile method for creating highly porous sutures which aim to accelerate the healing process of an injury site. These sutures are modified to contain an interconnected network of pores, serving to increase the volume of drug loading and allowing for the sustained release of the drug into the affected area. Compared to unmodified suture implants, the porous sutures have the same mechanical properties, but with enhanced drug loading capacity and a sustained release profile of the loaded drug. The modification process of the sutures is simple and conducted in liquid phase at room temperature with low-cost reagents, allowing for easy scale-up in commercial production. The porous sutures not only release drugs for anti-inflammatory, anti-microbial, and pain management purposes, but other bio-factors, such as growth factors, adhesives, extracellular matrix components, and cytokines, can be released to facilitate efficient tissue restoration and would healing. This novel invention also has great potential for the repair of load-bearing connective tissues, such as tendons, and can be readily extended to other applications for wound closure and long-term pain relief post-surgery.

- Accelerated wound healing and tissue regeneration through drug-eluting sutures

- Increased drug loading and sustained drug delivery due to the interconnected porosity feature of the sutures

- Release of cytokines, extracellular matrix proteins, anti-inflammatory, anti-microbial, and pain management drugs to injury site

- Mechanical properties of this novel suture are not compromised by the modification process

- Versatile platform for drug delivery in clinical applications

- Drug carriers for antibacterial wound closure

- Post-surgery pain-killing

- Growth factor-based tissue repair

The next generation of surgical suture manufacturing aims to combine mechanical function with drug delivery for improved and accelerated wound healing. These modified sutures not only have to retain their mechanical integrity for the duration of the healing process, but deliver the loaded drugs in a controlled, pre-designed fashion. Current drug loading mechanisms onto implants, however, only coat the drugs onto the surface of the sutures, resulting in a low loading capacity and a burst release profile of the drug.