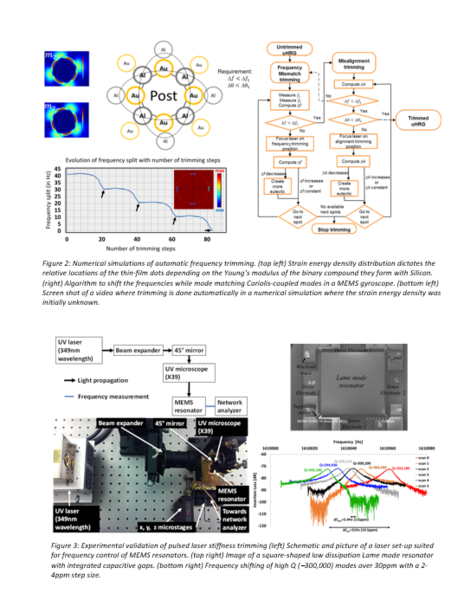

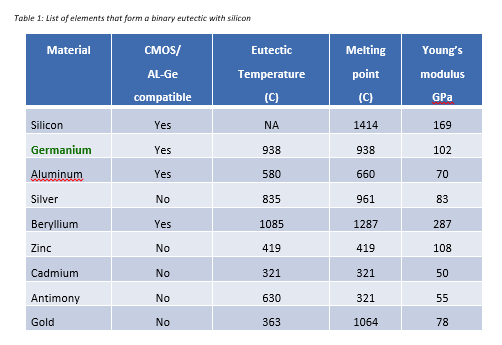

Georgia Tech inventors have developed a new method to optically trim the resonance frequency of a low-loss micromechanical silicon resonator coated with a thin-film germanium (Ge) layer. A focused UV laser beam locally heats Ge to high temperatures, enabling selective micro-crystallization of SiGe. The stiffness of the optically crystallized SiGe regions decreases with increasing concentration of Ge. These stiffness variations lead to an overall downward shift of the resonance frequency. Large trimming range is demonstrated for low-frequency out-of plane resonant modes. In addition, fine frequency trimming of in-plane Lame mode resonators is achieved without introducing any damping throughout the trimming process, enabling fine frequency control of high-Q micro-resonators. The resonance frequency of a trimmed germanium-coated silicon resonator remains stable after being heated to 450°C for 30 minutes in a Rapid Thermal Annealing (RTA) chamber. Deposition of Ge on Si and growth of SiGe crystals has not introduced any significant damping in low-loss bulk-mode resonators.

- High resolution stiffness trimming of high-Q Lame mode silicon resonators

- Stable frequency characteristics of Ge-coated Si resonators at high processing temperatures

- Achieves trimming without introducing any damping throughout process

- Material and set-up are foundry-friendly and can be scaled up

- Control the resonance frequency of resonators used in high-accuracy time keeping

- High-accuracy mass balance applications

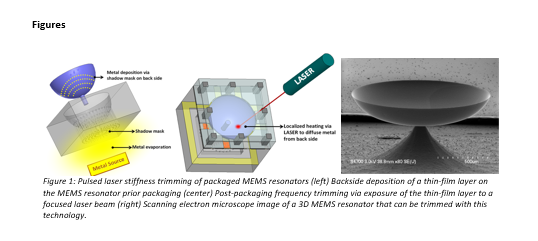

- Post-packaging trimming to compensate frequency variations

From burning candles that tracked time in pre-historic times to Quartz clocks that synchronize electrical signals in everyday circuits, timekeeping is at the heart of much of civilization’s progress. To date, Internet of Things (IoT), Vehicles, Wearables and many other sectors crave for clocks that are tiny, precise and low-power (i.e. longer lifetime). Ensuring that the frequency of the clock stays within its targeted range uses a lot of power and shortens the lifetime of the clock. There is a need for a robust design, low-power actuation, and permanent frequency control that will drive the clock.